Acid digital printing pretreatment agent and preparation method thereof

A pre-treatment agent, digital printing technology, applied in the direction of dyeing, textile and papermaking, etc., can solve the problems of insufficient printing depth, clarity and fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

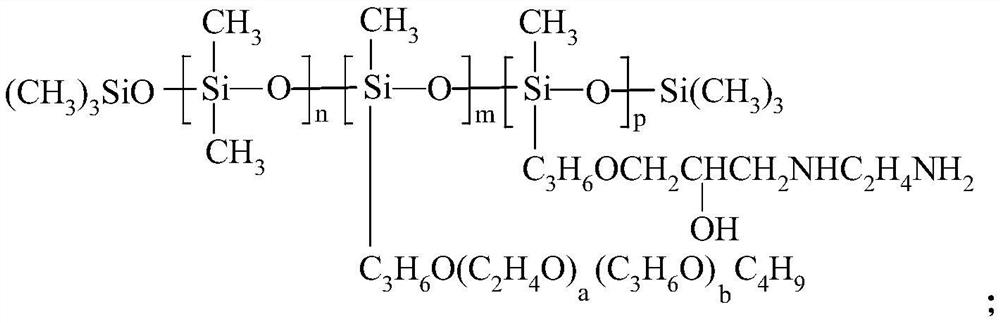

Method used

Image

Examples

Embodiment 1

[0051] The formula of acidic digital printing pretreatment agent in the present embodiment is as follows:

[0052]

[0053] The present invention provides a kind of preparation method of above-mentioned acid digital printing pretreatment agent, it comprises:

[0054] 1) The preparation method of modified cellulose 1

[0055] 2.45 parts by weight of hydroxyethyl cellulose (DS.=1.0) and 2.45 parts by weight of carboxymethyl cellulose (DS.=1.1) were mixed and dispersed at a concentration of 50 parts by weight 70wt.% ethanol solution, adding 2.45 parts by weight of NaOH solution with a concentration of 0.07wt.%, alkalized at room temperature for 30min, and adding 0.1g part of epichlorohydrin dropwise, The temperature was raised to 50°C for etherification reaction for 3h. The reacted products were washed with absolute ethanol and filtered three times, and dried in an oven at 50° C. for 24 hours to obtain 5 parts by weight of modified cellulose 1 .

[0056] 2) The preparation ...

Embodiment 2

[0063] The formula of acidic digital printing pretreatment agent in the present embodiment is as follows:

[0064]

[0065] The present invention provides a kind of preparation method of above-mentioned acid digital pretreatment agent, it comprises:

[0066] 1) The preparation method of modified cellulose 2

[0067] 4.9 parts by weight of hydroxyethyl cellulose (DS.=1.5) and 4.9 parts by weight of carboxymethyl cellulose (DS.=1.8) were mixed and dispersed at a concentration of 100 parts by weight 70wt.% ethanol solution, adding 4.9 parts by weight of NaOH solution with a concentration of 0.07wt.%, alkalized at room temperature for 30min, and adding 0.2g parts by weight of epichlorohydrin dropwise, The temperature was raised to 50°C for etherification reaction for 3h. The reacted products were washed with absolute ethanol and filtered three times, and dried in an oven at 50° C. for 24 hours to obtain 10 parts by weight of modified cellulose 2 .

[0068] 2) The preparation...

Embodiment 3

[0075] The formula of acidic digital printing pretreatment agent in the present embodiment is as follows:

[0076]

[0077] The invention provides a kind of preparation method of above-mentioned acid digital pretreatment agent, it comprises:

[0078] 1) Preparation method of modified cellulose 3

[0079]3.43 parts by weight of hydroxyethyl cellulose (DS.=1.5) and 3.43 parts by weight of carboxymethyl cellulose (DS.=1.5) were mixed and dispersed at a concentration of 70 parts by weight 70wt.% ethanol solution, adding 3.43 parts by weight of NaOH solution with a concentration of 0.07wt.%, alkalized at room temperature for 30min, adding 0.14g parts of epichlorohydrin dropwise, The temperature was raised to 50°C for etherification reaction for 3h. The reacted products were washed with absolute ethanol and filtered three times, and dried in an oven at 50° C. for 24 hours to obtain 7 parts by weight of modified cellulose 3 .

[0080] 2) The preparation method of modified carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com