Saccharomyces cerevisiae for improving flavor of noodles, leavening agent, application of leavening agent and method for preparing flour products through fermentation

A technology of Saccharomyces cerevisiae and starter, applied in the field of food processing, which can solve the problems of low fermentation efficiency, long cooking time, and poor product flavor, and achieve the effects of high fermentation efficiency, short cooking time, and unique flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

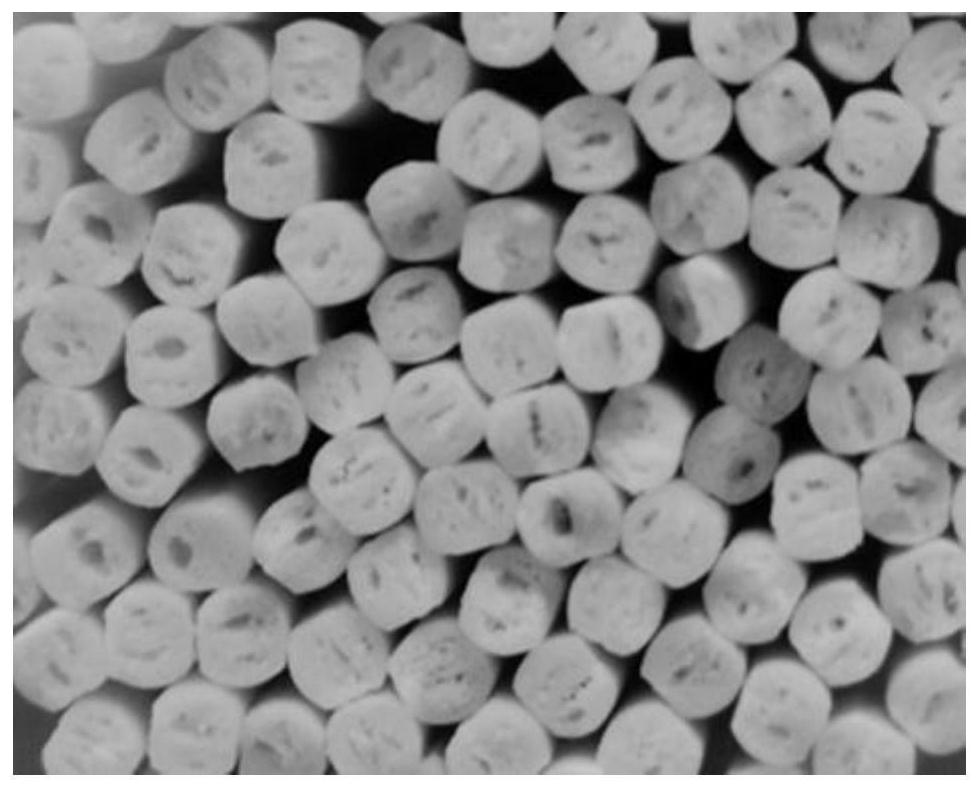

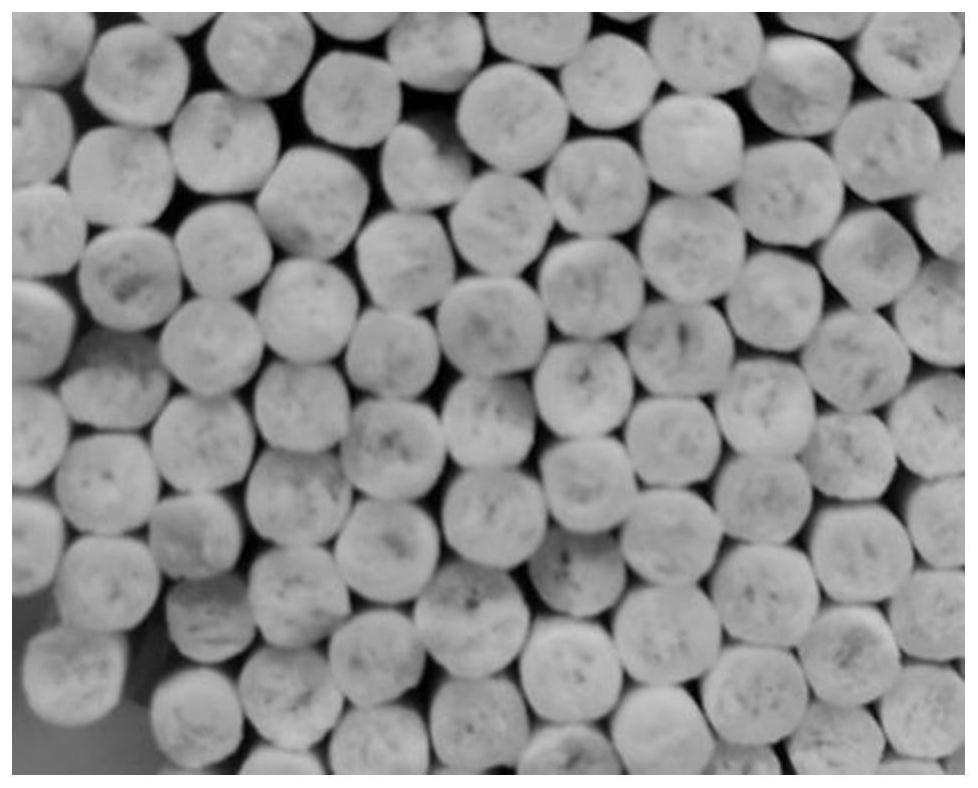

Image

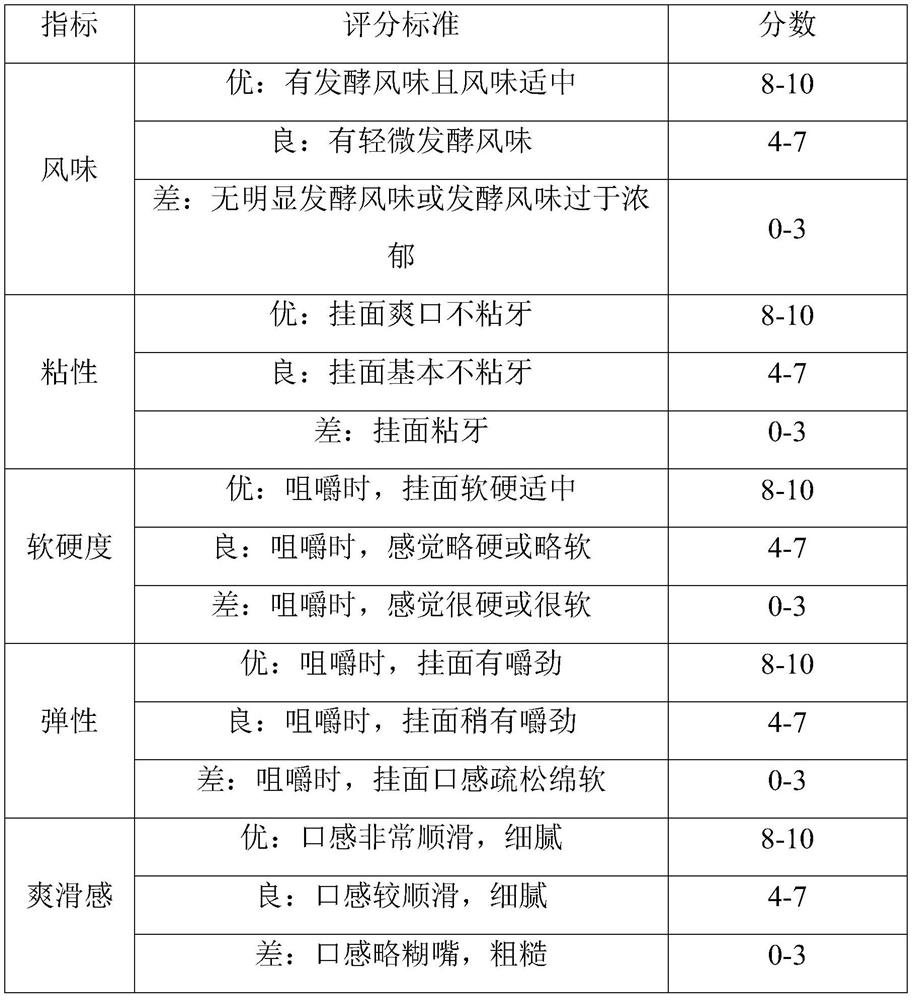

Examples

preparation example 1

[0080] Method 1: Saccharomyces cerevisiae CGMCC NO.21161 is fermented in the fermentation medium (28±1°C, 8-15h), so that the number of viable bacteria reaches 1×10 8 CFU / mL to obtain liquid starter A.

[0081] Saccharomyces cerevisiae CGMCC NO.21161 and Lactobacillus plantarum CGMCC NO.21158 were respectively fermented and cultured in the fermentation medium, and then the cultivated Saccharomyces cerevisiae and Lactobacillus plantarum were mixed until the total number of live bacteria reached 1×10 8 CFU / mL (Saccharomyces cerevisiae:Lactobacillus plantarum=1:0.06), to obtain liquid starter B.

