A dual-station reaming tool for an automobile chassis bushing

An automobile chassis and double-station technology, which is applied in the direction of manufacturing tools, boring/drilling, metal processing equipment, etc., can solve the problems of waste of resources, difficulty in collection, splashing of debris, etc., and achieve easy recycling and safe removal , The effect of reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

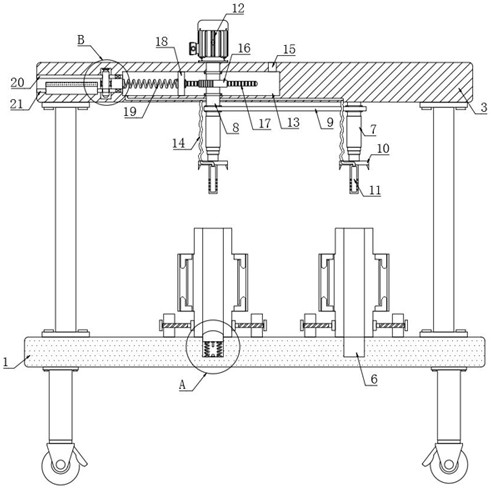

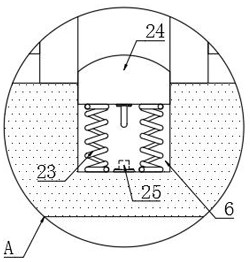

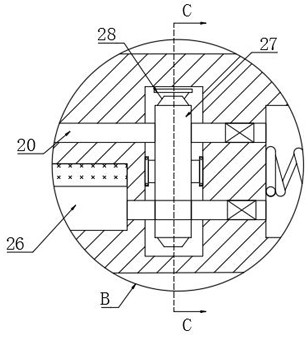

[0024] refer to Figure 1-4 , a dual-station reaming tool for an automobile chassis bushing, comprising a base 1, two support columns are arranged symmetrically above the base 1, a top plate 3 is fixedly connected to the top of the two support columns, and the lower end of the top plate 3 is rotatably connected There are two rotating rods 8, the lower ends of the two rotating rods 8 are fixedly connected to the electric telescopic rod 7, the telescopic ends of the two electric telescopic rods 7 are fixedly connected to the mounting plate 10, and the lower ends of the two mounting plates 10 are fixedly connected to the annular blade , the annular blade can be replaced according to actual needs, the two rotating rods 8 are connected through a transmission structure 9, the transmission structure 9 includes a transmission wheel arranged on the two rotating rods 8, and the two transmission wheels are connected through a transmission belt; the top plate 3 There is a moving chamber 1...

Embodiment 2

[0038] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that the lower end of the base 1 is provided with a collection box 30, and the collection box 30 is provided with a horizontal plate 4, and the horizontal plate 4 is slidably connected with the inner wall of the collection box 30, and the horizontal plate 4 The lower end and the inner bottom of the collection box 30 are elastically connected by two springs 31, and the top space of the collection box 30 is connected with a plurality of suction pipes, and the plurality of suction pipes run through the base 1, and the space on the right side of the moving chamber 13 is connected to the collection box. The bottom space of the box 30 is communicated through the connecting pipe 22, and the connecting pipe 22 and the port 15 are provided with a one-way valve. The gas in the space enters into the bottom space of the collection box 30 in one direction through the connecting pipe 22. The bottom space of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com