Smoke-removing wave-absorbing flame-retardant device and underground protection engineering with smoke-removing wave-absorbing flame-retardant device

A wave-absorbing and smoke-inlet technology, applied in mufflers, exhaust devices, engine components, etc., can solve the problems of uneven performance of dust removal devices, depletion of oxygen, damage to equipment, etc., to reduce smoke exposure symptoms, Eliminate the effect of dissipative shock waves and maintain stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

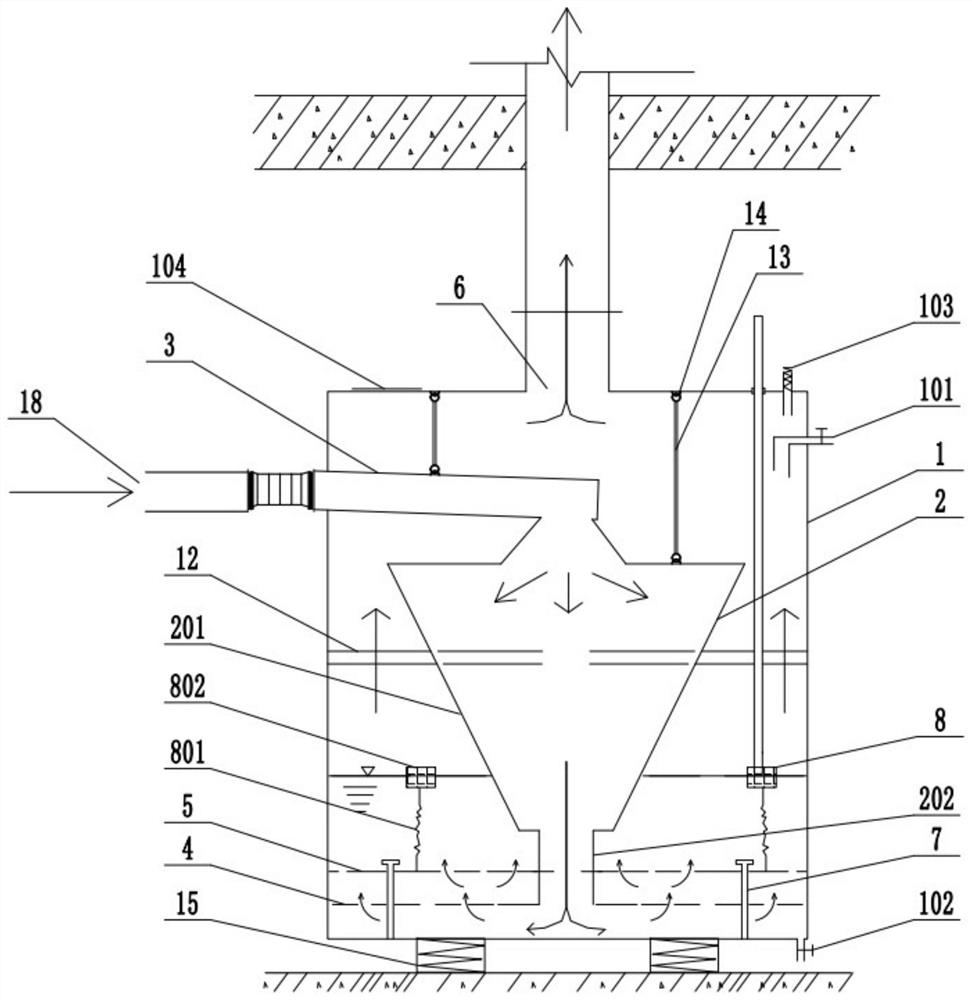

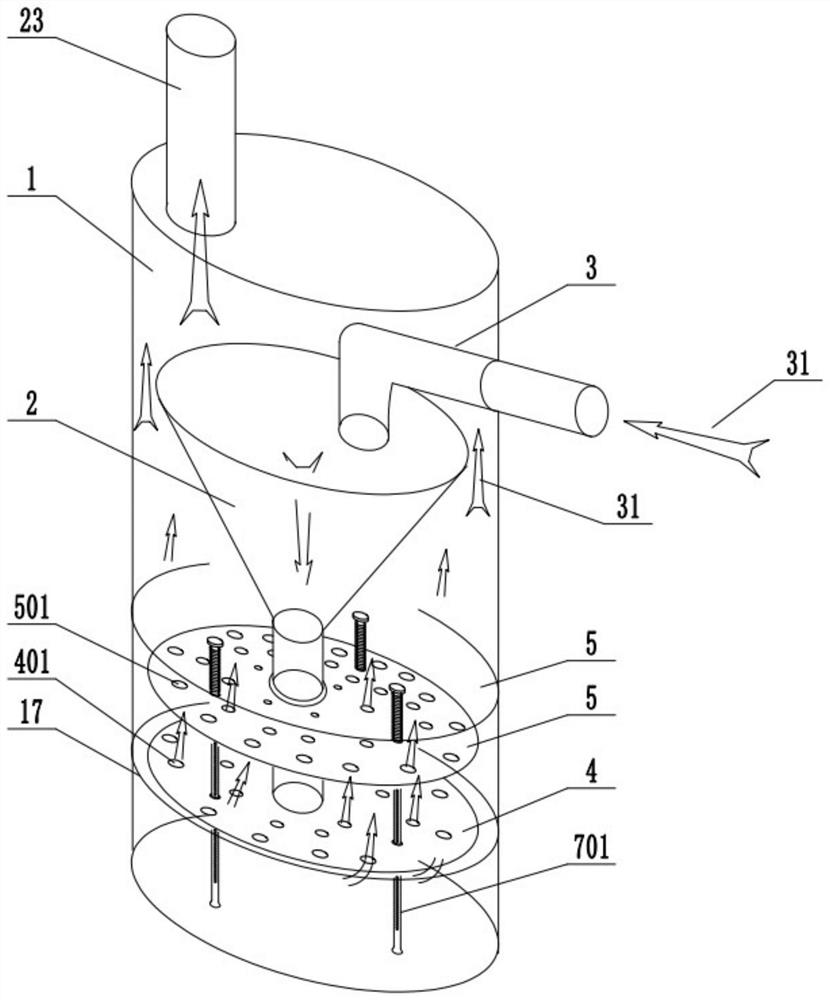

[0038] like Figure 1-2 The shown smoke and wave elimination and flame retardant device includes an outer box 1, an inner box 2, a smoke inlet pipe 3, a fixed plate 4 and a moving plate 5; the inner box 2 is arranged in the outer box 1, and the inlet One end of the smoke pipe 3 is located outside the outer box 1, and the other end passes through the side wall of the outer box 1 and communicates with the inner box 2. The inner wall extends, the outer diameter of the fixed plate 4 is slightly smaller than the inner diameter of the outer box 1, the fixed plate 4 is spaced from the bottom of the outer box 1, the moving plate 5 can be floatingly arranged above the fixed plate, the bottom plate of the outer box 1, The fixed plate 4 and