[0082] Method 2: Mix the liquid starter A (or B) with the fermentation substrate (ie flour) according to the weight ratio of 1:200, so that the liquid starter can be converted into a semi-liquid starter, and the semi-liquid starter A (or B).

[0083] Method 3: The semi-liquid starter A (or B) is subjected to solid-liquid separation (centrifugation at 8000 rpm for 10 min at 4°C in a re...

Embodiment 1

[0086] Adopt the following method to carry out the making of fermented vermicelli A-1:

[0087] (1) Activation of fermentation agent: Weigh 0.5 parts of liquid starter A obtained in Preparation Example 1 and 1 part of white sugar, add 35 parts of water and mix evenly (specific conditions: 30 rpm stirring for 2 min), and then carry out at 42 ° C. Activate for 5 minutes. In the activated fermentation agent, the content of Saccharomyces cerevisiae is 1×10 8 CFU / mL.

[0088] (2) Kneading dough: according to the ratio of 100g flour corresponding to 35mL of the activated fermentation agent, the flour and the activated fermentation agent are poured into a chef's machine (KVC3100 type) purchased from Kenwood (KENWOOD) company and stirred. After stirring slowly at 30rpm for 5 minutes, stir rapidly at 80rpm for 10 minutes to form a uniform flour floc. Then, the obtained flour wadding is fermented, and the specific fermenting condition is 30° C. and left standing for 20 minutes. Obta...

Embodiment 2

[0097] Adopt the following method to carry out the making of fermented vermicelli A-2:

[0098] (1) Activation of fermentation agent: Weigh 1 part of dry starter A obtained in Preparation Example 1 and 1 part of white granulated sugar, add 38 parts of water and mix evenly (specific conditions: 30rpm stirring for 2min), and then carry out at 35°C Activate for 10 minutes. In the activated fermentation agent, the content of Saccharomyces cerevisiae is 1×10 9 CFU / mL.

[0099] (2) Kneading the dough: according to the ratio of 100g flour corresponding to 30mL of the activated fermentation agent, the flour and the activated fermentation agent are poured into a chef's machine (KVC3100 type) purchased from Kenwood (KENWOOD) company and stirred. After stirring slowly at 40rpm for 3 minutes, stir rapidly at 90rpm for 5 minutes to form a uniform flour floc. Then, the obtained flour wadding is fermented, and the specific fermenting condition is 28° C. and left to stand for 40 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com