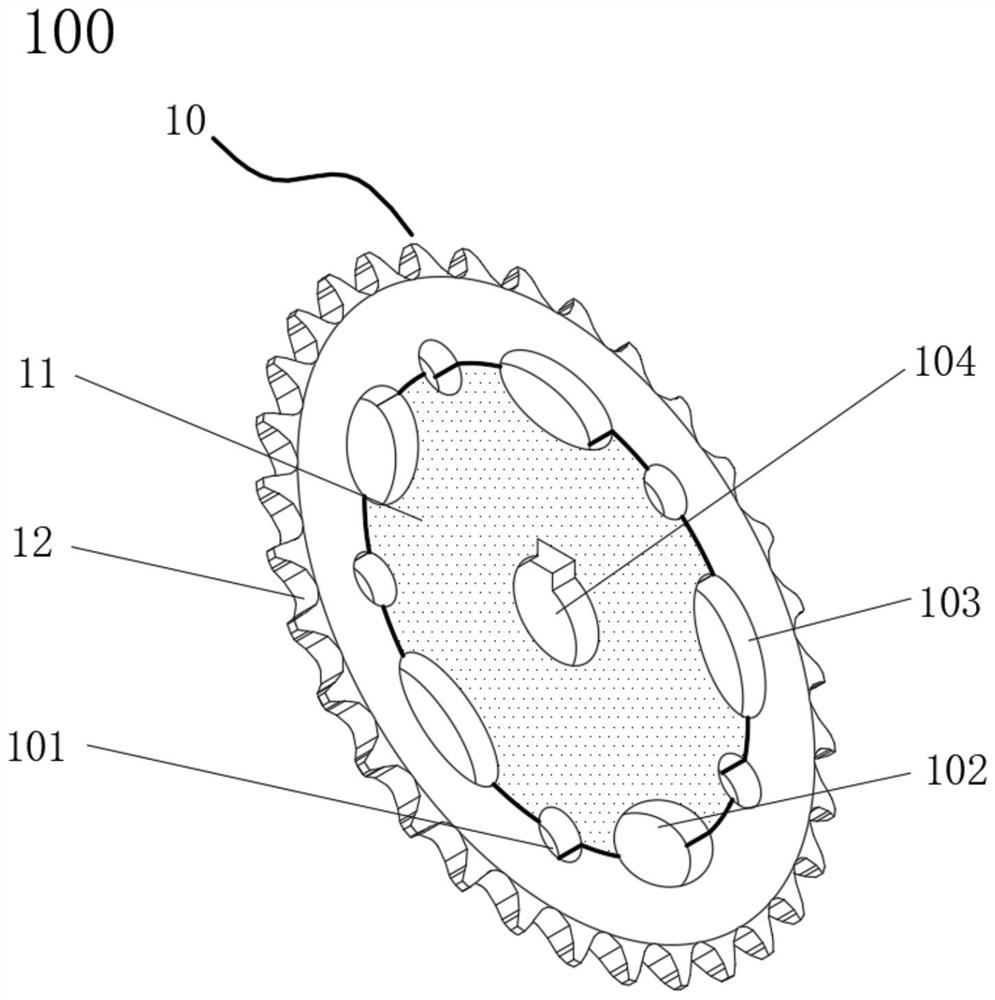

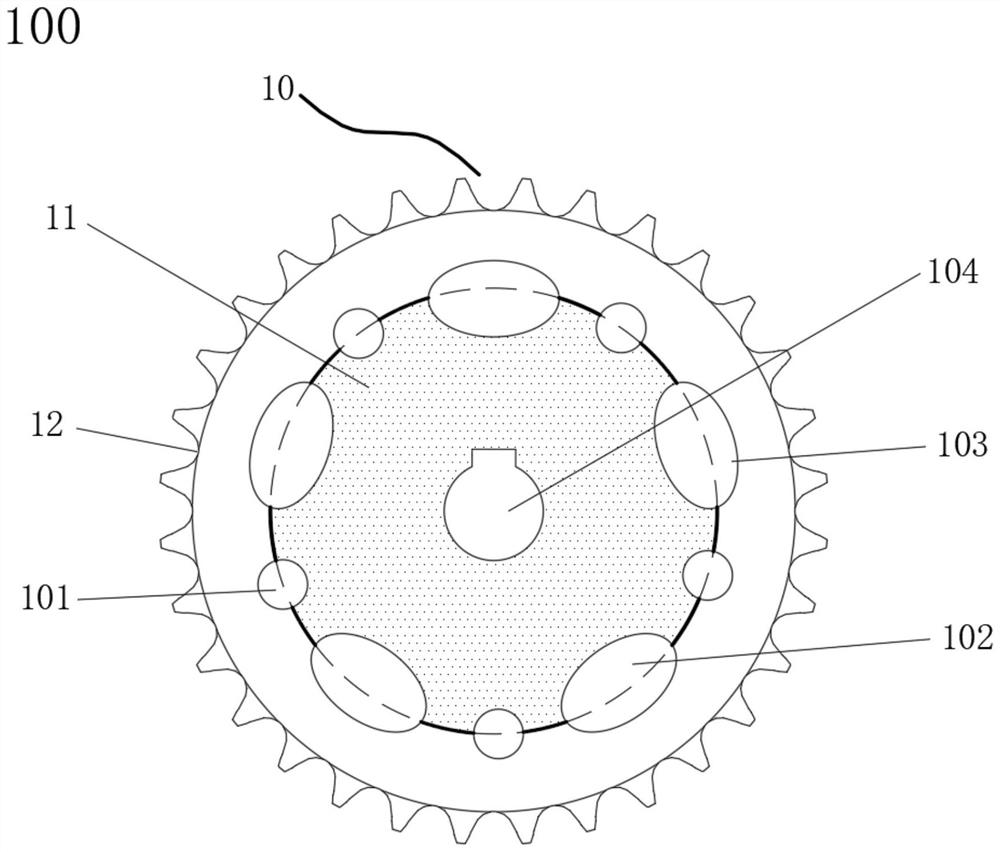

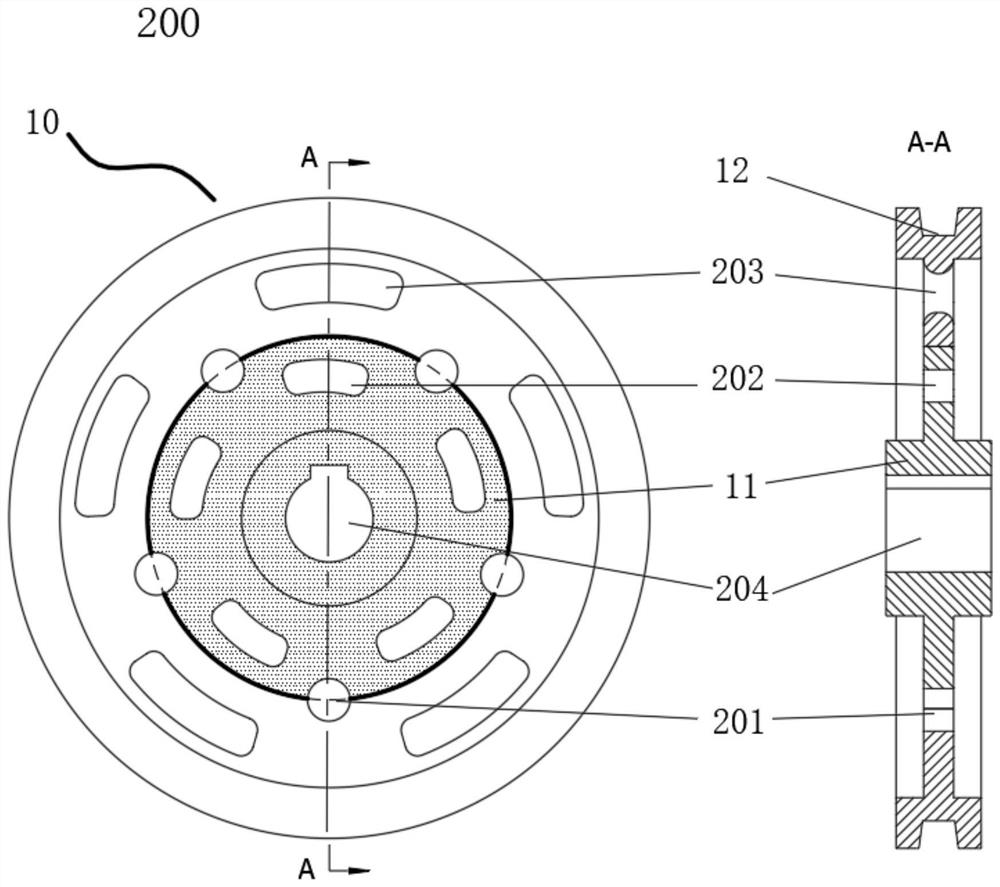

Lightweight aluminum matrix composite transmission disc for chain and belt transmission device

A technology of aluminum-based composite materials and belt transmission, which is applied in hoisting devices, components with teeth, portable lifting devices, etc., can solve problems such as short response time, heavy transmission disc, and large moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Material: aluminum alloy AA6061 powder (average particle size 32 microns, volume ratio 85%), strengthening phase B 4 C powder (average particle size 14 microns, volume ratio 15%).

[0037] Process, using powder hot pressing method (HIP or HVP method): (1) AA6061 powder and B 4 C powder mixing (Mixing and Blending). Wherein the aluminum alloy powder can be the aluminum alloy powder made by the existing aluminum alloy, or the powder of various components in the aluminum alloy can be mixed with the strengthening phase powder according to the proportion in the aluminum alloy base material. The aluminum alloy substrate is formed during the sintering process of the AMC. The same is true for the formation of aluminum alloy substrates in the following examples. (2) Put the homogeneously mixed AMC mixture into a can-type metal mold (Canning) that can be closed and has an exhaust pipe, and degas (Degassing / Evacuation). (3) Heat the pumped pot mold with AMC mixture to the spec...

