Hot-melt pressure-sensitive adhesive for cotton packaging film and preparation method of hot-melt pressure-sensitive adhesive

A technology for hot-melt pressure-sensitive adhesives and films, applied in the direction of pressure-sensitive films/sheets, adhesives, heat-activated films/sheets, etc., can solve the problem of large temperature difference between day and night, weather resistance performance needs to be improved, and easy occurrence of bonding at the packaging film Displacement and warping and other problems, to achieve the effect of not easy displacement and warping, strong peeling performance, and excellent application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A hot-melt pressure-sensitive adhesive for cotton packaging film, each component and its corresponding weight are shown in Table 1, and prepared by the following steps:

[0042] (1) Prepare raw materials comprising thermoplastic elastomer, tackifying resin, plasticizer, antioxidant and stabilizer by proportioning;

[0043] (2) Set the temperature in the vacuum stirred tank to 180°C, add plasticizer, stabilizer and antioxidant to the reactor in sequence and put thermoplastic elastomer into it to stir for 90 minutes;

[0044] (3) Add tackifying resin, pass into nitrogen protection and continue to stir for 30min;

[0045] (4) Vacuumize the hydraulic pressure to discharge the material, and cool down to obtain the finished product;

[0046] In the above steps: the thermoplastic elastomer is composed of styrene-isoprene-styrene block copolymer and styrene-butadiene-styrene block copolymer, and styrene-isoprene-styrene block copolymer The mass mixing ratio of segment copolym...

Embodiment 2-6

[0051] A hot-melt pressure-sensitive adhesive for cotton packaging film, the difference from Example 1 is that each component and its corresponding weight are shown in Table 1.

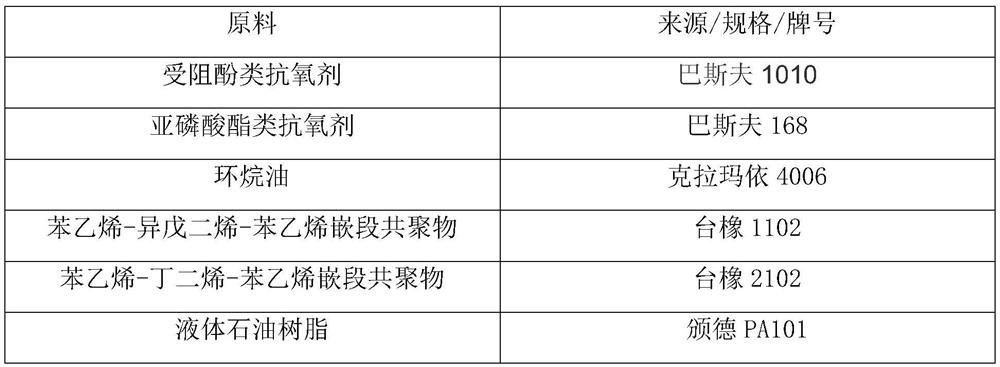

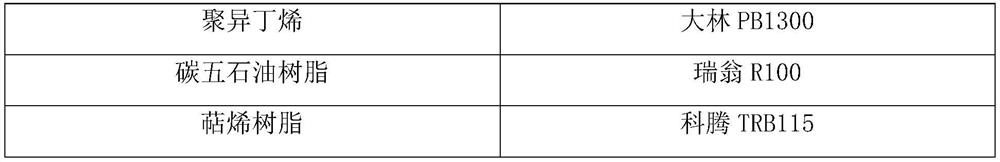

[0052] Each component and its weight (kg) in table 1 embodiment 1-6

[0053]

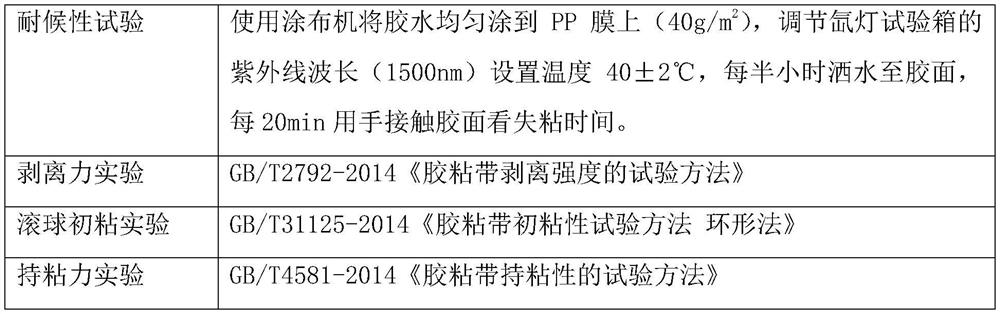

[0054] The performance detection result of table 2 embodiment 1-3

[0055]

[0056]

[0057] From the data in Table 2, it can be seen that the raw materials of each component of the hot-melt pressure-sensitive adhesive for cotton packaging film are taken within the range of proportioning, which can make the obtained product maintain excellent and stable application performance, and among them the The performance of the product obtained by the ratio of each raw material is optimal.

Embodiment 7

[0059] A hot-melt pressure-sensitive adhesive for cotton packaging film, the difference from Example 1 is that styrene-isoprene-styrene block copolymer and styrene-butadiene-styrene block copolymer The mass mixing ratio of the substance is 1:0.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com