Magnesia refractory material storage barrel

A technology for refractory materials and storage barrels, applied in the field of refractory materials, can solve the problems of moisture in magnesia refractory materials, deterioration of refractory materials, easy deterioration, etc., and achieve the effect of improving practicability and reducing moisture exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

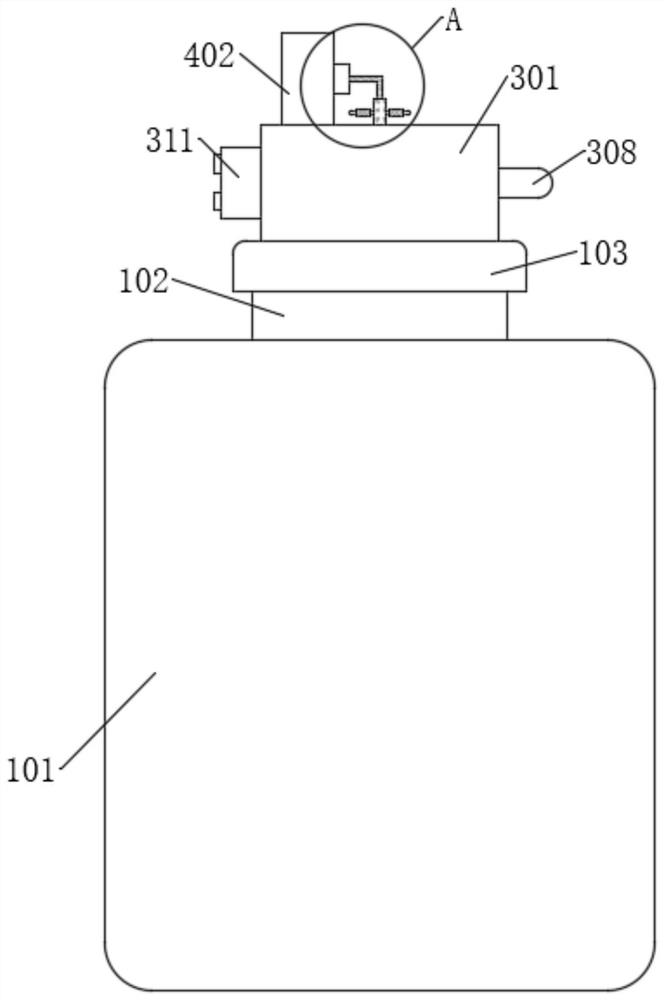

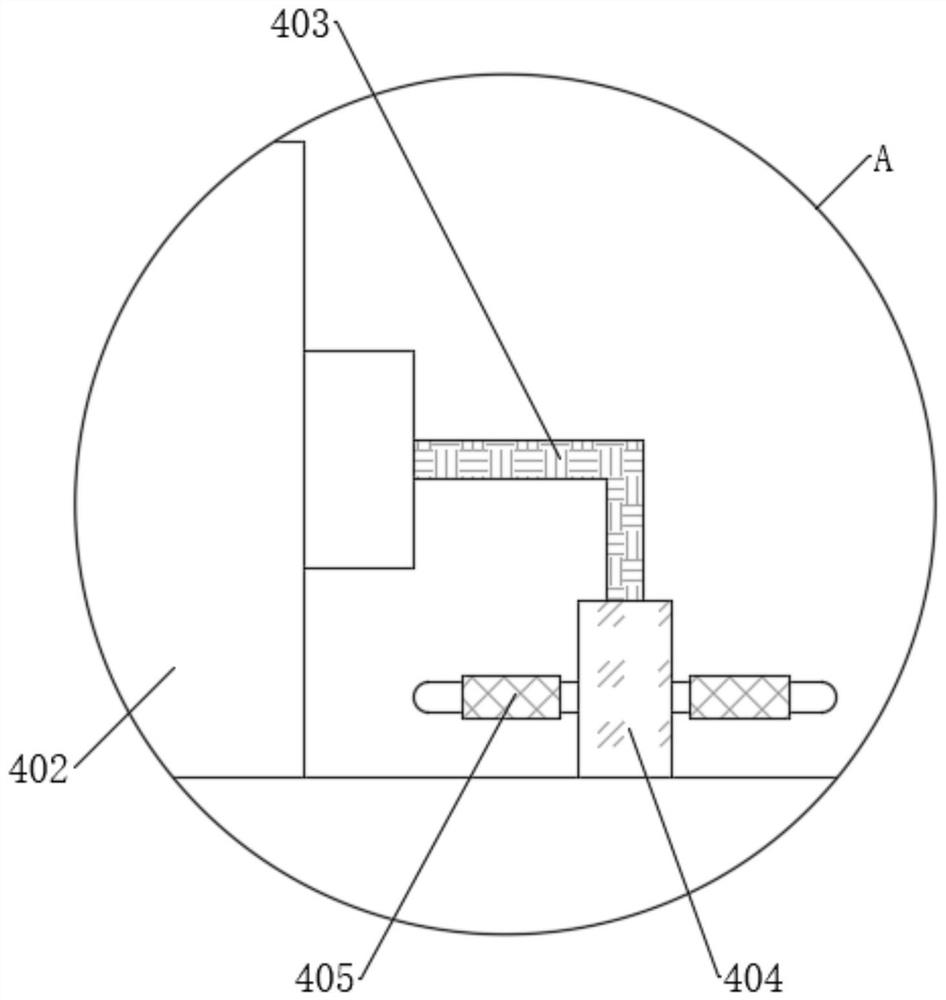

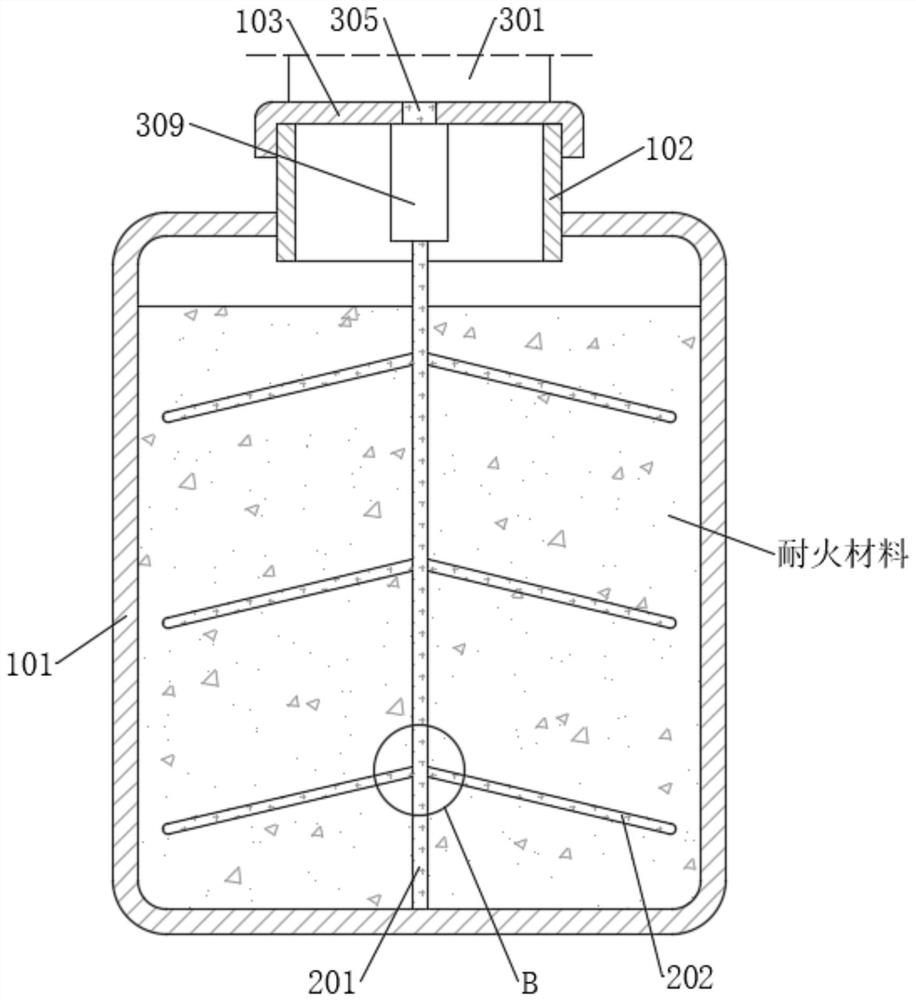

[0045] see Figure 1-10 , a magnesia refractory material storage barrel, including a barrel body 101, the top of the barrel body 101 is connected with an inlet and outlet pipe 102, and the top of the inlet and outlet pipe 102 is provided with a matching sealed barrel cover 103, the barrel body 101 A set of suction guide rods is arranged inside, and the suction guide rod set includes a main suction guide rod 201 fixedly installed on the inner wall of the bottom end of the barrel body 101, and a plurality of main heat support cores 203 are fixedly connected to both sides of the main suction guide rod 201, The main suction guide rod 201 is embedded with a main thermal support core 203, and the branch suction guide rod 202 is embedded with a branch heat conduction support core 204. One end of the branch heat conduction support core 204 runs through the branch suction guide rod 202 and extends to the main heat support. The core 203 is fixedly connected, and the bottom end of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com