Plastic liner drying tank

A drying tank and liner technology, which is applied in drying, dryers, dryers for static materials, etc., can solve the problems of uneven heating, difficult processing and installation, and complicated working environment, so as to achieve easy disassembly and assembly. Effects of maintenance, improvement of corrosion resistance, and reduction of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

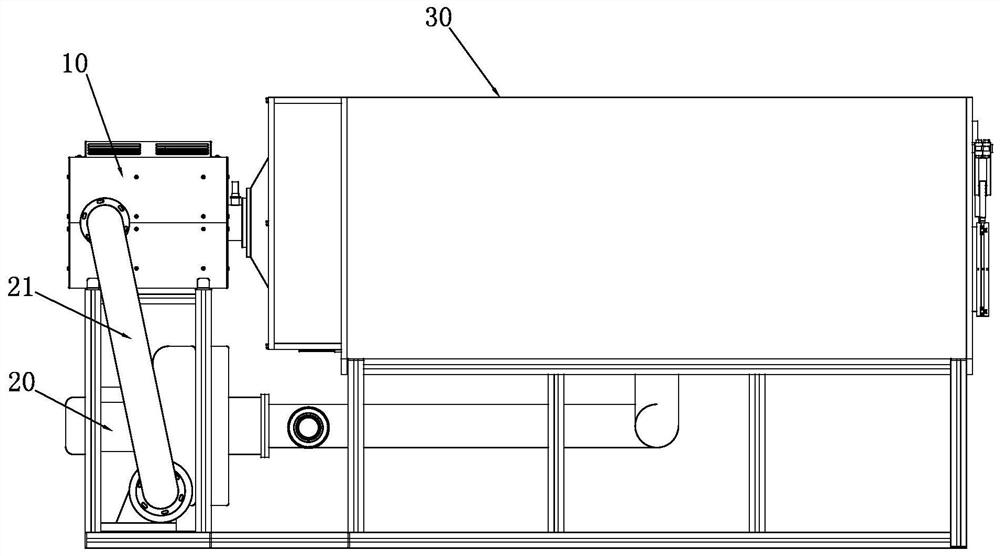

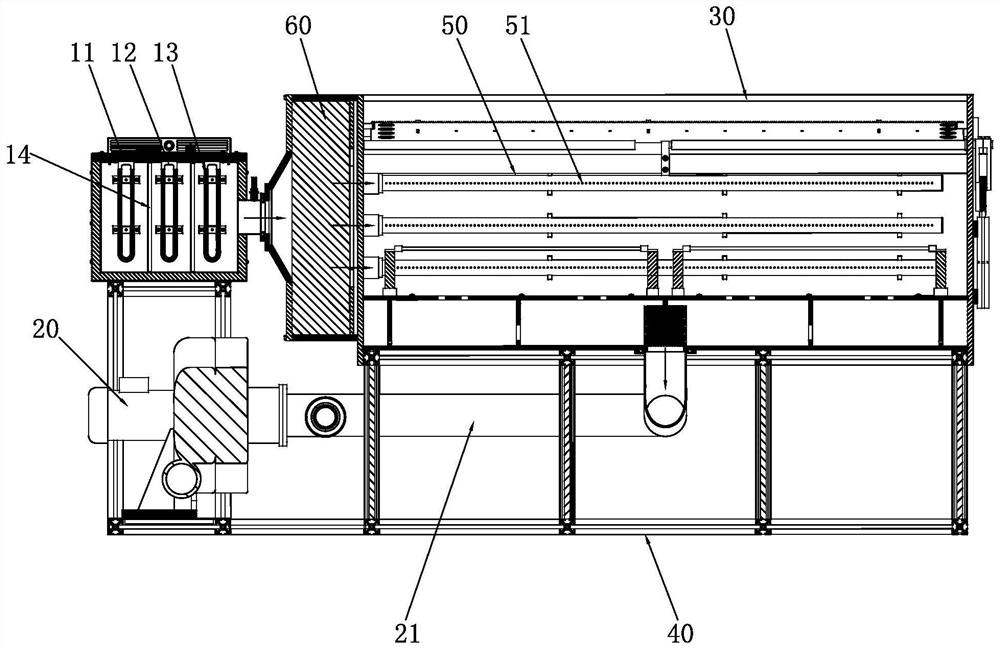

[0027] refer to Figure 1-3 The plastic liner drying tank provided by the present embodiment 1 includes a support frame 40 made of PVDF profiles, and the upper side of the support frame 40 is horizontally arranged with interconnected heating boxes 10 and tanks 30. On the support frame 40, there are also The fan 20 positioned at the outside of the heating box 10 and the tank body 30 is installed, the air inlet of the fan 20 is connected to the air outlet at the bottom of the tank body 30 through the air duct 21, and the air outlet of the fan 20 is connected to the inlet of the heating box 10 through the air duct 21. Tuyere; the inner wall of the tank body 30 is provided with a PVDF material liner 31 , and the upper side of the tank body 30 is provided with an openable cover plate 32 .

