Chromium salt production method with recyclable auxiliary materials

A production method and technology for chromium salts are applied in the field of chromium salt production with recyclable auxiliary materials, which can solve the problems affecting product quality and performance, difficult to guarantee product quality, difficult alkali circulation and regeneration, etc., so as to reduce material consumption and shorten time. , the effect of reducing production costs and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

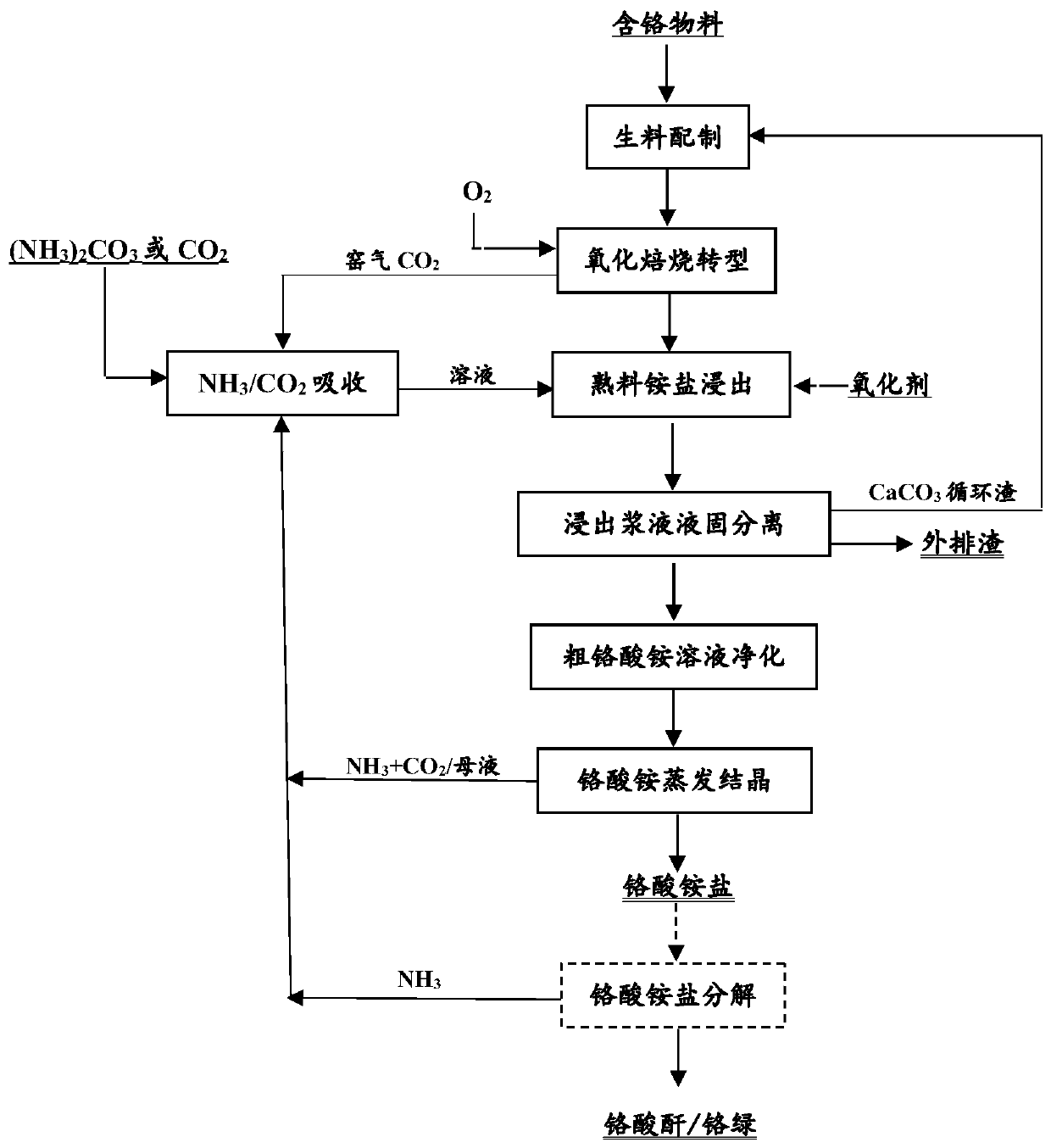

[0037] A kind of auxiliary material recyclable chromium salt production method of the present invention, as figure 1 shown, including the following steps:

[0038] (1) A certain chromite (Cr 2 o 3 The mass percent content is 50.46%) and calcium carbonate according to CaCO 3 / Cr 2 o 3 The molar ratio is 3.3, and the raw meal is obtained by grinding and mixing, and the particle size of the raw meal is less than 90 μm;

[0039] (2) Under an air atmosphere, the raw meal is oxidized and roasted in a roaster at 850°C for 2 hours to obtain clinker and produce carbon dioxide at the same time;

[0040] (3) After the clinker is cooled to room temperature, grind it finely with a vibrating mill, and the clinker particle size is <70 μm. Take 5.0 g of clinker and put it into 50 ml of ammonium carbonate concentration in the leaching solution of 200 g / L, and add 5 ml of mass concentration to the solution. Use 30% hydrogen peroxide as an oxidant, stir and leaching for 2 hours under airti...

Embodiment 2

[0045] A kind of auxiliary material recyclable chromium salt production method of the present invention, as figure 1 shown, including the following steps:

[0046] (1) A certain chromite (Cr 2 o 3 The mass percent content is 50.46%) and calcium carbonate according to CaCO 3 / Cr 2 o 3 The molar ratio is 3.6, and the raw meal is obtained by grinding and mixing, and the particle size of the raw meal is less than 45 μm;

[0047] (2) Under the air atmosphere, the raw material is oxidized and roasted in a roaster at 850°C for 3 hours to obtain clinker, and carbon dioxide is produced at the same time. It is tested that the main chromium-calcium compound in the clinker is Ca 5 (CrO 4 ) 3 o 0.5 ;

[0048] (3) Add clinker, leaching agent and oxidant to the ball mill leaching device for leaching, the leaching agent is saturated ammonium carbonate solution, the oxidizing agent is hydrogen peroxide, and the amount of leaching agent is the theoretical amount needed to convert chrom...

Embodiment 3

[0053] A kind of auxiliary material recyclable chromium salt production method of the present invention, as figure 1 shown, including the following steps:

[0054] (1) A certain chromite (Cr 2 o 3 The mass percentage composition is 50.46%) and the obtained filter cake in embodiment 2 presses CaCO 3 / Cr 2 o 3 The molar ratio is 3.0, and the raw meal is obtained by grinding and mixing, and the particle size of the raw meal is less than 45 μm;

[0055] (2) Under the air atmosphere, the raw material is oxidized and roasted in a roaster at 850°C for 3 hours to obtain clinker, and carbon dioxide is produced at the same time. It is tested that the main chromium-calcium compound in the clinker is Ca 5 (CrO 4 ) 3 o 0.5 ;

[0056](3) Add clinker, leaching agent and oxidant to the ball mill leaching device for leaching, the leaching agent is saturated ammonium carbonate solution, the oxidizing agent is hydrogen peroxide, and the amount of leaching agent is the theoretical amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com