Method for preparing fodder-grade calcium hydrogen phosphate or fodder-grade calcium hydrogen phosphate type III

A technology of calcium dihydrogen phosphate and calcium hydrogen phosphate, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of restricting the development of feed-grade calcium phosphate salt, environmental pressure, and long production process. Achieve the effects of high yield, low production cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

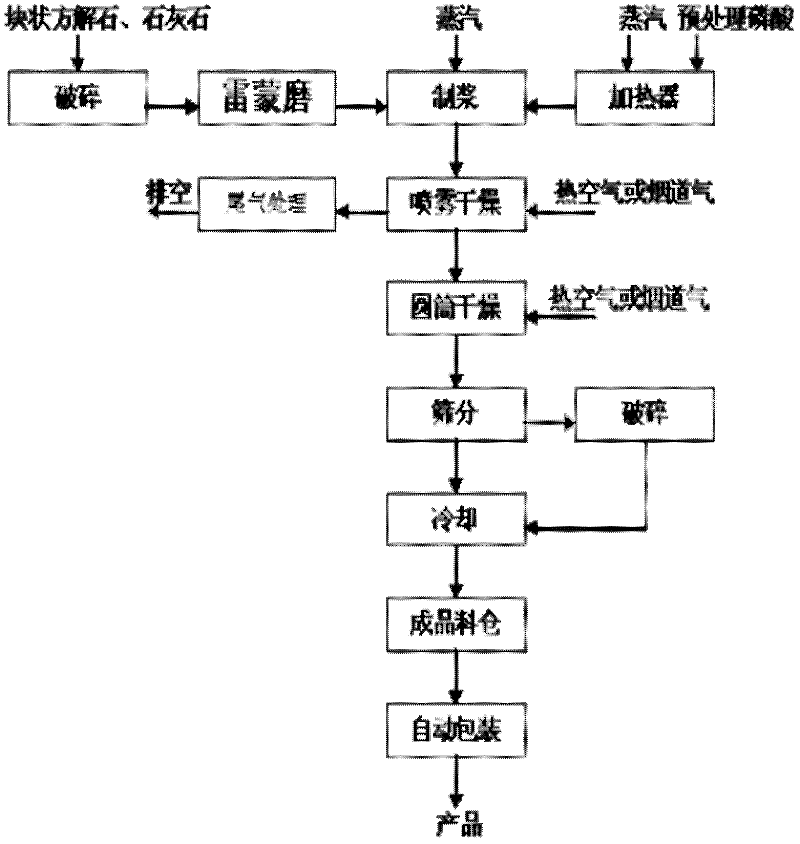

[0033] Embodiment 1 adopts the inventive method to produce powdery feed grade calcium dihydrogen phosphate

[0034] The method proceeds as follows:

[0035] 1. Heating of pretreated phosphoric acid and neutralization of calcium powder to make pulp;

[0036] 2. Spraying and secondary drying of slurry;

[0037] 3. Screening and crushing of powdery materials, cooling and packaging of finished products.

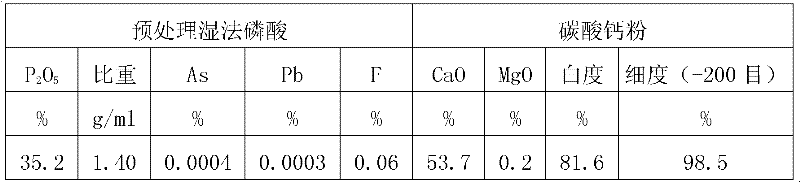

[0038] The quality indicators of pretreated phosphoric acid and heavy calcium (calcium carbonate) powder are shown in Table 1.

[0039] The quality of table 1 pretreatment phosphoric acid and heavy calcium (calcium carbonate) powder

[0040]

[0041] 1. Heating of pretreated phosphoric acid and neutralization of calcium powder to make pulp

[0042] ① Pretreatment wet process phosphoric acid comes from phosphoric acid storage tank, P 2 o5 Concentration 35.2% (mass concentration, the same below), specific gravity 1.40g / ml, temperature 40°C; at 27.9m 3 The flow rate per hou...

Embodiment 2

[0052] [0052] Embodiment 2 adopts the inventive method to produce powdery feed grade calcium hydrogen phosphate III type

[0053] Follow these steps:

[0054] 1. Heating of pretreated phosphoric acid and neutralization of calcium powder to make pulp;

[0055] 2. Spraying and secondary drying of slurry;

[0056] 3. Screening and crushing of powdery materials, cooling and packaging of finished products.

[0057] The quality indicators of pretreated phosphoric acid and heavy calcium (calcium carbonate) powder are shown in Table 3.

[0058] The quality index of table 3 pretreatment phosphoric acid and heavy calcium (calcium carbonate) powder

[0059]

[0060] 1. Heating of pretreated phosphoric acid and neutralization of calcium powder to make pulp

[0061] ① Pretreatment wet process phosphoric acid comes from phosphoric acid storage tank, P 2 o 5 The concentration is 30.5%, the specific gravity is 1.33g / ml, the temperature is 40°C; at 33.305m 3 The flow rate per hour ...

Embodiment 3

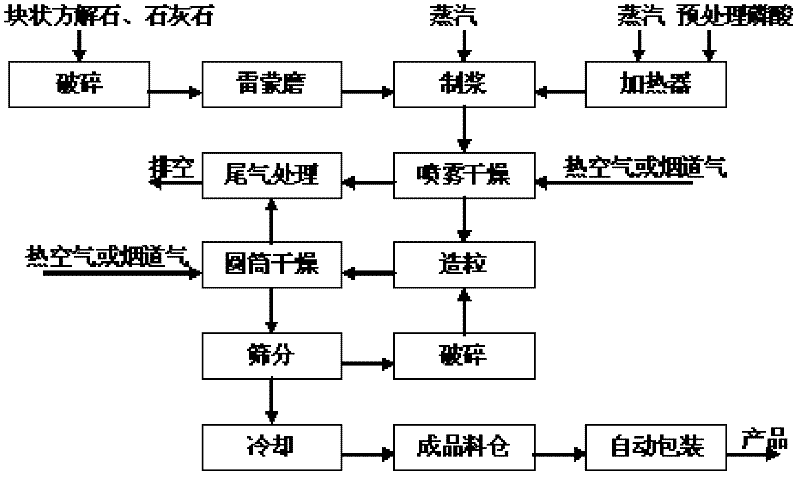

[0071] Embodiment 3 adopts the inventive method to produce granular feed grade calcium hydrogen phosphate III type

[0072] Follow these steps:

[0073] 1. Heating of pretreated phosphoric acid and neutralization of calcium powder to make pulp;

[0074] 2. Spraying, granulation and secondary drying of slurry;

[0075] 3. Screening and crushing of granular materials, cooling and packaging of finished products.

[0076] The quality index of pretreatment phosphoric acid and heavy calcium (calcium carbonate) powder is as shown in table 5.

[0077] The quality index of table 5 pretreatment phosphoric acid and heavy calcium (calcium carbonate) powder

[0078]

[0079] 1. Heating of pretreated phosphoric acid and neutralization of calcium powder to make pulp

[0080] ① Pretreatment wet process phosphoric acid comes from phosphoric acid storage tank, P 2 o 5 The concentration is 33.0%, the specific gravity is 1.36g / ml, the temperature is 40°C; at 30.10m 3 The flow rate per h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com