Array substrate, preparation method thereof and display panel

A technology of array substrates and metal layers, which is applied in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., can solve the problems of width-to-length ratio limitation and inflexible adjustment, and achieve the effect of adjusting characteristics and flexible characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. In the drawings, for clarity and ease of understanding and description, the size and thickness of the components shown in the drawings are not in scale.

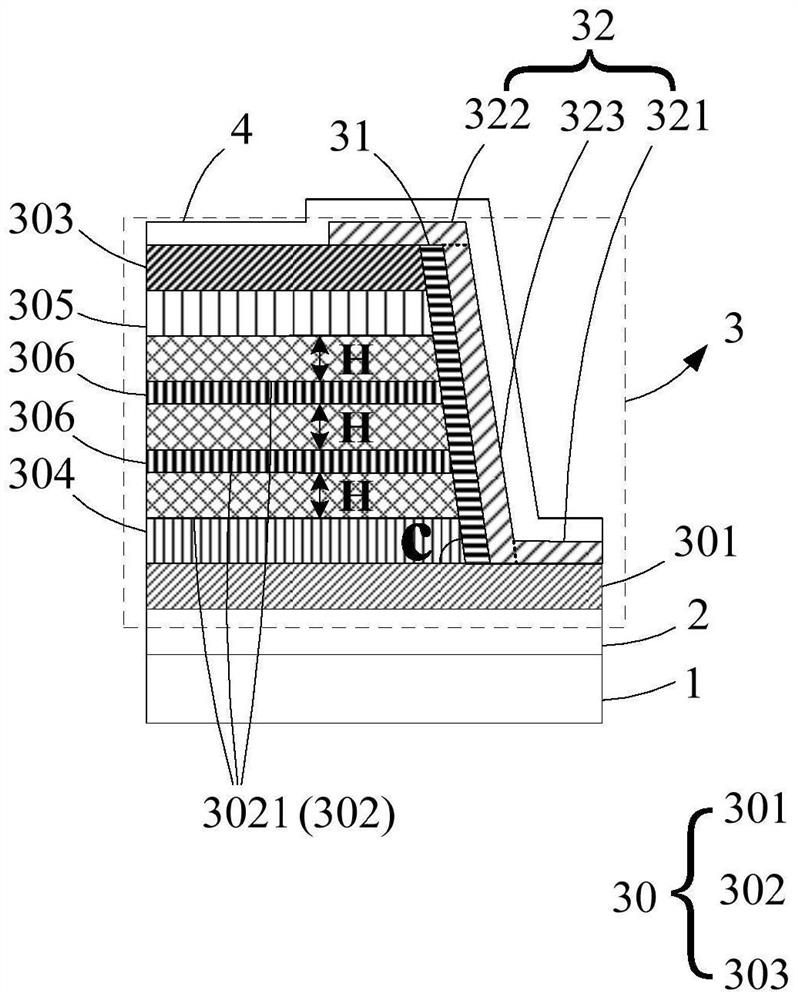

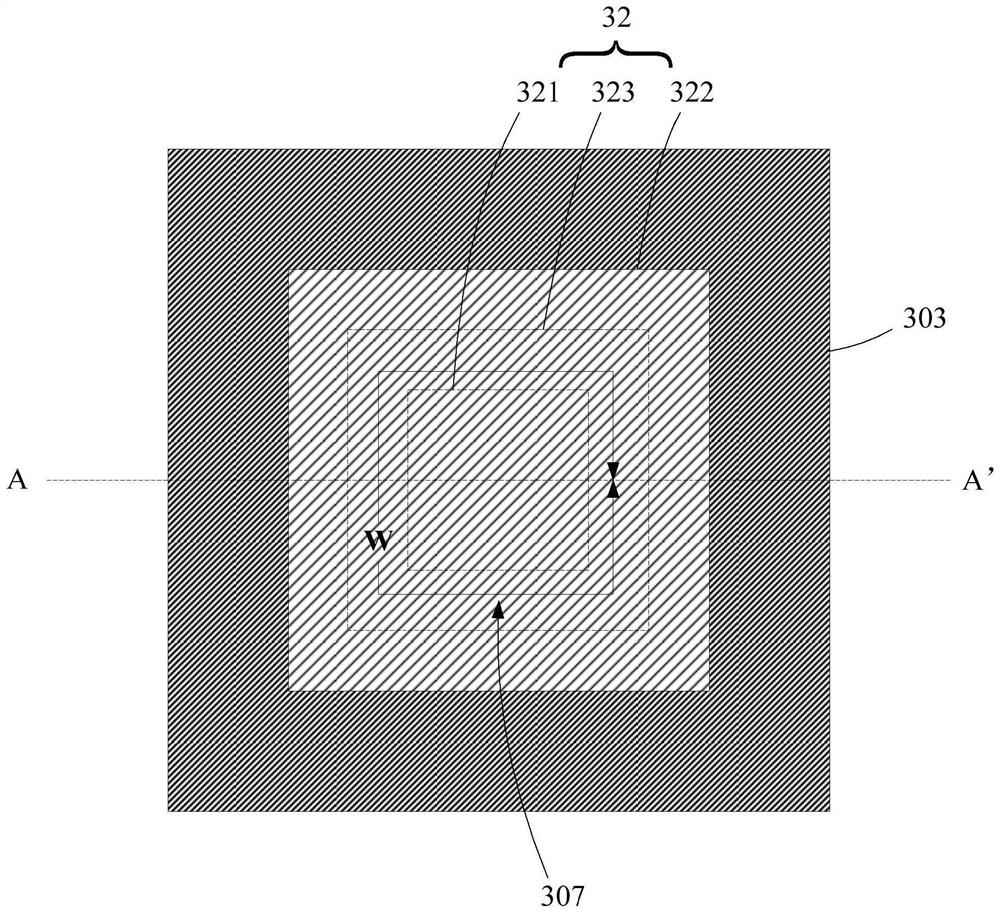

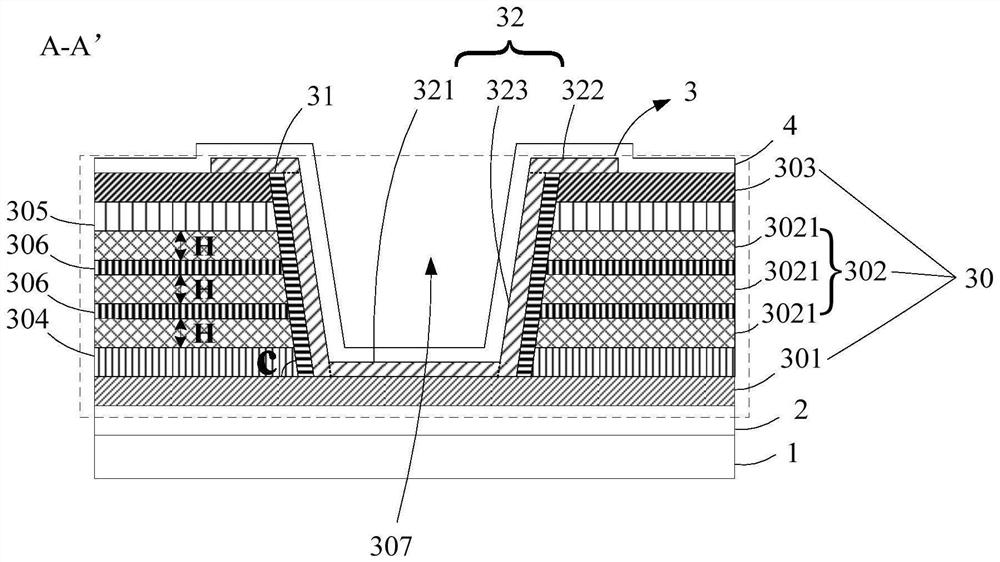

[0036] Such as figure 1As shown, it is a schematic diagram of the basic structure of the array substrate provided by the embodiment of the present invention. The array substrate includes a substrate layer 1 and at least one thin film transistor 3 located on the substrate layer 1; wherein, the thin film transistor 3 includes an electrode layer 30, a gate insulating layer 31, and an active layer 32; the electrode layer 30 includes a stacked first metal layer 301, a second metal layer 302, and a third metal layer 303, and the second metal layer 302 is respectively connected to The first metal layer 301 and the third metal layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com