Mass transfer tray and distillation column

A technology of mass transfer tower and distillation tower, which is applied in the field of chemical equipment, can solve the problems of liquid leakage, uneven distribution of gas phase, large bubble diameter, etc., and achieve the effect of not easy to coalesce, increase the area of mass transfer phase boundary, and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

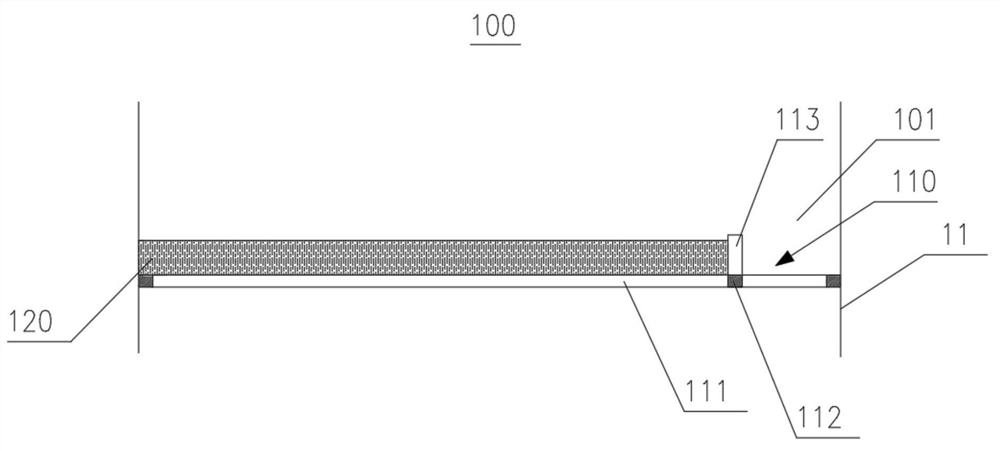

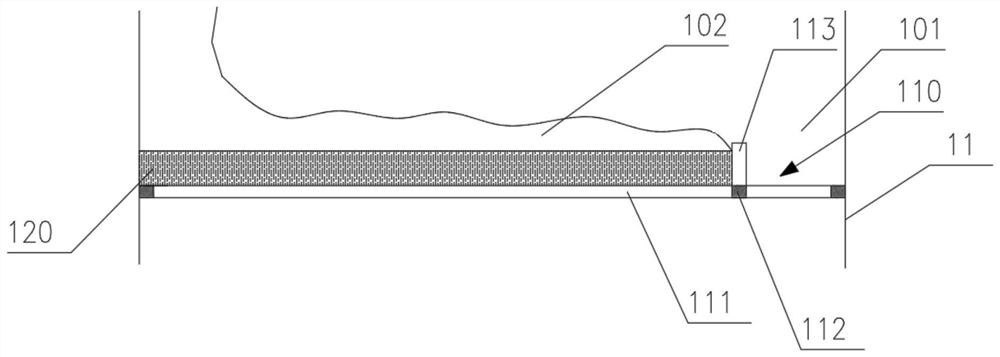

[0047] Please refer to figure 1 , this embodiment provides a mass transfer tray 100, including a gas-liquid mass transfer layer 120 and a tray support mechanism 110 for installing the mass transfer tray 100 in a distillation column, and the gas-liquid mass transfer layer 120 is arranged on On the tray support mechanism 110, the mass transfer tray 100 is installed behind the distillation tower, and there is a gap for the liquid to descend between one end edge of the gas-liquid mass transfer layer 120 and the tower wall 11 of the distillation tower.

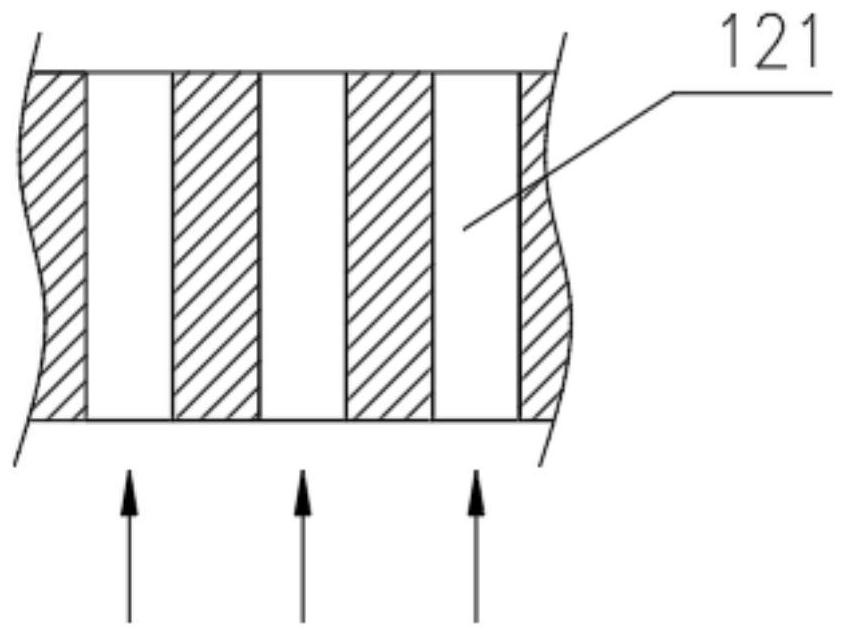

[0048] The pores 121 on the gas-liquid mass transfer layer 120 for dispersing gas have a diameter of 0.1-100 μm, and the porosity of the gas-liquid mass transfer layer 120 is 1%-80%.

[0049] During use, the tray supporting mechanism 110 is arranged on the tower wall 11 of the distillation tower, so that a gap (downhole 101) for the liquid to descend is formed between one end edge of the gas-liquid mass transfer layer 120 and the t...

no. 2 example

[0058] This embodiment is basically similar to the first embodiment, and the unmentioned parts refer to the first embodiment.

[0059] Such as Figure 5 As shown, the gas-liquid mass transfer layer 120 of the mass transfer tray 100 of this embodiment is made by sintering, and the pores 121 contained therein are also formed during the sintering process.

[0060] It should be noted that, in other embodiments of the present application, the gas-liquid mass transfer layer 120 can also be made by 3D printing or a combination of sintering and 3D printing.

[0061] Specifically, the material of the gas-liquid mass transfer layer 120 is metal, metal oxide, plastic, resin, ceramics, graphite, corundum or a mixture of at least two of the above materials.

[0062] Preferably, the upper surface of the gas-liquid mass transfer layer 120 is coated with a super-lyophobic coating. The super-oleophobic coating is, for example, a super-hydrophobic coating or a super-oleophobic coating, and th...

application example 1

[0082]The tray provided in the first embodiment is used. The pores 121 of the gas-liquid mass transfer layer 120 are uniformly arranged cylindrical channels with an opening ratio of 60%, a pore diameter of 100 μm, and a thickness of the mass transfer material of 5 mm. Through the cyclohexane-n-heptane system test, the efficiency of the microbubble tray is about 62% higher than that of the F1 valve tray, and about 16% higher than that of the microbubble overall tray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com