Nanometer piezoelectric fiber film material and preparation method and application thereof

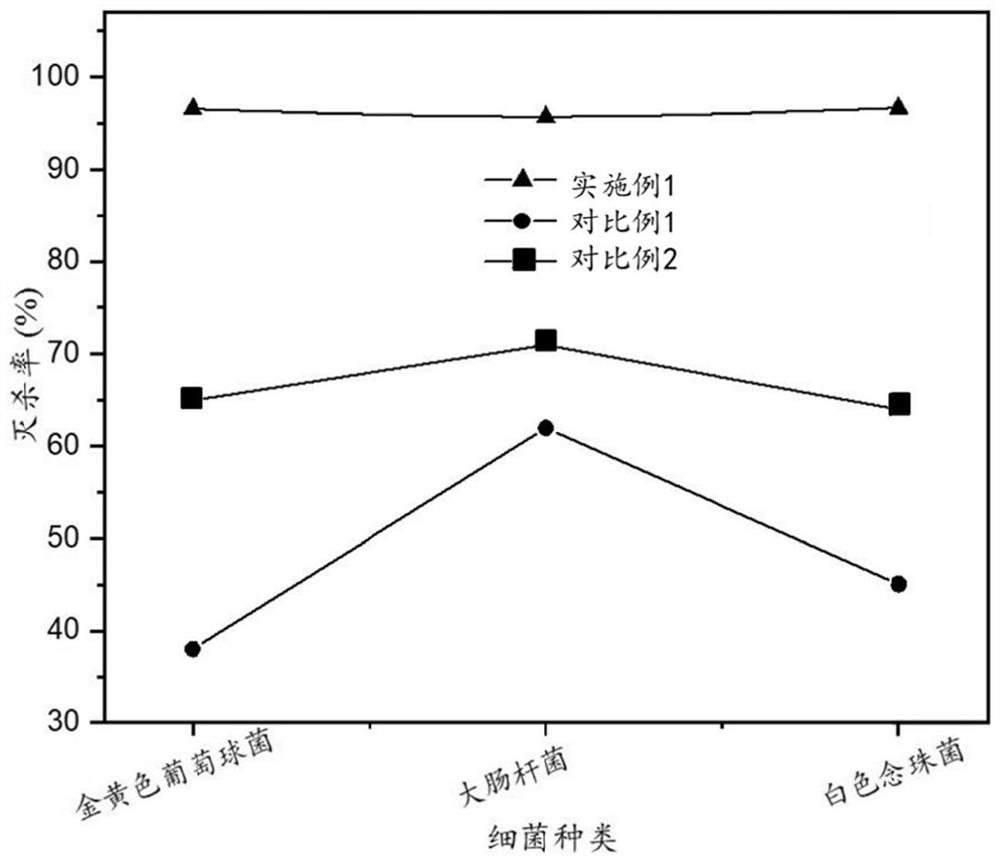

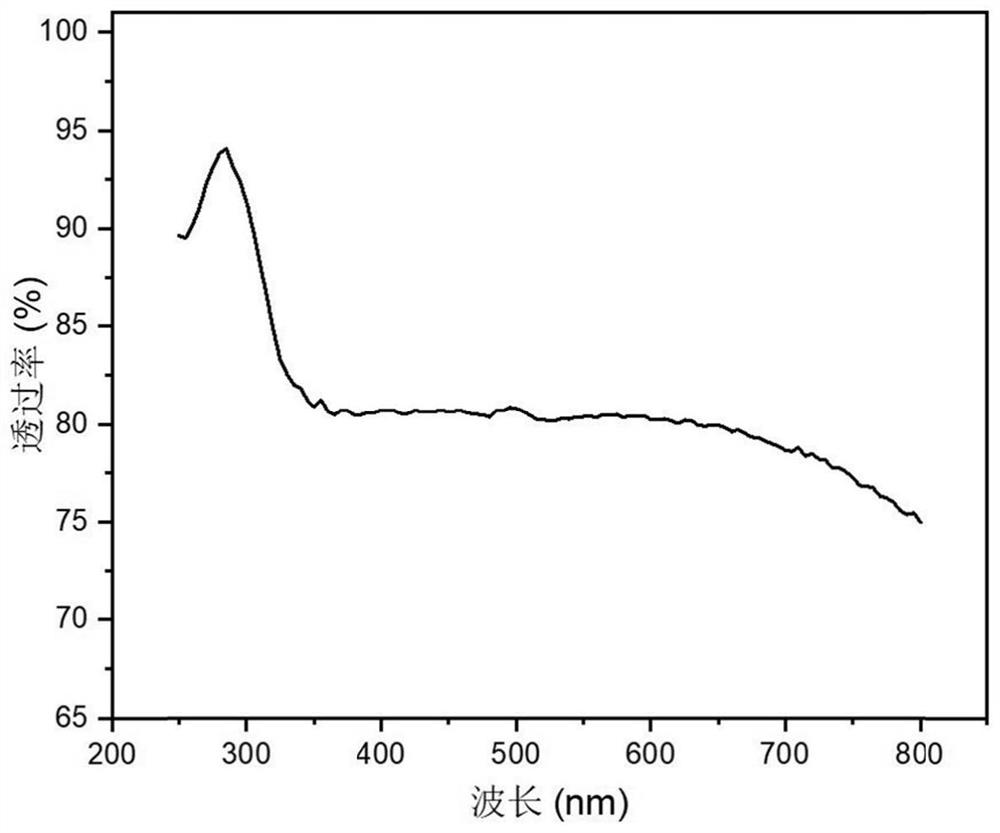

A piezoelectric fiber and film material technology, which is applied in the field of nano piezoelectric fiber film materials and its preparation, can solve problems such as unsatisfactory sterilization effects, and achieve the effects of improving piezoelectric sterilization performance, high flexibility, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