Embodiment 2

[0039] Material: aluminum alloy AA6061 powder (average particle size 32 microns, volume ratio 75%), strengthening phase B 4 C powder (average particle size 12 microns, volume ratio 25%).

[0040] Process, using powder isostatic pressing sintering method (CIP method): (1) AA6061 powder and B 4 C powder mixing (Mixing and Blending). (2) Put the uniformly mixed AMC mixture into a rubber mold with an air outlet pipe, pressurize the rubber mold with the AMC mixture at room temperature, and then remove the outer rubber mold to obtain AMC powder ingot (Cold Isostatic Processing) . (3) Heat the AMC powder ingot in a vacuum furnace to the specified AMC sintering temperature, 550°C, to become an AMC ingot, and finally obtain the aluminum matrix composite material B.

Embodiment 3

[0042] Materials: aluminum alloy AA6082 aluminum ingot (average particle size 60 microns, volume ratio 95%), strengthening phase SiC powder (average particle size 30 microns).

[0043] The process uses the spray molding method (Spray method): (1) After melting the AA6082 ingot, it is sprayed downward through the powder injection device, and at the same time, the SiC powder is sprayed into the aluminum alloy powder, and the aluminum alloy powder and SiC powder are controlled. The volume ratios are 95% and 5%. (2) The mixed powder is deposited and solidified in the collecting device below, and the aluminum matrix composite material C is finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com