A kind of polypropylene controllable rheology modifier and preparation method thereof

A rheology modifier, polypropylene technology, applied in the direction of one-component polyolefin rayon, rayon manufacturing, textile and papermaking, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In one embodiment of the present application, a preparation method of a polypropylene controllable rheology modifier is provided, comprising:

[0030] The polypropylene controllable rheology modifier base material is prepared, and the polypropylene controllable rheology modifier base material is put into a high-speed mixer for dry mixing. In this application, the time of the dry mixing process is 15min-30min ;

[0031] The mixed polypropylene controllable rheology modifier premix is placed in a twin-screw granulator for melt extrusion and granulation to obtain a polypropylene controllable rheology modifier. The rotation speed of the screw in the pellet mill is 360r / min-600r / min, and the specific process of melt extrusion is: the temperature of the first stage to the second stage is 225°C-235°C, the temperature of the third stage to the fifth stage is 235°C-245°C, and the temperature of the sixth stage is 235°C-245°C. The temperature is 215°C-225°C, the temperature of...

Embodiment 1

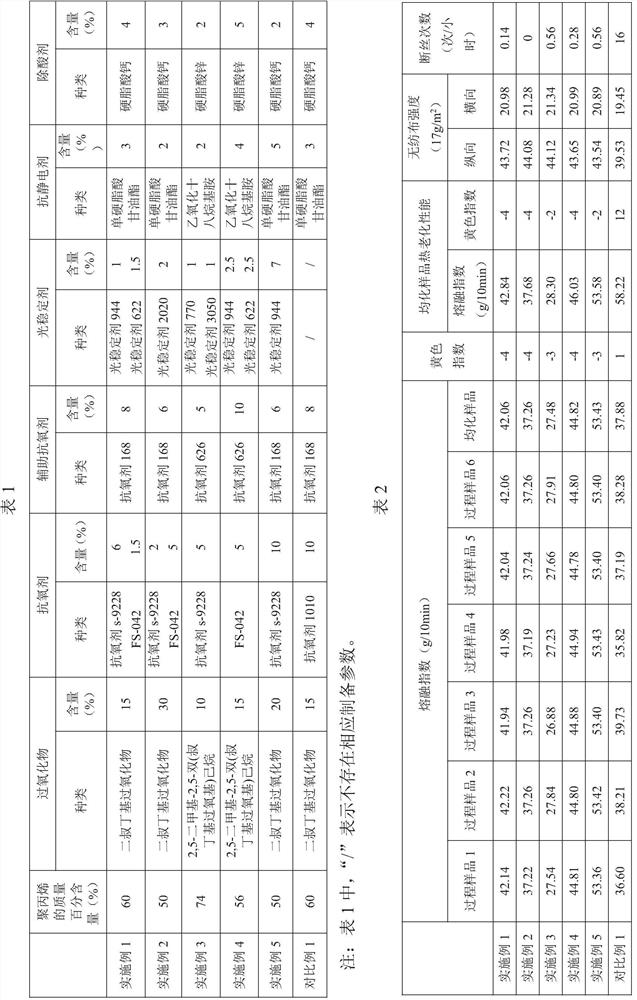

[0044]

[0045] The polypropylene controlled rheology modifier base material contains the following components by mass percentage: polypropylene 60%, di-tert-butyl peroxide 15%, antioxidant s-9228 6%, FS-042 1.5% , light stabilizer 944 1%, light stabilizer 6221.5%, auxiliary antioxidant 168 8%, glycerol monostearate 3%, calcium stearate 4%.

[0046]

[0047] Put the weighed polypropylene controllable rheology modifier base material into a high-speed mixer, and dry-mix at 25°C for 20 minutes.

[0048]

[0049] Put the mixed polypropylene controllable rheology modifier premix into a twin-screw granulator with a screw length-to-diameter ratio of 42 and a screw speed of 580 r / min, melt extrusion, and pelletize to obtain controllable polypropylene. Rheology modifier, wherein, the specific process parameters of melt extrusion include: the temperature of the first stage to the second stage is 230 ° C, the temperature of the third stage to the fifth stage is 240 ° C, the tempera...

Embodiment 2

[0057] In addition to adjusting the composition and mass percentage of polypropylene controllable rheology modifier base material according to Table 1, in the process of , 0.3% of the above-mentioned polypropylene powder was added to 2000kg of polypropylene powder. Except for the polypropylene controllable rheology modifier, the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com