A continuous flow hydrogenation reaction device, a selective reduction method for unsaturated aldehydes and ketones

A hydrogenation reaction and unsaturated technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reduced product yield and inability to separate products in time, so as to achieve a small footprint, improve utilization, and increase output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

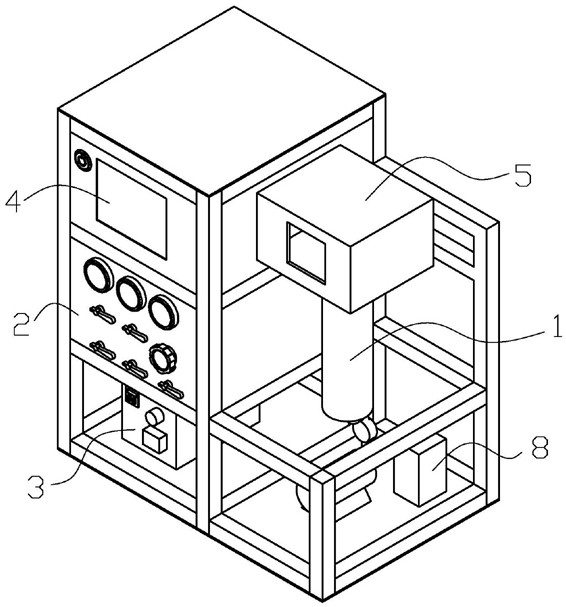

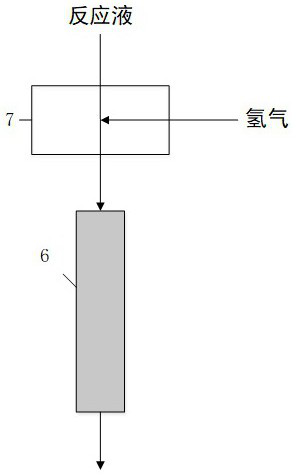

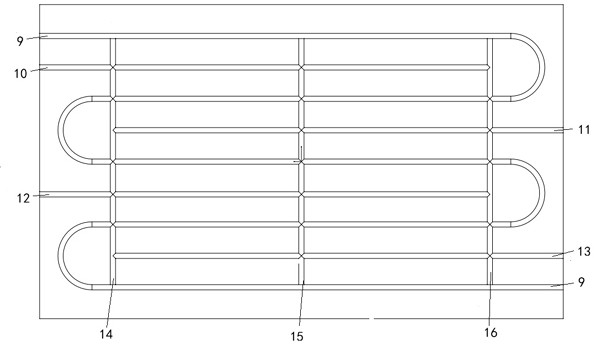

[0032] A continuous flow hydrogenation reactor, such as figure 1 As shown, it includes a reactor 1, a gas path control box 2, a liquid path control box 3, a preheating box 5 and an electrical control box 4. The top of the reactor 1 is provided with a gas path inlet and a liquid path inlet respectively, and the reactor 1 The bottom end is provided with a material outlet, and a catalyst bed is provided in the reactor; the gas path control box 2 is connected to the reactor 1 through the gas path inlet, and the liquid path control box 3 is connected to the reactor 1 through the gas path inlet. The inlet of the liquid path is communicated with the reactor pipe 1, the preheating box 5 is arranged at the inlet end of the reactor 1, the gas path control box 2, the liquid path control box 3 and the preheating box 5 are respectively connected with The electrical control box 4 is electrically connected, the parameter setting of the gas circuit control box 2, the liquid circuit control bo...

Embodiment 2

[0038] A selective reduction method for unsaturated aldehydes and ketones, based on the above-mentioned continuous flow hydrogenation reaction device, comprising: the flow rate of the hydrogen gas is controlled by the gas path control box, the flow rate of the hydrogen gas is controlled to be 100 SCCM, and the hydrogen gas is sent through the inlet of the gas path into the mixer;

[0039] The flow rate of the unsaturated aldehydes and ketones is controlled by the liquid path control box, and the flow rate of the unsaturated aldehydes and ketones is controlled to be 2mL / min, and is sent into the mixer through the inlet of the liquid path. The mass of the unsaturated aldehydes and ketones The concentration is 20%, and the solvent of unsaturated aldehydes and ketones is methanol;

[0040] The hydrogen and unsaturated aldehydes and ketones are mixed in the mixer and then enter the reaction tube. The volume of the reaction tube is 20mL, and flow through the catalyst bed. The cataly...

Embodiment 3

[0042] A selective reduction method for unsaturated aldehydes and ketones, based on the above-mentioned continuous flow hydrogenation reaction device, comprising: the flow rate of the hydrogen gas is controlled by the gas path control box, the flow rate of the hydrogen gas is controlled to be 10 SCCM, and the hydrogen gas is sent through the inlet of the gas path into the mixer;

[0043] The flow rate of the unsaturated aldehydes and ketones is controlled by the liquid circuit control box, and the flow rate of the unsaturated aldehydes and ketones is controlled to be 0.5mL / min, and is sent into the mixer through the inlet of the liquid circuit. The mass concentration is 5%, and the solvent is isopropanol;

[0044] The hydrogen and unsaturated aldehydes and ketones are mixed in the mixer and then enter the reaction tube. The volume of the reaction tube is 5mL, and flow through the catalyst bed. The catalyst bed height is 30cm. The mixture is separated to obtain a reduction pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com