Plate washing machine integrating plate drying and sterilizing functions

A plate washer and plate drying technology, which is applied in the field of medical equipment and can solve the problems such as the inability to completely recover the residual liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

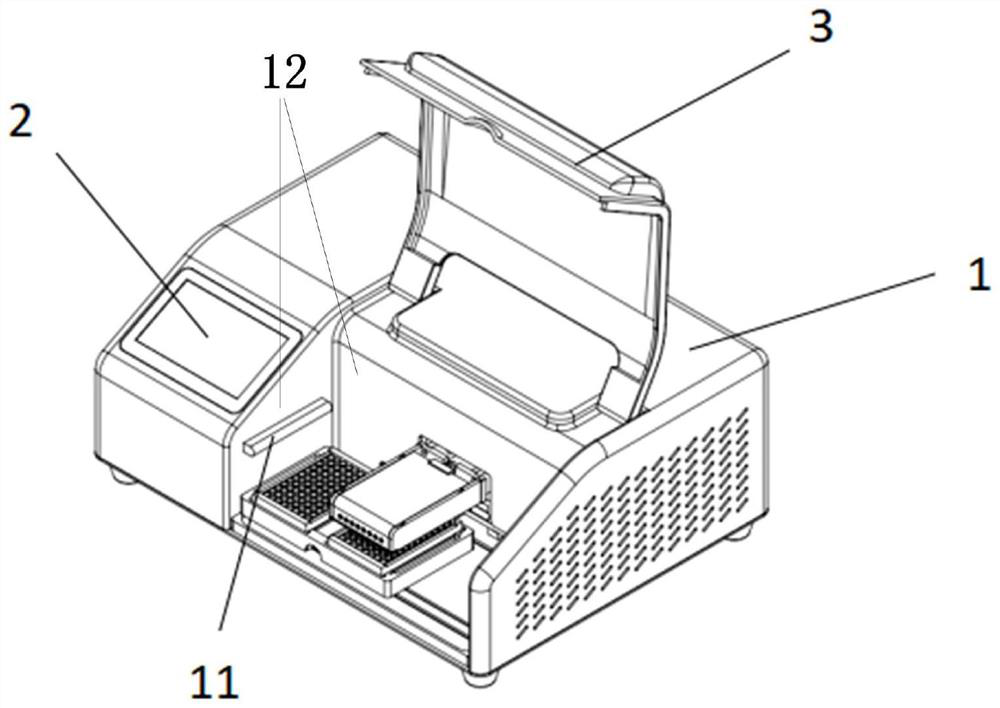

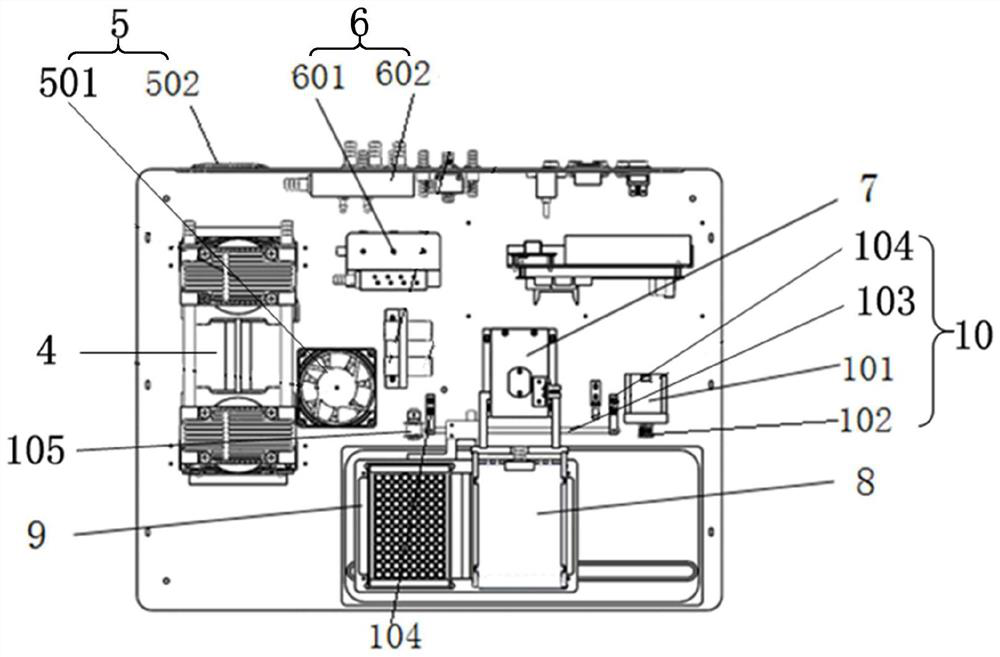

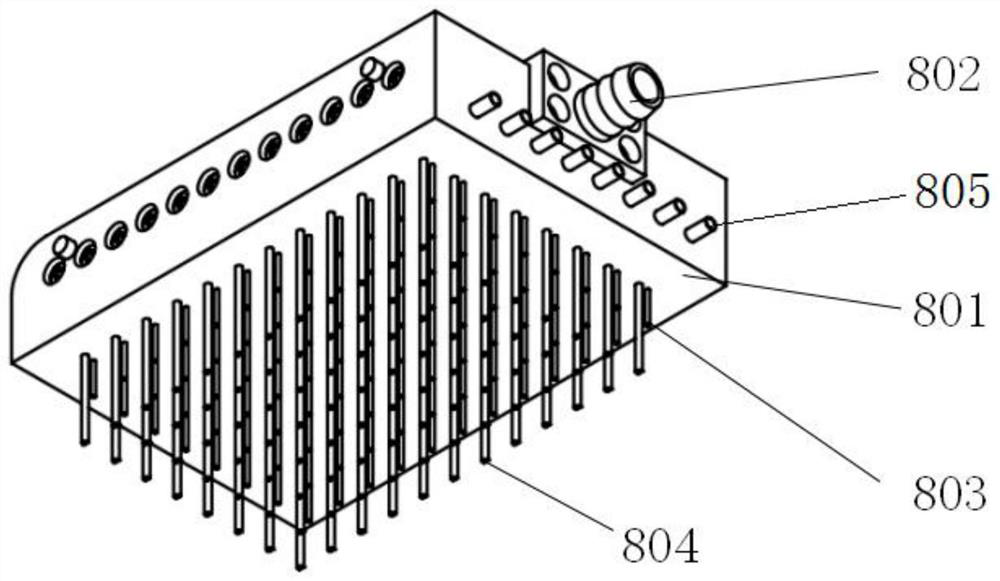

[0038] Such as figure 2As shown, a plate washing machine with an integrated baking plate sterilization function includes: a casing 1, which is divided into an electric control installation area, a mechanism installation area and an operation area with a control system installed by a partition 12 in the casing 1, and the mechanism installation area The area is equipped with a suction device 4 electrically connected to the control system, an air-cooled heat dissipation system 5, a washing liquid separation system 6, and a reciprocating device 7 for suction and injection liquid. The operating area is equipped with a plate washing head 8 and a baking plate electrically connected to the control system. Device 9 and ster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com