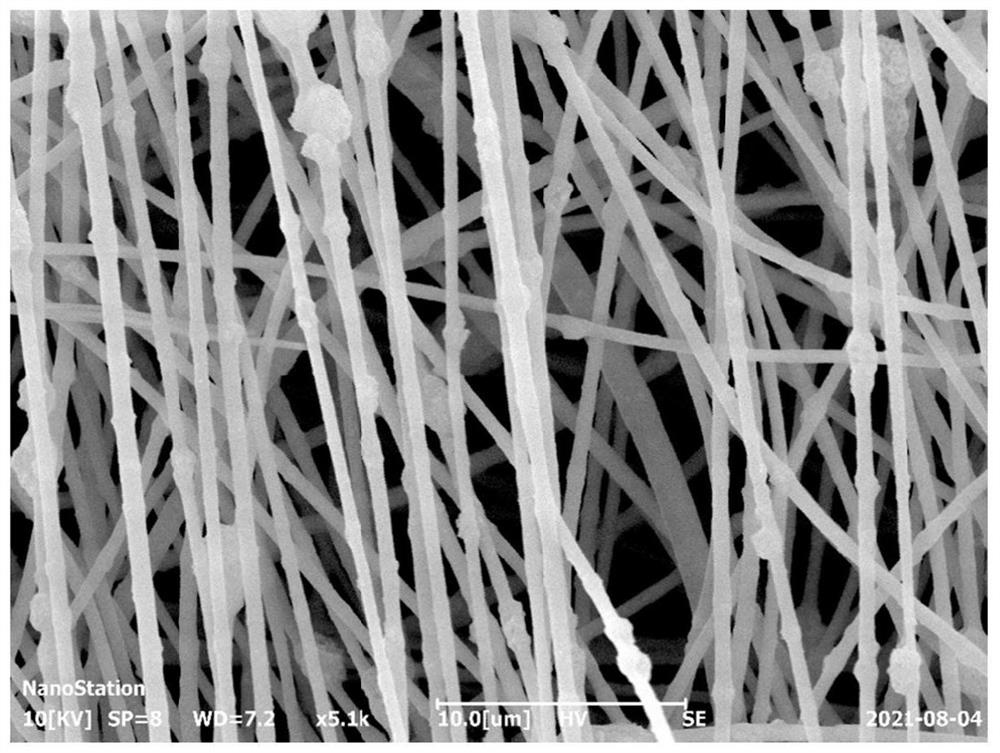

[0043] This embodiment provides a nano piezoelectric fiber film, the preparation raw materials of the nano piezoelectric fiber film include: 43 parts by mass of vinylidene cyanide, 47.5 parts by mass of vinyl acetate, 3.5 parts by mass of benzoyl peroxide, 6 Parts by mass of MoSe 2 . The preparation method of this nano piezoelectric fiber film is as follows:

[0044] (1) Vinylidene cyanide, vinyl acetate and MoSe 2 Dry at 70°C for 24h.

[0045] (2) Dissolve the dried vinylidene cyanide and vinyl acetate in 50mL of benzene solution respectively, mix the solutions, add benzoyl peroxide dropwise as an initiator, and keep warm in a water bath at 45°C for 2 hours to obtain Vinyl cyanide / vinyl acetate) precipitation.

[0046] (3) Wash the precipitate with distilled benzene, then dissolve the solid in dimethylformamide solution, and finally add the benzene solution to precipitate the precipitate to obtain a white solid.

[0047] (4) Dissolve the obtained white solid in 10 mL of ...

Embodiment 2

[0056] This embodiment provides a nano piezoelectric fiber film, the preparation raw materials of the nano piezoelectric fiber film include: 44 parts by mass of vinylidene cyanide, 48 parts by mass of vinyl acetate, 2 parts by mass of benzoyl peroxide, 6 Parts by mass of MoS 2 . The preparation method of this nano piezoelectric fiber film is as follows:

[0057] (1) Combine vinylidene cyanide, vinyl acetate and MoS 2 Dry at 70°C for 24h.

[0058] (2) Dissolve the dried vinylidene cyanide and vinyl acetate in 50mL of benzene solution respectively, mix the solutions, add benzoyl peroxide dropwise as an initiator, and keep warm in a water bath at 45°C for 2 hours to obtain Vinyl cyanide / vinyl acetate) precipitation.

[0059] (3) Wash the precipitate with distilled benzene, then dissolve the solid in dimethyl sulfoxide solution, and finally add benzene solution to precipitate the precipitate to obtain a white solid.

[0060] (4) Dissolve the obtained white solid in 10 mL of d...

Embodiment 3

[0064] This embodiment provides a nano piezoelectric fiber film, the preparation raw materials of the nano piezoelectric fiber film include: 44 parts by mass of vinylidene cyanide, 48 parts by mass of vinyl acetate, 2 parts by mass of benzoyl peroxide, 6 In parts by mass 2 Se 3 . The preparation method of this nano piezoelectric fiber film is as follows:

[0065] (1) Vinylidene cyanide, vinyl acetate and In 2 Se 3 Dry at 70°C for 24h.

[0066] (2) Dissolve the dried vinylidene cyanide and vinyl acetate in 50mL of benzene solution respectively, mix the solutions, add benzoyl peroxide dropwise as an initiator, and keep warm in a water bath at 45°C for 2 hours to obtain Vinyl cyanide / vinyl acetate) precipitation.

[0067] (3) Wash the precipitate with distilled benzene, then dissolve the solid in dimethylformamide solution, and finally add the benzene solution to precipitate the precipitate to obtain a white solid.

[0068] (4) The obtained white solid was dissolved in 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap