Sampling detection equipment for controlling uniform dispersion of nano-powder

A technology of uniform dispersion and sampling detection, applied in solid separation, preparation of test samples, sampling, etc., can solve problems such as low referentiality and difficulty in obtaining samples, and achieve the effect of avoiding coagulation and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

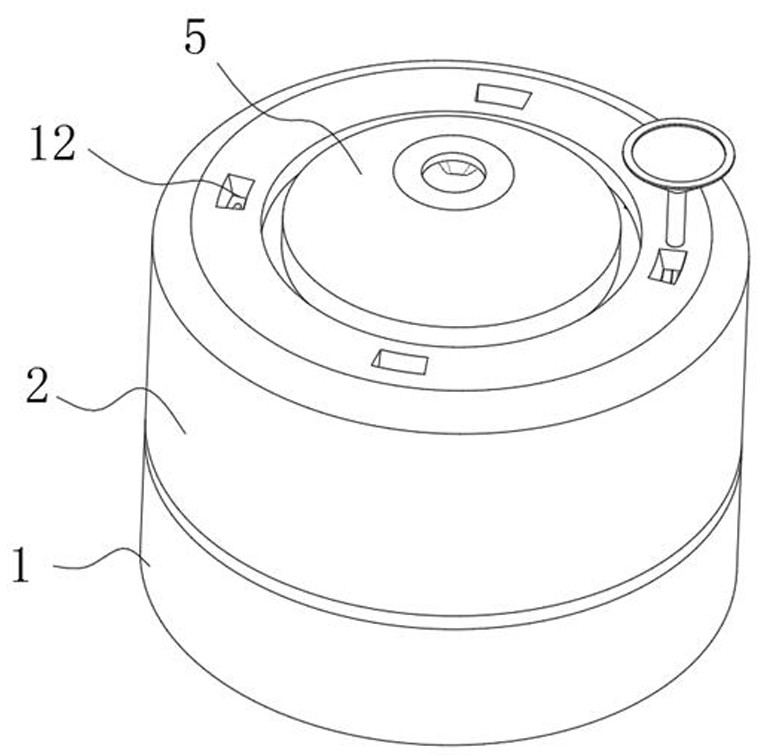

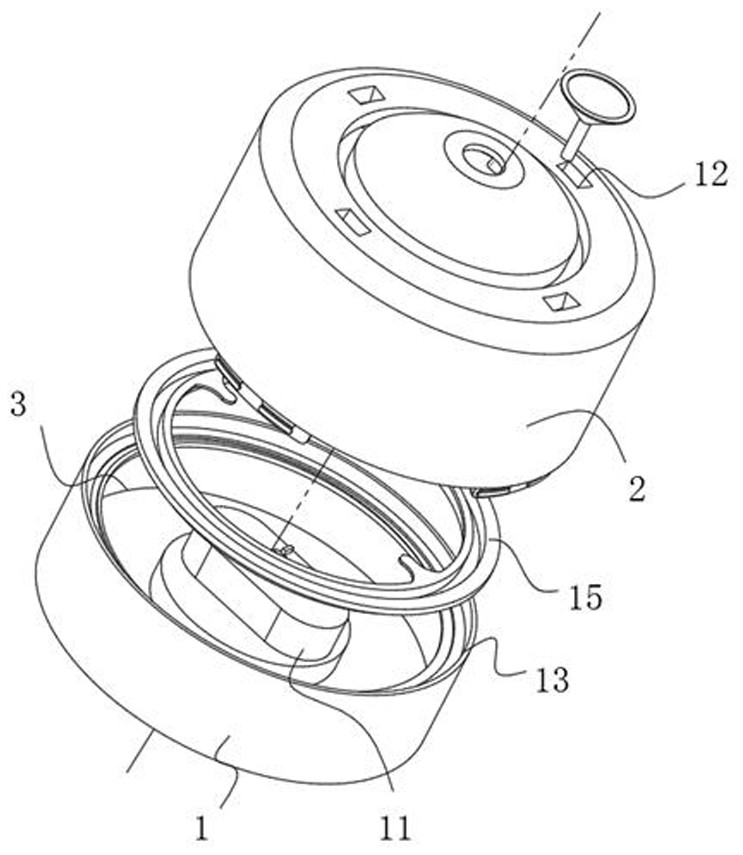

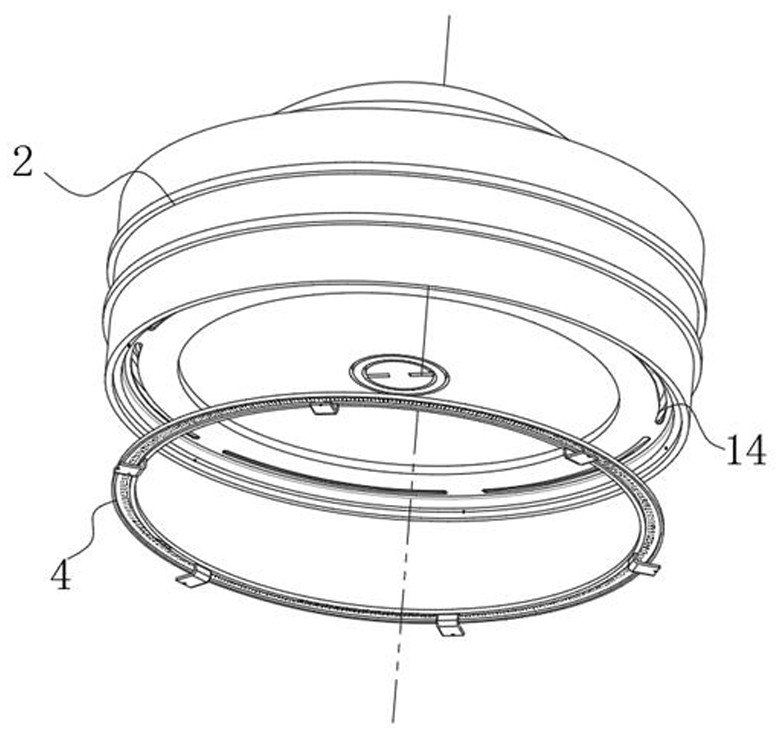

[0038] Example: refer to Figure 1-10 , a sampling and testing device for controlling the uniform dispersion of nano powders, including a circular base 1, a motor 11 is installed in the middle of the inner side of the base 1 in this example, and the upper end of the base 1 is threadedly fitted with the shell 2 located on the upper part of the base 1 , and the housing 2 is provided with a rotatable friction device 21, the bottom of the friction device 21 is provided with two teeth slots, and the output end of the motor 11 is connected with a bayonet corresponding to the slots at the bottom of the friction device 21, during actual use The use of the motor 11 in this example is not limited, and other driving structures can also be used instead. The screening process in this example requires a lower rotational speed of 50-80 rpm, and the centrifugal force produced is not enough to throw the friction device 21. out.

[0039] The upper part of the casing 2 is provided with four fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com