the movable plate 5 are parallel to each other, and the diameter of the movable plate 5 is equal to that of the fixed plate 4 . The fixed plate 4 has a plurality of first air holes 401, and the moving plate 5 has a plurality of second air holes 501, ...

Embodiment 2

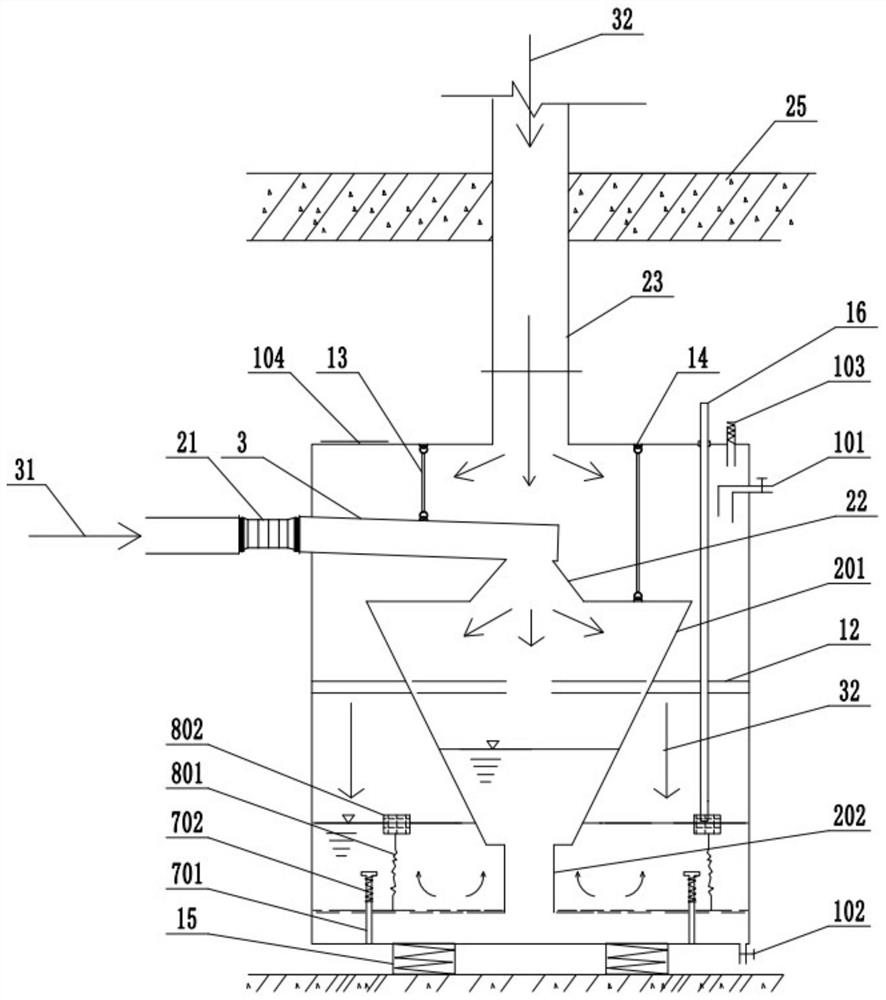

[0059] This embodiment is the same as embodiment 1 except the following technical features:

[0060] like Figure 7 As shown, in this embodiment, the smoke removal, wave elimination and flame retardant device is combined with the smoke exhaust diffusion chamber 9, the smoke exhaust port 6 is opened on the side wall of the outer box 1, and the side wall of the smoke exhaust diffusion chamber 9 is adjacent The upper part of the empty wall is directly connected with the smoke exhaust port 6, and the smoke exhaust port 6 is provided with evenly distributed holes 29 to facilitate the flow of smoke. An openable and closable wave absorbing mechanism 11 is provided outside the outlet 10 . The wave breaking mechanism 11 includes a wave breaking plate, the upper end of the wave breaking plate is connected to the side wall hinge of the discharge port, and the lower end of the discharging port is provided with an L-shaped limit hook 1102 to limit the opening range of the wave breaking pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com