Breathing bag convenient to take

A breathing bag and bag-shaped technology, applied in the field of easy-to-take breathing bags, can solve the problems of flat opening and inconvenient handling of breathing bags, and achieve the effects of increased strength, excellent tensile properties, and excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of breathing bag that is convenient to take, its production method comprises the following steps:

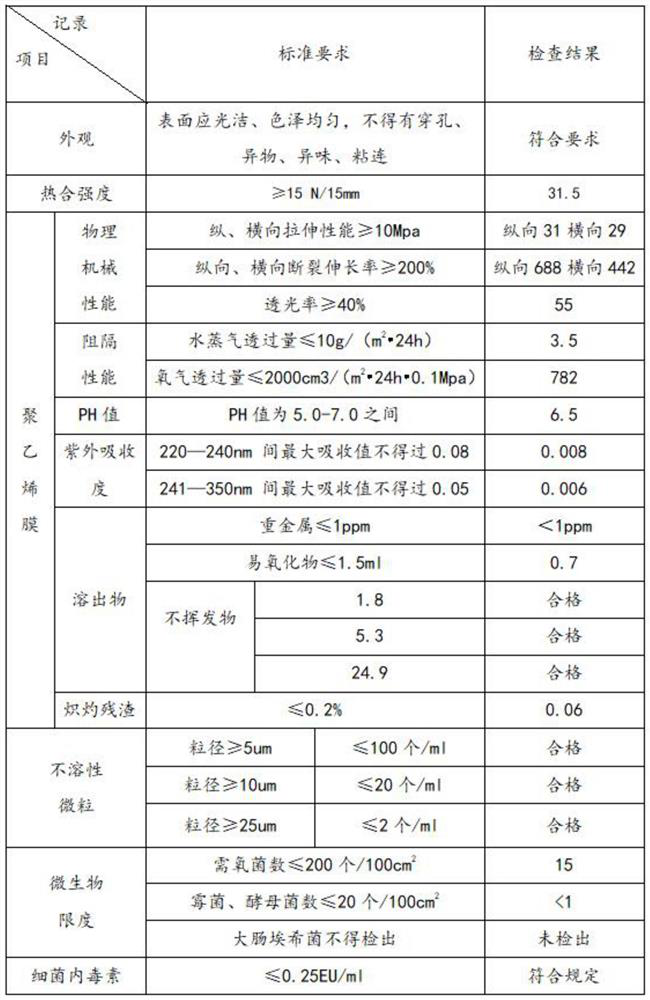

[0037] Step 1: Ingredients: the polyethylene film is composed of HDPE and LLDPE, wherein the density of HDPE is 0.945g / cm 3 , the content is 90%, the density of LLDPE is 0.920g / cm 3 , the content is 10%;

[0038] Step 2: Heating up: heat up the main engine in different zones through the heater, the temperature of the barrel area of the main engine is respectively: 180.0°C for zone 1-2, 190.0°C for zone 3, 180.0°C for zone 4-6, and the temperature of the die head The temperature in both zones is 170.0°C and keep warm for 1h after reaching the temperature requirement;

[0039] Step 3: Extrusion blow molding: When the main machine meets the heat preservation requirements, add raw materials to the hopper of the blown film machine, start the blown film machine, and the screw rotates at 10Hz at the beginning, when the molten material passes through the m...

Embodiment 2

[0046] Embodiment 2 A kind of breathing bag that is convenient to take, its production method comprises the following steps:

[0047] Step 1: Ingredients: the polyethylene film is composed of HDPE and LLDPE, wherein the density of HDPE is 0.950g / cm 3 , the content is 70%, the density of LLDPE is 0.925g / cm 3 , the content is 30%;

[0048] Step 2: Heating up: Heat up the main engine in different zones through the heater. The temperature of the barrel area of the main engine is: 185.0°C for zone 1-2, 195.0°C for zone 3, 180.0°C for zone 4-6. The temperature in both zones is 180.0°C, keep warm for 1.3h after reaching the temperature requirement;

[0049] Step 3: Extrusion blow molding: When the main machine meets the heat preservation requirements, add raw materials to the film blowing machine hopper, start the film blowing machine, the screw rotates at 13Hz at the beginning, when the molten material passes through the machine head and blows into a tube bubble, Gradually incr...

Embodiment 3

[0056] Embodiment 3 A kind of breathing bag that is convenient to take, its production method comprises the following steps:

[0057] Step 1: Ingredients: the polyethylene film is composed of HDPE and LLDPE, wherein the density of HDPE is 0.955g / cm 3 , the content is 50%, the density of LLDPE is 0.930g / cm 3 , the content is 50%;

[0058] Step 2: Heating up: heat up the main engine in different zones through the heater, the temperature of the barrel area of the main engine is respectively: 195.0°C for zone 1-2, 190.0°C for zone 3, 185.0°C for zone 4-6, and the temperature of the die head The temperature in both zones is 195.0°C and keep warm for 1.5h after reaching the temperature requirement;

[0059] Step 3: Extrusion blow molding: When the main machine meets the heat preservation requirements, add raw materials to the hopper of the blown film machine, start the blown film machine, the screw rotates at 15Hz at the beginning, when the molten material passes through the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| heat seal strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com