Control method of wind powder multi-parameter online detection device

A control method and detection device technology, which are applied in measurement devices, fluid velocity measurement, suspension and porous material analysis, etc., can solve problems such as clogging of the backrest tube for measuring flow velocity, inability to use real-time feedback control, and insufficient measurement accuracy, etc. Stable combustion, solving the inability to achieve online detection and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

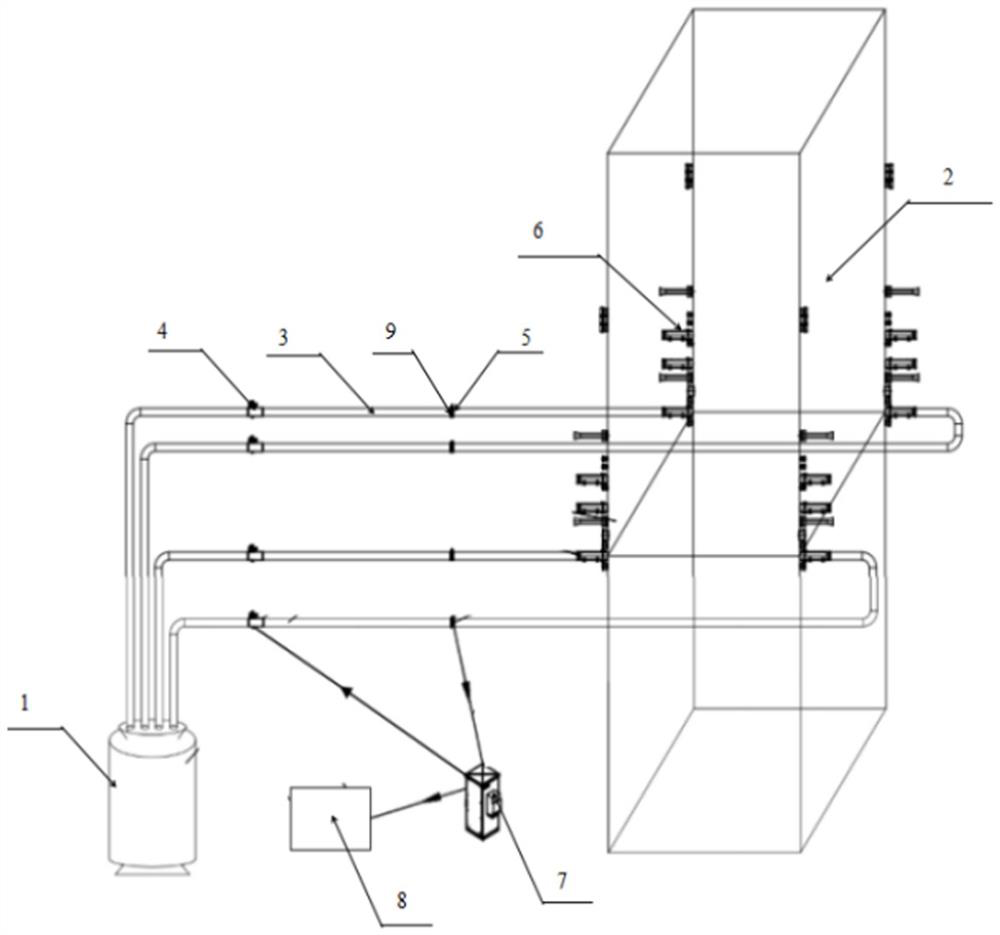

