Solar cell module and manufacturing method thereof

A solar cell group and solar cell technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of improving work performance, improving utilization rate, and improving sunlight utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

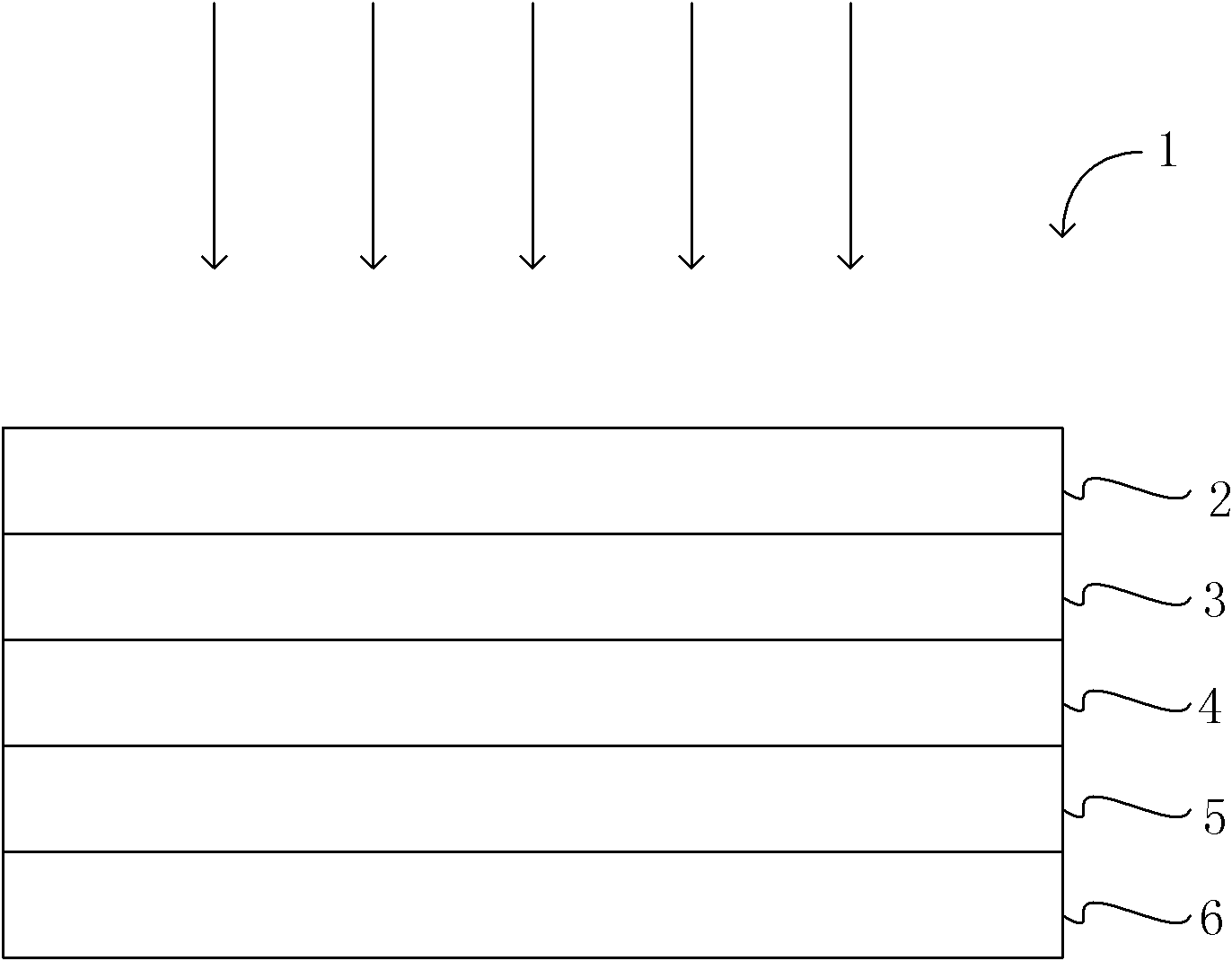

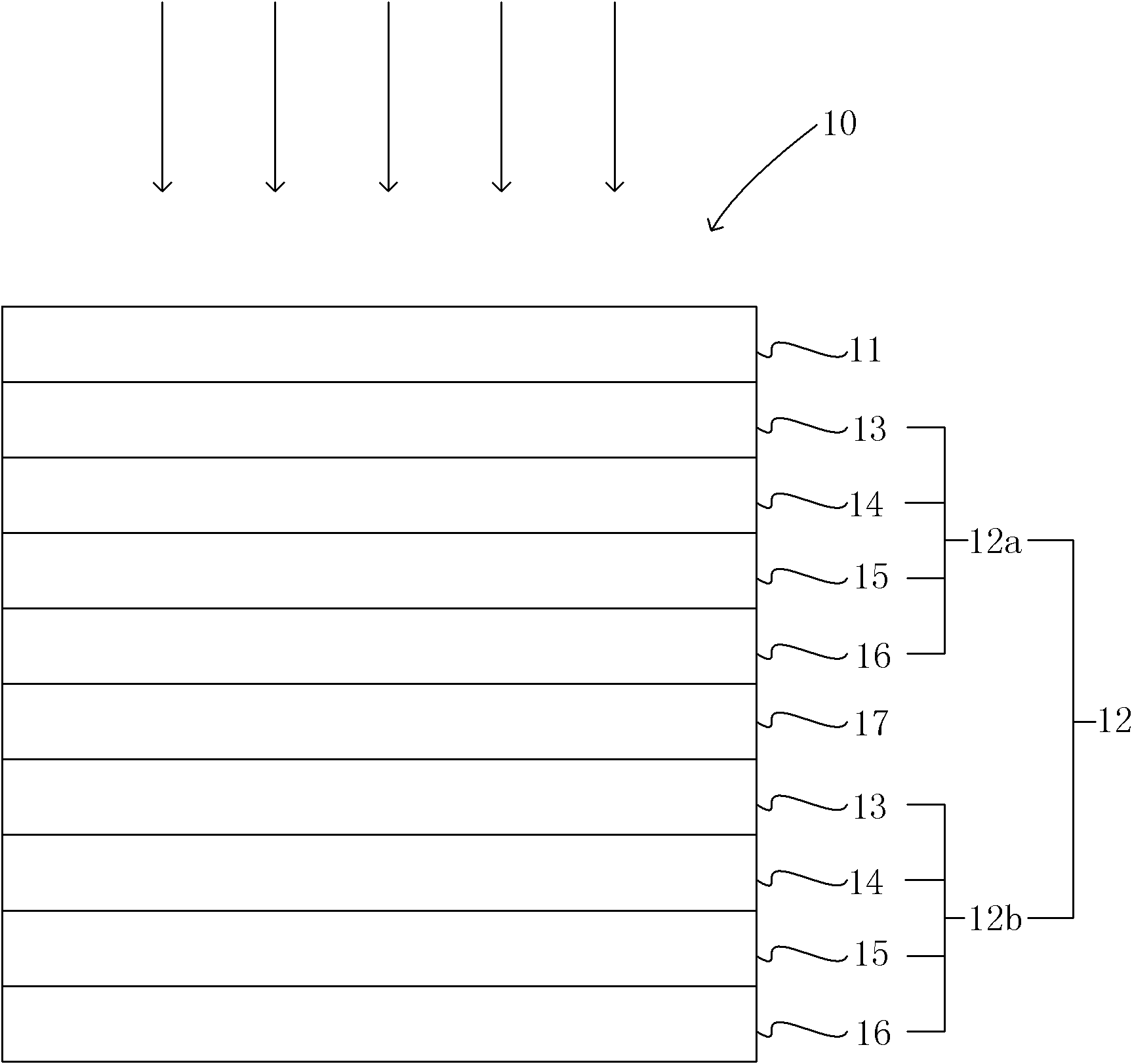

[0033] The problem to be solved by the present invention is to provide a solar cell group and its manufacturing method. The absorption layers of each solar cell in the solar cell group can maximize the photoelectric conversion efficiency without causing current mismatch or lattice mismatch. .

[0034] In order to solve the above problems, the present invention arranges a light-transmitting adhesive material layer between adjacent solar cells of the solar cell group, and the light-transmitting adhesive material layer insulates the two solar cells bonded by it from each other, so that the solar cells are independent of each other ( Independence here means that there can be no electrical conduction between two adjacent solar cells, that is, each solar cell has a separate circuit to export the electricity generated by itself), and there will be no current mismatch between the absorption layers of adjacent solar cells Or the problem of lattice mismatch; the light-transmitting adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com