Production equipment, mixed precipitate prepared by using equipment, and method and application of mixed precipitate

A production equipment and equipment technology, applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems of slow mixing and precipitation reaction, impure products, large particles, etc., to improve the purity of sediments, reduce The effect of coating and improving the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

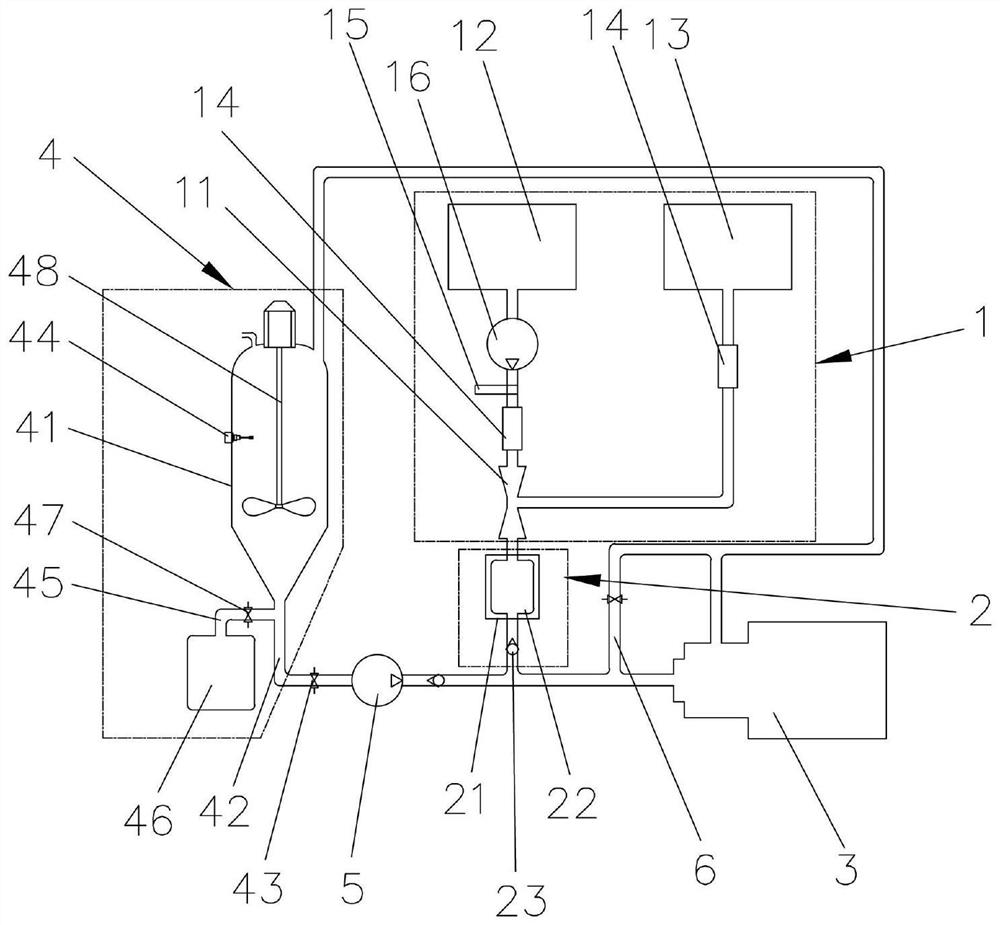

[0079] like figure 1 As shown, a production equipment, including

[0080] Liquid mixing equipment 1, used to mix the raw material components to obtain a mixed liquid;

[0081] Ultrasonic dispersing device 2, communicated with liquid mixing device 1, for ultrasonically dispersing the mixed liquid to obtain the first treatment liquid;

[0082] Homogenizing device 3, communicated with ultrasonic dispersing device 2, for homogenizing the first treatment liquid to obtain the second treatment liquid;

[0083] The storage device 4 is in communication with the homogenization device 3, and is used to statically treat the second treatment liquid to obtain a generated liquid;

[0084] Wherein, the liquid mixing device 1 includes a Venturi tube 11, a first liquid storage tank 12 communicated with the inlet end of the Venturi tube 11, and a second liquid storage tank 13 communicated with the throat of the Venturi tube 11, the Venturi tube The outlet end of the inner tube 11 communicates...

Embodiment 2

[0092] like figure 1 As shown, a production equipment, including

[0093] Liquid mixing equipment 1, used to mix the raw material components to obtain a mixed liquid;

[0094] Ultrasonic dispersing device 2, communicated with liquid mixing device 1, for ultrasonically dispersing the mixed liquid to obtain the first treatment liquid;

[0095] Homogenizing device 3, communicated with ultrasonic dispersing device 2, for homogenizing the first treatment liquid to obtain the second treatment liquid;

[0096] The storage device 4 is in communication with the homogenization device 3, and is used to statically treat the second treatment liquid to obtain a generated liquid;

[0097] And a circulation device 5, the circulation device 5 is used to sequentially transport the generated liquid to the homogenization device 3 and the storage device 4;

[0098] Wherein, the liquid mixing device 1 includes a Venturi tube 11, a first liquid storage tank 12 communicated with the inlet end of t...

