Low-carbon energy-saving noise reduction window

A technology for noise reduction windows and inner sashes, applied in windows/doors, door/window accessories, door/window applications, etc. It can reduce the power consumption of air conditioners and the ranking of pollutants and greenhouse gases, reduce carbon emissions, and achieve remarkable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

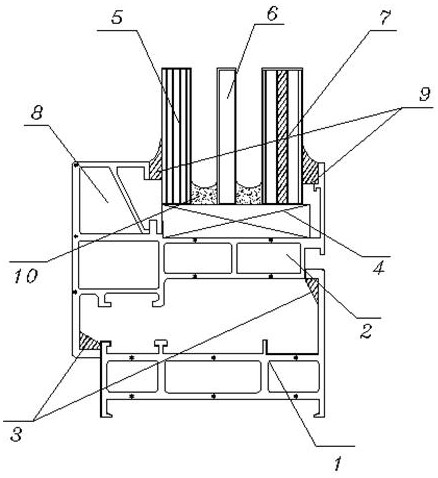

[0030] see figure 1 Among them, including the door frame 1, the inner leaf 2 is installed in the door frame 1, and the contact part between the door frame 1 and the inner leaf 2 is fixed with a silicone strip 3, and a rubber pad 4 is installed in the inner leaf 2; it also includes; vacuum glass 5, vacuum The glass 5 is installed in the inner cavity of the inner fan 2, and the inner fan 2 is fixed with a hollow glass 6 and a laminated glass 7, and the vacuum glass 5, the hollow glass 6 and the laminated glass 7 are arranged from the outside to the inside of the inner fan 2. and the vacuum glass 5, the insulating glass 6 and the laminated glass 7 are fixed in the inner fan 2 through the crimping line 8 and the silica gel pad 9, and there are soft edges fixed between the vacuum glass 5, the insulating glass 6 and the laminated glass 7 Article 10; the door frame 1, inner leaf 2 and pressing line 8 are all pultruded with glass fiber reinforced unsaturated polyester UP material, and...

Embodiment 2

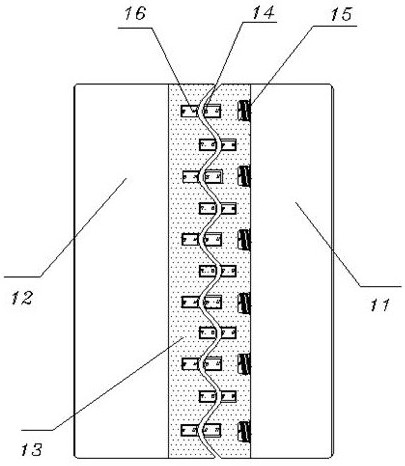

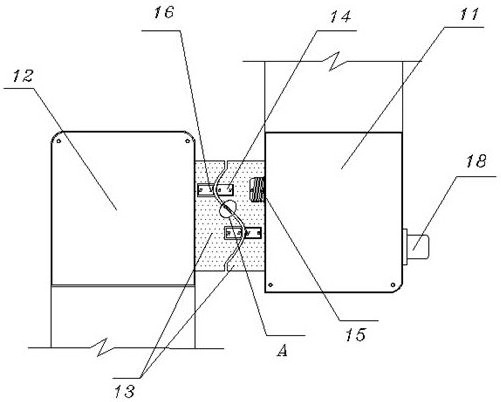

[0032] see Figure 2-4 Among them, the inner leaf 2 includes a first door leaf 11 and a second door leaf 12, and the first door leaf 11 and the second door leaf 12 are distributed on the inner and outer sides of the door frame 1, and the inner edges of the first door leaf 11 and the second door leaf 12 are all Adhesive sealing pad 13, first magnetic strip 14 and electromagnet 15 are embedded and fixed in the sealing pad 13 on the first door leaf 11, and the electromagnet 15 is fixed on the first door leaf 11, and the second door leaf 12 is sealed The second magnetic strip 16 is embedded and fixed in the cushion 13, and the side and top views of the sealing cushion 13 on the first door leaf 11 and the second door leaf 12 are designed in a sinuous structure, and the first door leaf 11 and the second door leaf 12 The sealing pads 13 on the top are concave-convex matched with each other, the first magnetic strip 14 and the second magnetic strip 16 are distributed at the concave-co...

Embodiment 3

[0034] see Figure 2-6 Among them, the inner side bolt of the first door leaf 11 is fixed with a handle 17, and the inner side of the handle 17 is connected with a pressure plate 19 through an embedded elastic telescopic rod 18, and a contact piece 20 is fixed on one side of the pressure plate 19, and the handle 17 is embedded Metal contact piece 21 is fixed, and metal contact piece 21 is positioned at the side of contact piece 20, and the outside of handle 17 is embedded with battery case 22, and the first door leaf 11 and the second door leaf 12 seal cushion 13 The outside is respectively fixed with a first locking bar 131 and a second locking bar 132, and the first locking bar 131 and the second locking bar 132 are located on the side close to the first magnetic bar 14 in the direction of the electromagnet 15. Both the tightening strip 131 and the second locking strip 132 are designed in a triangular structure, and the first locking strip 131 and the second locking strip 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com