Nylon melon petal combined nesting sleeve for small aluminum strip splitting machine

A technology of slitting machine and aluminum strip, which is applied in the field of nesting of nylon melon petals, which can solve the problems of fixed diameter of cone head, easy unwinding and staggered layers, difficulty in rolling up and bottom winding, and achieves the effect of not being easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

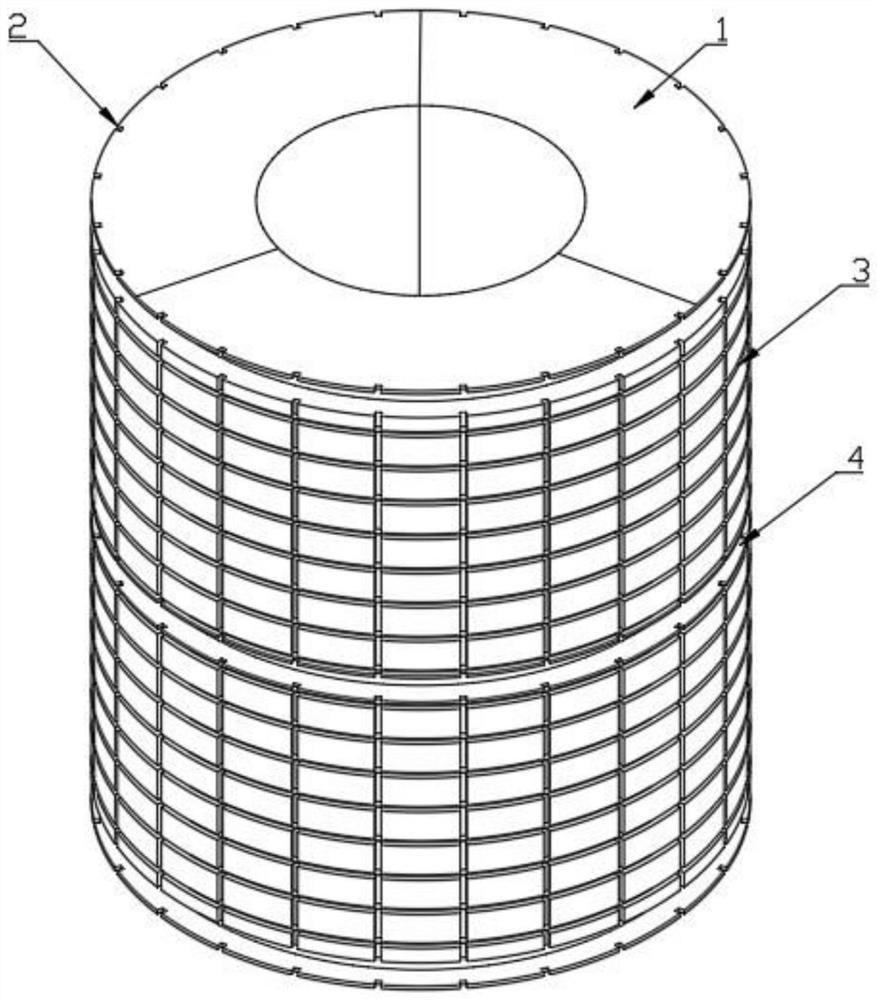

[0016] Such as figure 1 As shown, a small-sized aluminum strip slitting machine is nested with nylon melon petals, including a fan-shaped cylinder 1, a longitudinal groove 2, a transverse groove 3 and an annular clamping groove 4.

[0017] A small aluminum strip slitting machine is nested with nylon melon petals, including three fan-shaped cylinders with the same shape and equal size. The angle formed by the two sides of the fan-shaped cylinder is 120°, and the three fan-shaped cylinders are combined to form A complete cylinder, the center of the cylinder is provided with a through hole whose size matches the cone on the slitting machine, the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com