Embodiment 3

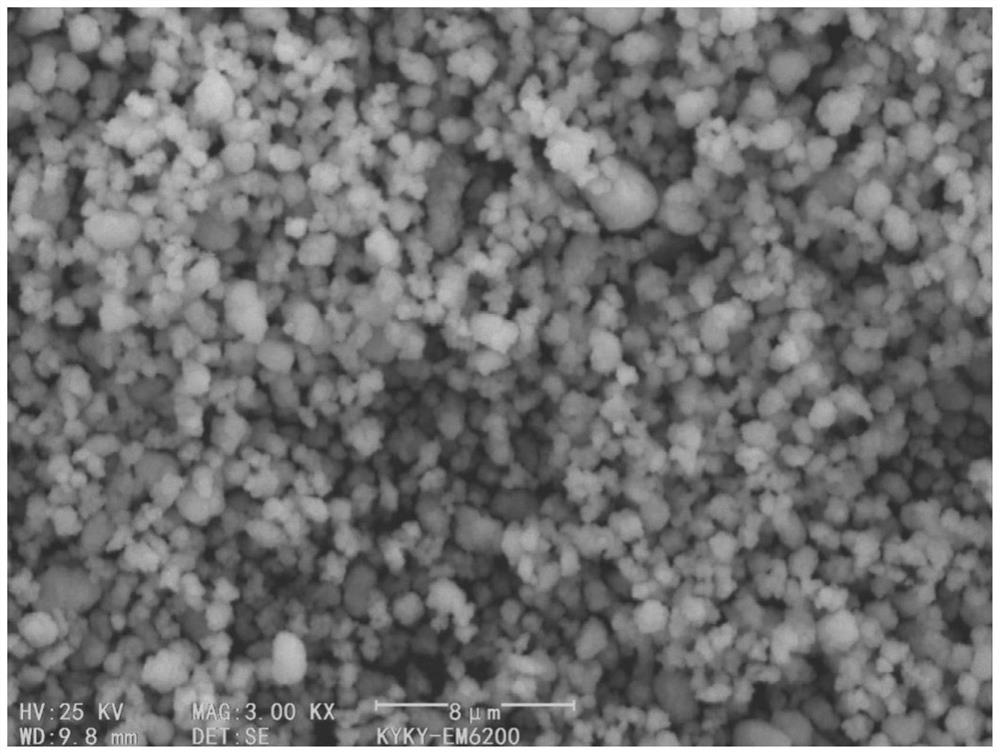

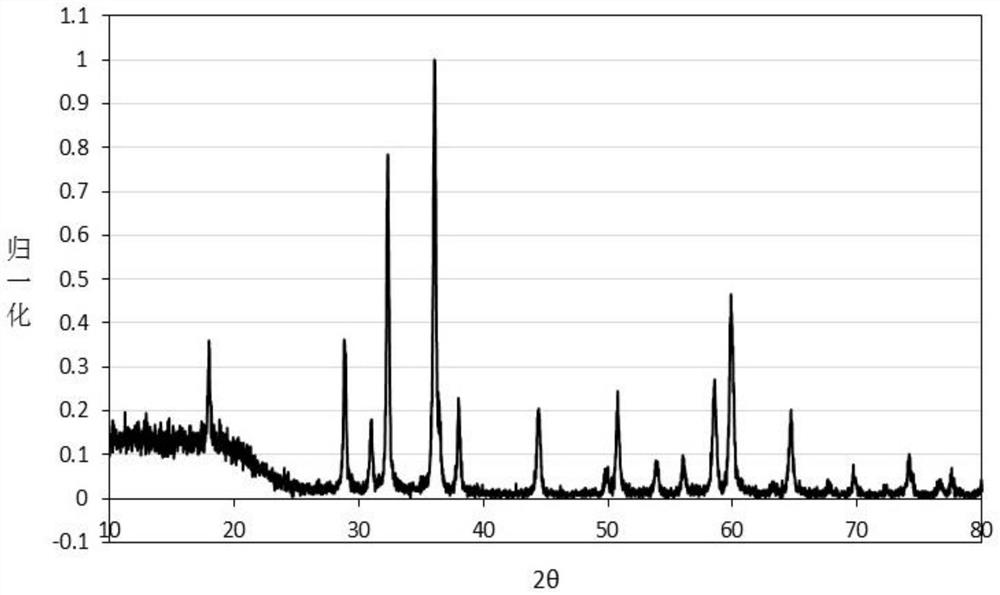

[0104] Preparation of soluble salt mixed precipitate: preparation of 5mol / L nickel sulfate (NiSO 4 ), 2mol / L cobalt sulfate (CoSO 4 ), 3mol / L manganese sulfate (MnSO 4 ) mixed aqueous solution 5L, that is, weigh 1320.1g of NiSO 4 ·6H 2 O, 566.1g of CoSO 4 ·7H 2 O and 508.7g of MnSO 4 ·H 2 O, after dissolving with 3000g of deionized water at about 50°C, set the volume to 5L and store it in the first liquid storage tank 41; prepare 5L of 10mol / L sodium carbonate solution by weighing 1060g of Na 2 CO 3 After dissolving with 4000g of deionized water at about 50°C, set the volume to 5L and store in the second liquid storage tank 41; adjust the volume ratio of soluble salt to precipitant to 1:1 and perform dynamic mixing and feeding in liquid mixing equipment 1, The first raw material solution enters through the inlet end of the Venturi tube 11, and the second raw material solution enters through the throat of the Venturi tube 11, so that the first raw material solution and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com