Method for purifying aniline

A technology for aniline and crude aniline, which is applied in the fields of purification/separation of amino compounds, organic chemistry, etc., and can solve the problems of not considering the disposal process of low boilers, fluctuations in the operation process, and affecting product quality, and achieves short purification process and good reliability , The effect of comprehensive utilization of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The crude aniline from the aniline plant is produced at a temperature of 80 °C and a pressure of 0.3 MPa. The main components are shown in Table 1.

[0035] Table 1 crude aniline composition

[0036]

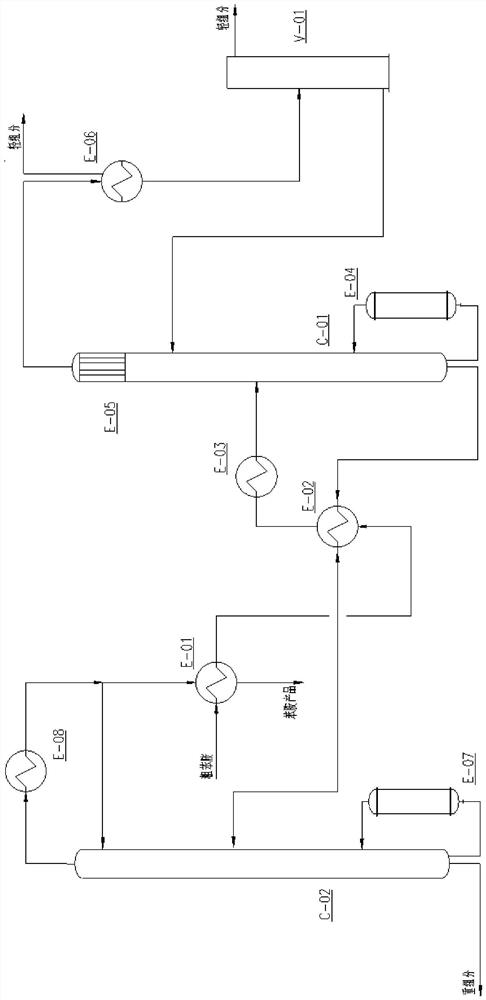

[0037] The treatment process is as follows: the flow rate of the above components is 6000kg / h. Crude aniline is first heated to 120°C through the aniline product heat exchanger E-01, the light column cooler E-02 and the preheater E-03, and then enters the light Tower C-01, control light tower C-01 tower top operating pressure is -0.075MPaG, tower bottom operating pressure is -0.069MpaG, through light tower reboiler E-04 control tower top and tower bottom operating temperature are 108 ℃ and 144°C; light tower C-01 overhead gas phase 1002kg / h is cooled to 65°C and 20°C respectively by tower top cooler E-05 and tower top condenser E-06, and 81kg of non-condensable gas in condenser E-06 / h (mainly 2.4kg of aniline, 23.7kg of water, 12kg of benzene, 42kg of cyclohexane, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com