Combustion stove for granular fuel

A technology for pellet fuel and stove, which is applied in the field of pellet fuel combustion stove, can solve the problems of not being able to achieve efficient and stable combustion at the same time, inconvenient to adjust the fuel height, unable to adapt the flame height, etc., and achieves convenient and unified processing and novel structure , reduce the effect of normal combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

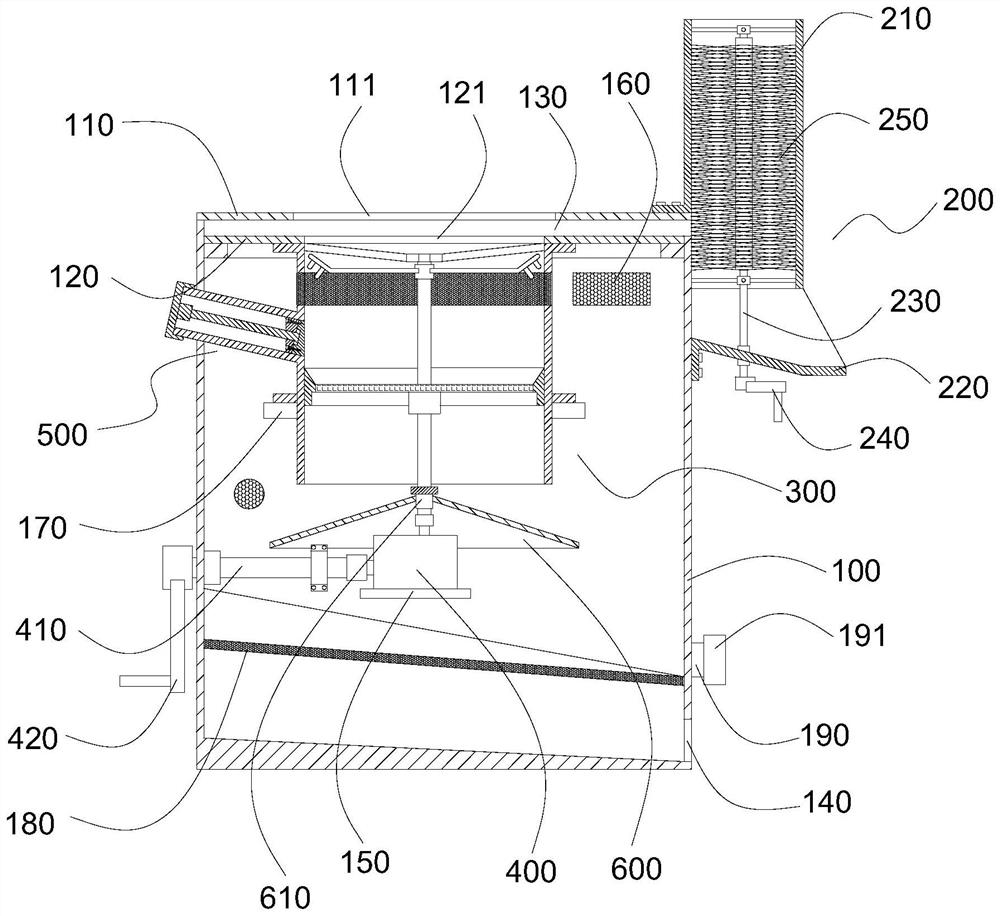

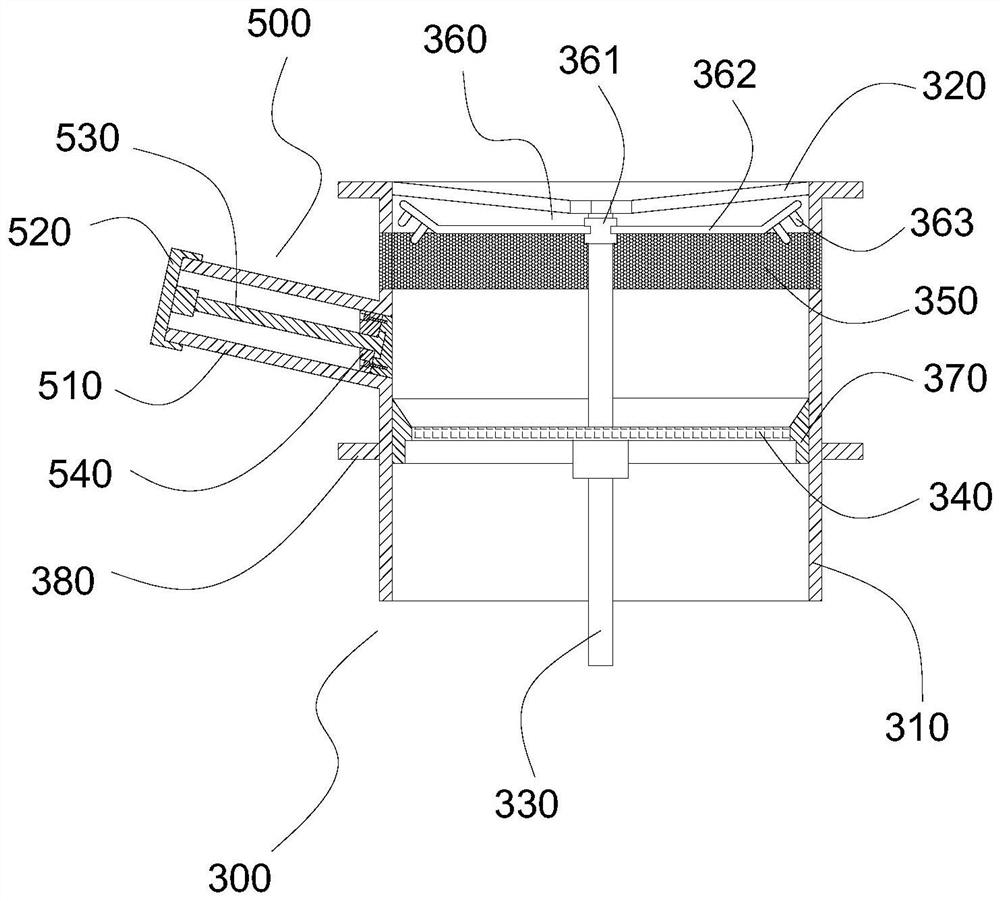

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] Such as figure 1 , figure 2 As shown, a specific embodiment of the present invention discloses a combustion stove for particulate fuel, including a box body 100, a box cover 110 fixed on the top of the box body 100, and a first through hole 111 is opened in the middle of the box cover 110, The top of the inner wall of the box body 100 is fixed with a supporting plate 120, and the supporting plate 120 is correspondingly opened with a second through hole 121. A sandwich chamber 130 for moving smoke is formed between the supporting plate 120 and the box cover 110. One of the sandwich chambers 130 The side extends to the outer wall of the box body 100, and the flue gas treatment device 200 is installed in the opening of the outer wall of the box body 100 corresponding to the clamp cavity 130, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com