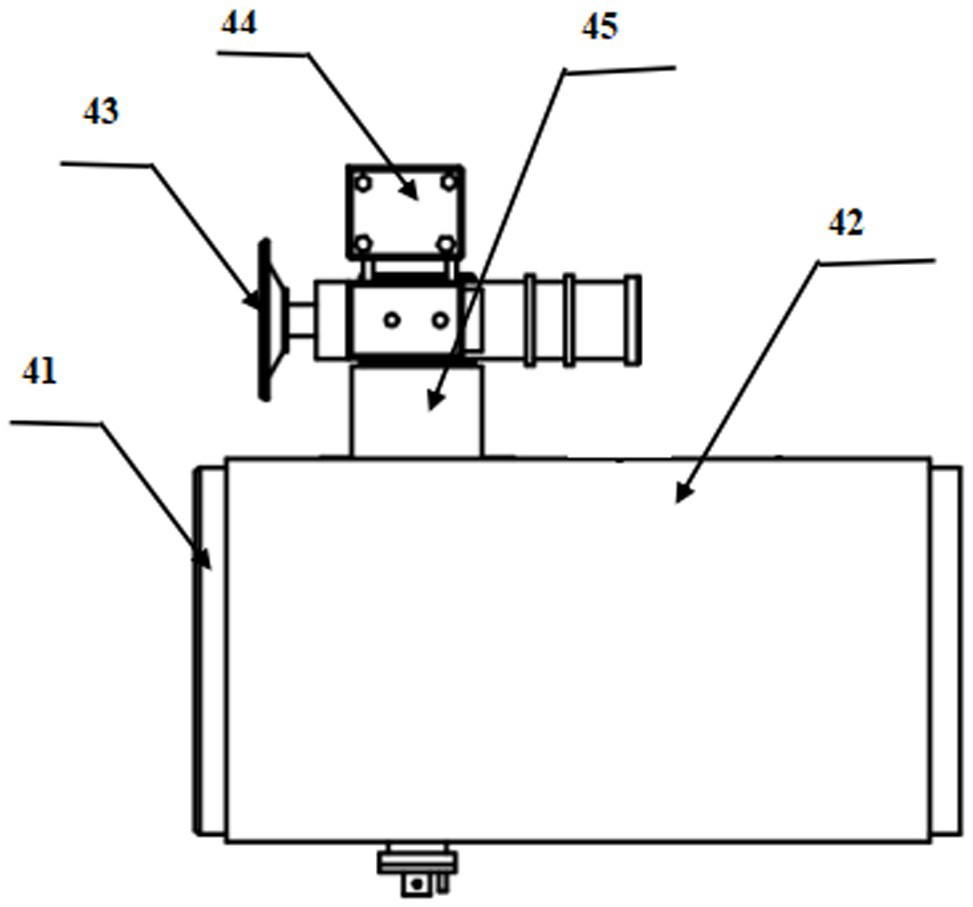

[0042] As mentioned in the background technology, in view of the problems in the prior art, this application proposes a wind powder multi-parameter online detection device, which is installed in the wind powder mixing pipeline 3, and one end of the wind powder mixing pipeline 3 is connected to the burner 9, and the other end is connected with the coal mill 1; the boiler 2 is provided with a plurality of said burners 9, and each said burner 9 is connected with said air-powder mixing pipeline 3, as figure 1 As shown, the online detection device includes:

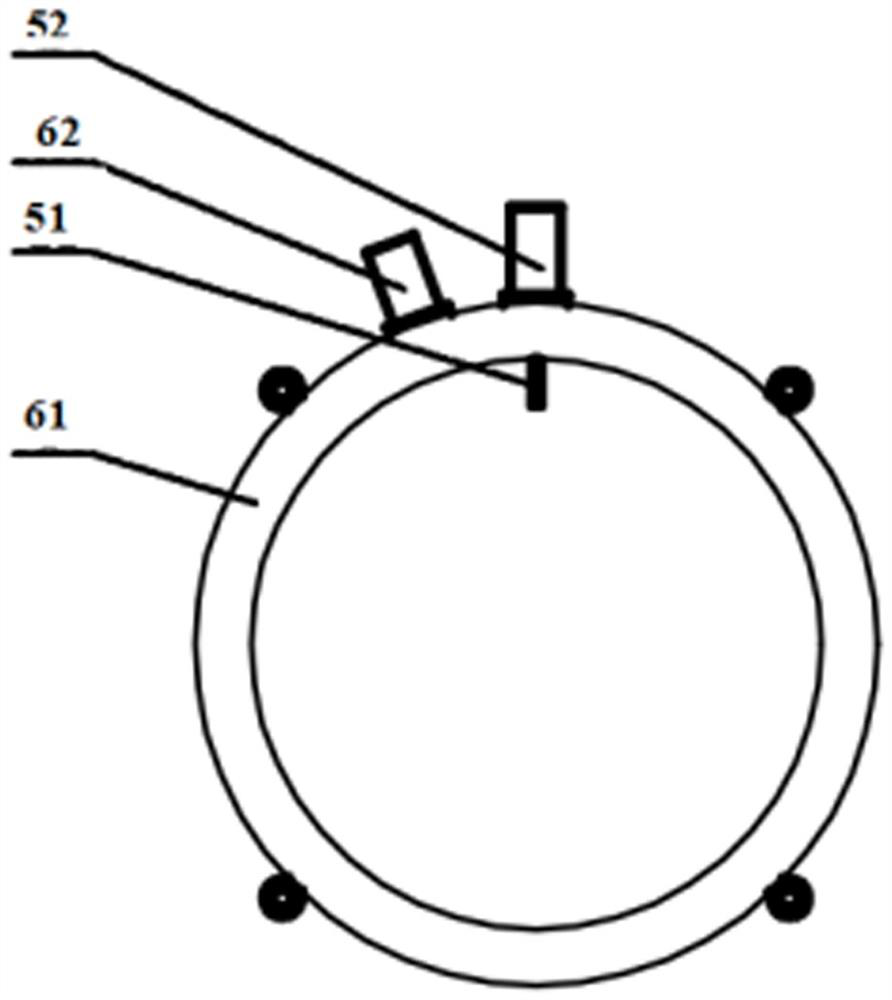

[0043] The first detection component 6, each of the wind powder mixing pipeline 3 is provided with the first detection component 6, which is used to obtain the flow velocity of the powder particles in the wind powder mixing pipeline 3; specifically, as figure 2 The first detection component 6 is a gas-solid two-phase detection component, including a base 61, an electrode, and a signal processing unit 62. Preferably, the base ...

Embodiment 2

[0063] On the basis of Embodiment 1, the application proposes a control method for an air powder multi-parameter online detection device. A plurality of burners 9 are arranged on the boiler 2 along its height direction, each of which is connected to a wind turbine. Powder mixing pipeline 3, each wind powder mixing pipeline 3 is provided with wind powder control and equalization assembly 4, and the control method includes the following steps:

[0064] S10. Obtain the flow velocity of the powder particles in at least two of the air-powder mixing pipelines 3, which is called the first flow velocity; this embodiment uses the first detection component 6 described in Embodiment 1 to detect the air-powder mixing pipeline The flow rate of the powder particles in 3;

[0065] S20. Select the first flow rate with the smallest value as the second flow rate; each of the first detection components 6 transmits the obtained first flow rate of the powder particles to the control processing cen...

Embodiment 3

[0069] The same as Embodiment 2 will not be repeated, the difference is: the boiler 2 is provided with a plurality of burner groups along its height direction, and each group of the burner groups includes a plurality of the burner 9, so Described control method comprises the following steps:

[0070] S50. Obtain the flow velocity of the powder particles passing into each of the burners 9, and set it as the third flow velocity; the difference between this embodiment and the embodiment 2 is that there are multiple Burners 9, the burners 9 of the same height form a burner group;

[0071] S60. Select the minimum flow velocity among the third flow velocities in each group and set it as the fourth flow velocity to obtain a fourth flow velocity set, the fourth flow velocity set includes the minimum flow velocity of each set of the burner groups; in this embodiment The concept of the control method is: first compare the flow rate of the powder particles passing into the burner groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com