[0028] In this embodiment 1, the liner 31 inside the tank body 30 is designed and processed by PVDF material, and the support frame 40 is made of PVDF profiles. The mechanical properties of the...

Embodiment 2

[0030] Based on Example 1, refer to figure 2 , 4 And 5, in the present embodiment 2, heating box 10 comprises box body 11, and the side wall of box body 11 is provided with air outlet; Box body 11 inside is vertically provided with two dividing plates 14 and the interior space of box body 11 is separated by S-shaped connected three-stage heating area, and the three-stage heating area is close to the tank body 30 from outside to inside, the air inlet of the heating box 10 is set on the side wall of the outermost heating area, and the air outlet on the side wall of the box body 11 is set on The side wall of the innermost heating area is also connected to the tank body 30; the inside of the box body 11 is also equipped with heating components respectively located in the three-stage heating area; the box body 11 is a hollow interlayer structure, and the hollow interlayer of the box body 11 is filled with Heat insulation cotton, heat insulation cotton makes the external heat radi...

Embodiment 3

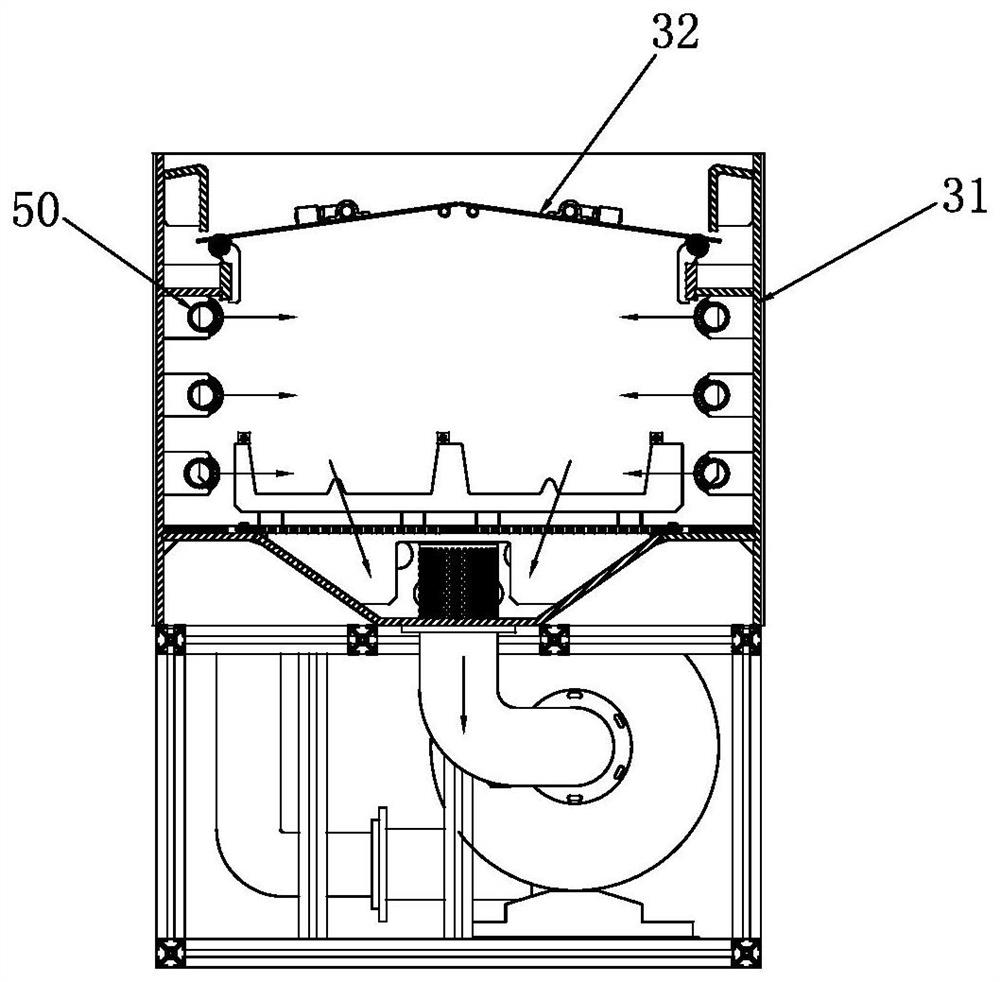

[0033] Based on Example 2, refer to Figure 2-3 , in this embodiment 3, the inner side of the tank body 30 is also symmetrically provided with a hot air nozzle 50 located inside the liner 31 and three hot air nozzles 50 are arranged in parallel up and down on each side, and the air inlet of the hot air nozzle 50 is connected to the box body 11 The air outlet, and the side wall of each hot air nozzle 50 is provided with at least one row of air outlet holes 51 aligned with the heating space inside the box body 11 .

[0034] In this embodiment 3, the original blower 20 is changed to the current hot air nozzle 50 to blow air to form an air curtain, and three hot air nozzles 50 are arranged symmetrically on both sides to blow air evenly so that the hot air circulation inside the tank body 30 is distributed. More uniform, the heating of silicon wafers and other products is more uniform, and the drying efficiency is higher, thereby improving the production capacity of the equipment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com