Fuel cell membrane electrode ionomer pretreatment method

A fuel cell membrane, ionomer technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problem of unfavorable catalytic layer high-activity reaction interface construction and strength, affecting the two-phase distribution of ionomer and catalyst, and inability to ionomerize Dispersion and shape regulation, etc., to prevent air mixing, short dispersion time, and avoid air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

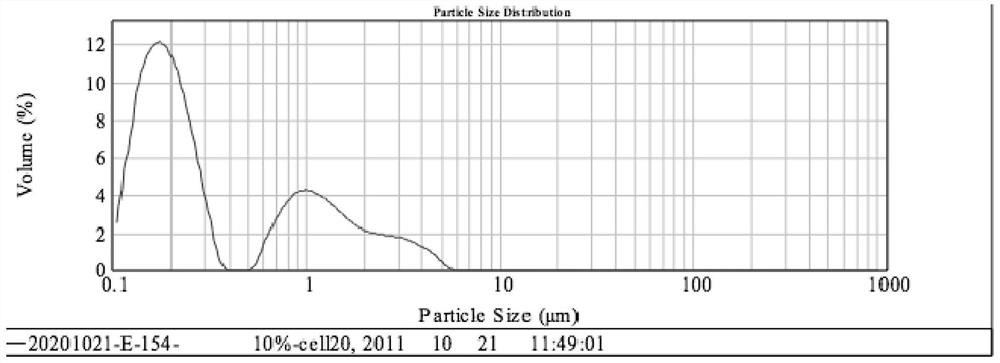

[0042] A fuel cell membrane electrode ionomer pretreatment method, comprising the following steps:

[0043] (1) Weigh 1 part of the ionomer dispersion and place it in a beaker, weigh 10 parts of pure water and 3 parts of ethanol, add the ionomer dispersion and stir to mix evenly;

[0044] (2) Put the premixed ionomer dispersion in a closed high-speed shearing machine, turn on the cooling system, maintain the slurry temperature at 25°C, shear the line speed at 20m / s, and shear for 5 minutes, and the process is complete Pretreatment of ionomers.

[0045] (3) then the pretreated ionomer is mixed with catalyst, water, and ethanol, and the mass ratio of each component is: 1 part of catalyst, 10 parts of water, 10 parts of ethanol, 4 parts of ionomer; The material was dispersed by ultrasonic wave for 20 minutes, the ultrasonic power was 500W, and the temperature of the slurry was controlled at 25°C. That is, the desired catalyst slurry is prepared.

Embodiment 2

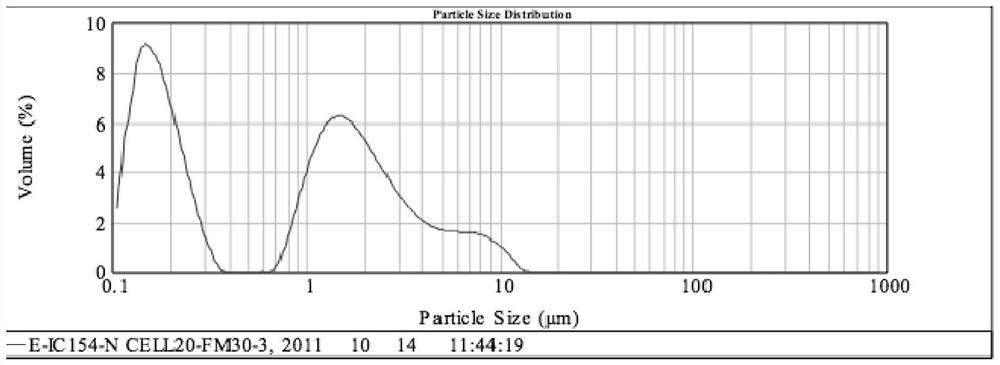

[0047] A fuel cell membrane electrode ionomer pretreatment method, comprising the following steps:

[0048] (1) Weigh 1 part of the ionomer dispersion and place it in a beaker, weigh 10 parts of pure water and 3 parts of n-propanol, add the ionomer dispersion and stir to mix evenly;

[0049] (2) Put the premixed ionomer dispersion in a closed high-speed shearing machine, turn on the cooling system, maintain the slurry temperature at 25°C, the shearing line speed at 20m / s, and the shearing time for 2 minutes, and the process is completed Pretreatment of ionomers.

[0050] (3) Then the pretreated ionomer is mixed with catalyst, water, and n-propanol, and the mass ratio of each component and the slurry dispersion process are consistent with Example 1. That is, the desired catalyst slurry is prepared.

Embodiment 3

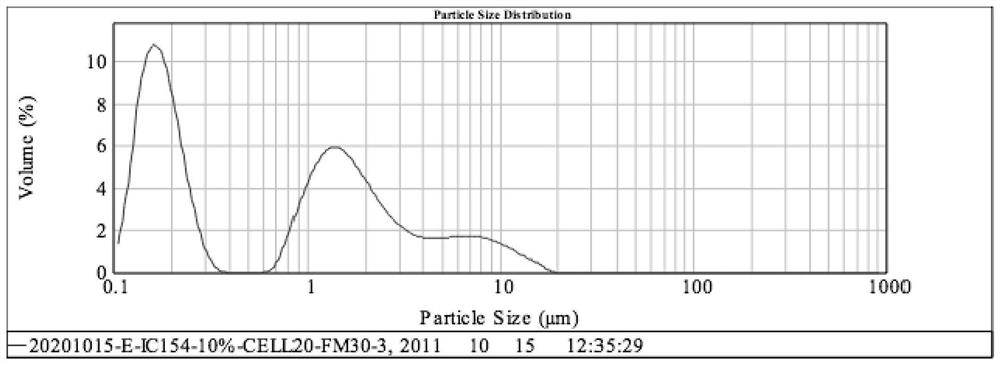

[0052] A fuel cell membrane electrode ionomer pretreatment method, comprising the following steps:

[0053] (1) Weigh 1 part of the ionomer dispersion and place it in a beaker, weigh 10 parts of pure water and 2 parts of ethanol, add the ionomer dispersion and stir to mix evenly;

[0054] (2) Put the premixed ionomer dispersion in a closed high-speed shearing machine, turn on the cooling system, maintain the slurry temperature at 25°C, the shearing line speed at 30m / s, and the shearing time for 5 minutes, and the process is complete Pretreatment of ionomers.

[0055] (3) Then the pretreated ionomer is mixed with catalyst, water, and ethanol, and the mass ratio of each component and the slurry dispersion process are consistent with Example 1. That is, the desired catalyst slurry is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com