Dental implant with local functionalization of biomimetic gradient modulus and its preparation method

A dental implant and functionalized technology, applied in dentistry, dental implants, manufacturing tools, etc., can solve problems such as the mismatch between the elastic modulus of the dental implant and the alveolar bone, and the implant is easy to loosen, so as to improve the osteogenic potential. , low cost of raw materials, easy to loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a dental implant with bionic gradient modulus local functionalization, comprising the following steps:

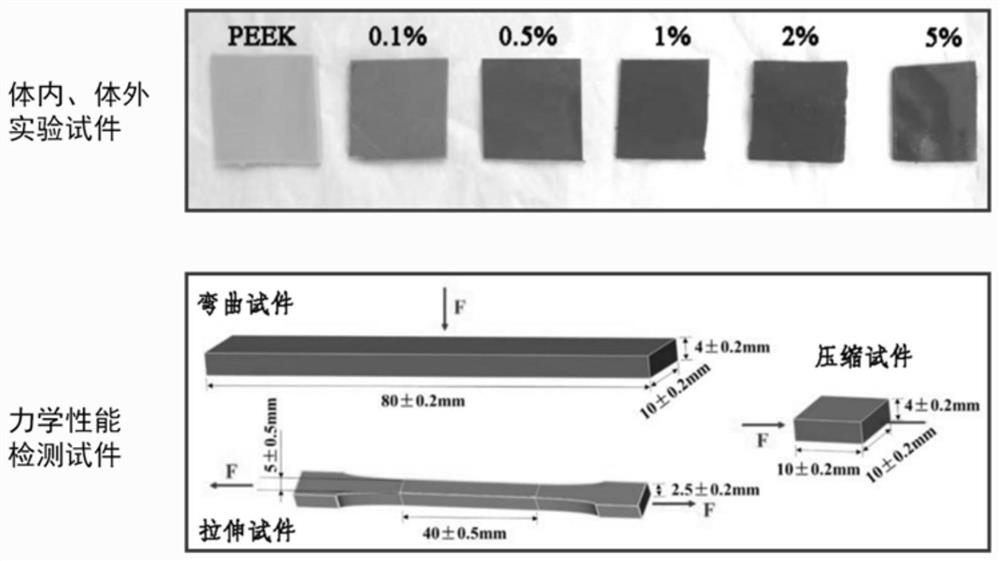

[0035] (1) Mix 1wt% nano-graphene and polyetheretherketone to obtain a mixture, then add 8ml of absolute ethanol to each gram of the mixture, stir magnetically at room temperature for 20min, vacuum filter and dry at 55°C in turn , to obtain 1wt% nano-graphene / polyetheretherketone mixed powder; adopt the same method to obtain 5wt% nano-graphene / polyetheretherketone mixed powder;

[0036] (2) Design the digital model of the dental implant, and then follow the plan of the dental implant from bottom to top and gradually transition from 5wt% nanographene / polyetheretherketone mixed powder to 1wt% nanographene / polyetheretherketone mixed powder Gradient material function modeling, and set the printing path to select each layer printing deflection 90 °, and then the 1wt% nano-graphene / polyetheretherketone mixed powder and 5wt% nano-graphene / polyether e...

Embodiment 2

[0038] A preparation method of a dental implant with bionic gradient modulus local functionalization, comprising the following steps:

[0039] (1) Mix 1wt% nano-graphene and polyetheretherketone to obtain a mixture, then add 10ml of absolute ethanol to each gram of the mixture, stir magnetically at room temperature for 30min, vacuum filter and dry at 60°C in turn , to obtain 1wt% nano-graphene / polyetheretherketone mixed powder; adopt the same method to obtain 5wt% nano-graphene / polyetheretherketone mixed powder;

[0040] (2) Design the digital model of the dental implant, and then follow the plan of the dental implant from bottom to top and gradually transition from 5wt% nano-graphene / polyetheretherketone mixed powder to 1wt% nano-graphene / polyether ether ketone mixed powder Gradient material function modeling, and set the printing path to select each layer printing deflection 90 °, and then the 1wt% nano-graphene / polyetheretherketone mixed powder and 5wt% nano-graphene / polyet...

Embodiment 3

[0042]A preparation method of a dental implant with bionic gradient modulus local functionalization, comprising the following steps:

[0043] (1) Mix 1wt% nano-graphene and polyetheretherketone to obtain a mixture, then add 12ml of absolute ethanol to each gram of the mixture, stir magnetically at room temperature for 40min, vacuum filter and dry at 65°C in turn , to obtain 1wt% nano-graphene / polyetheretherketone mixed powder; adopt the same method to obtain 5wt% nano-graphene / polyetheretherketone mixed powder;

[0044] (2) Design the digital model of the dental implant, and then follow the plan of the dental implant from bottom to top and gradually transition from 5wt% nanographene / polyetheretherketone mixed powder to 1wt% nanographene / polyetheretherketone mixed powder Gradient material function modeling, and set the printing path to select each layer printing deflection 90 °, and then the 1wt% nano-graphene / polyetheretherketone mixed powder and 5wt% nano-graphene / polyether e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com