Manipulator full-automatic tooth table grinding machine

A fully automatic, grinding machine technology, applied in the field of grinding machines, can solve the problems of gear grinding accuracy, unfavorable collection and handling, hidden dangers of hand safety, etc., to achieve convenient cleaning and collection, avoid waste debris splashing, and improve protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

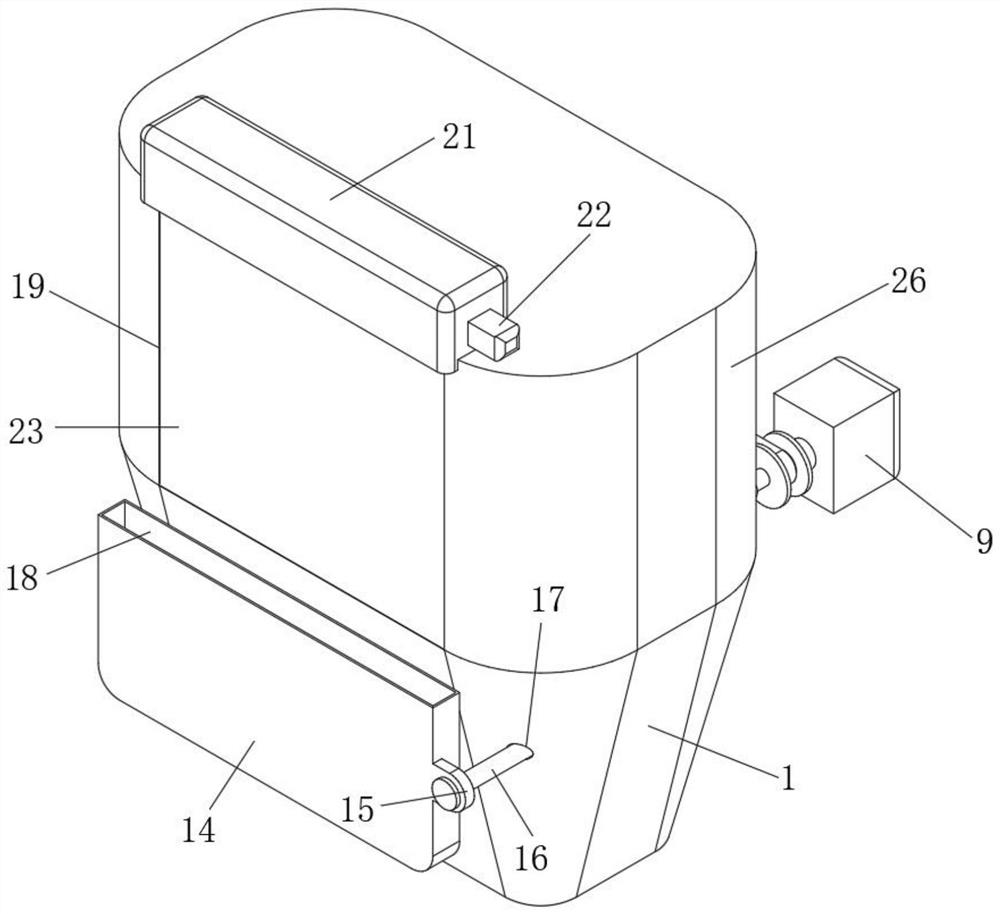

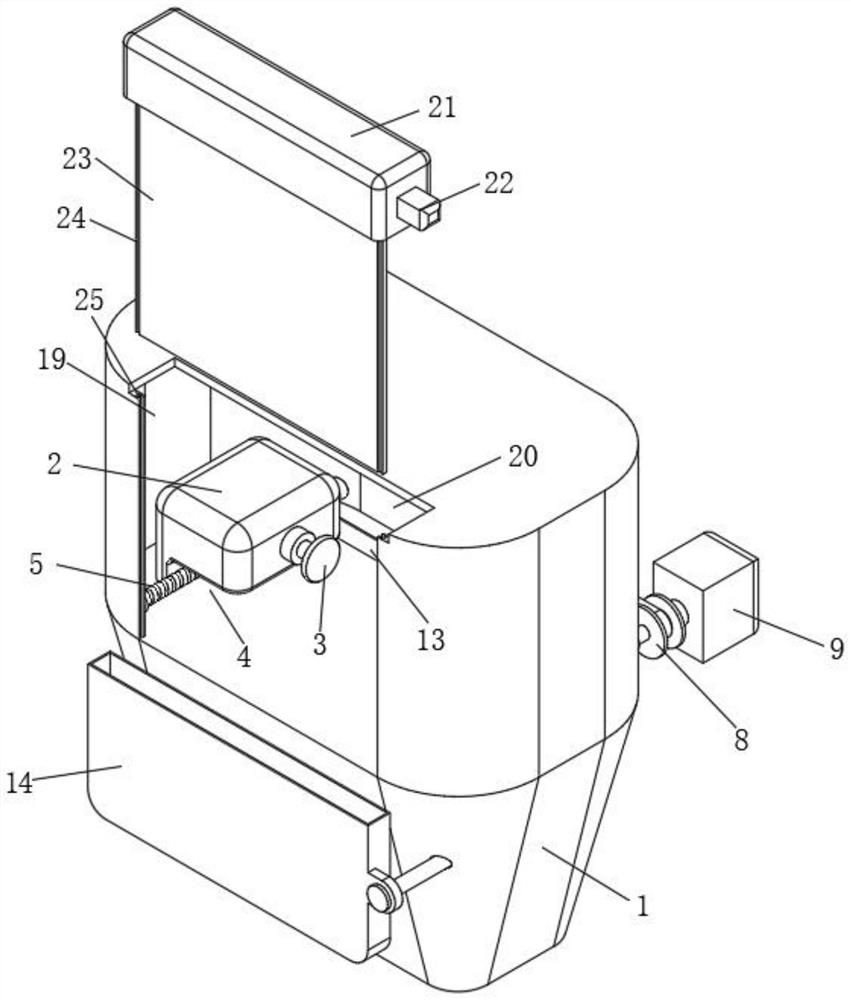

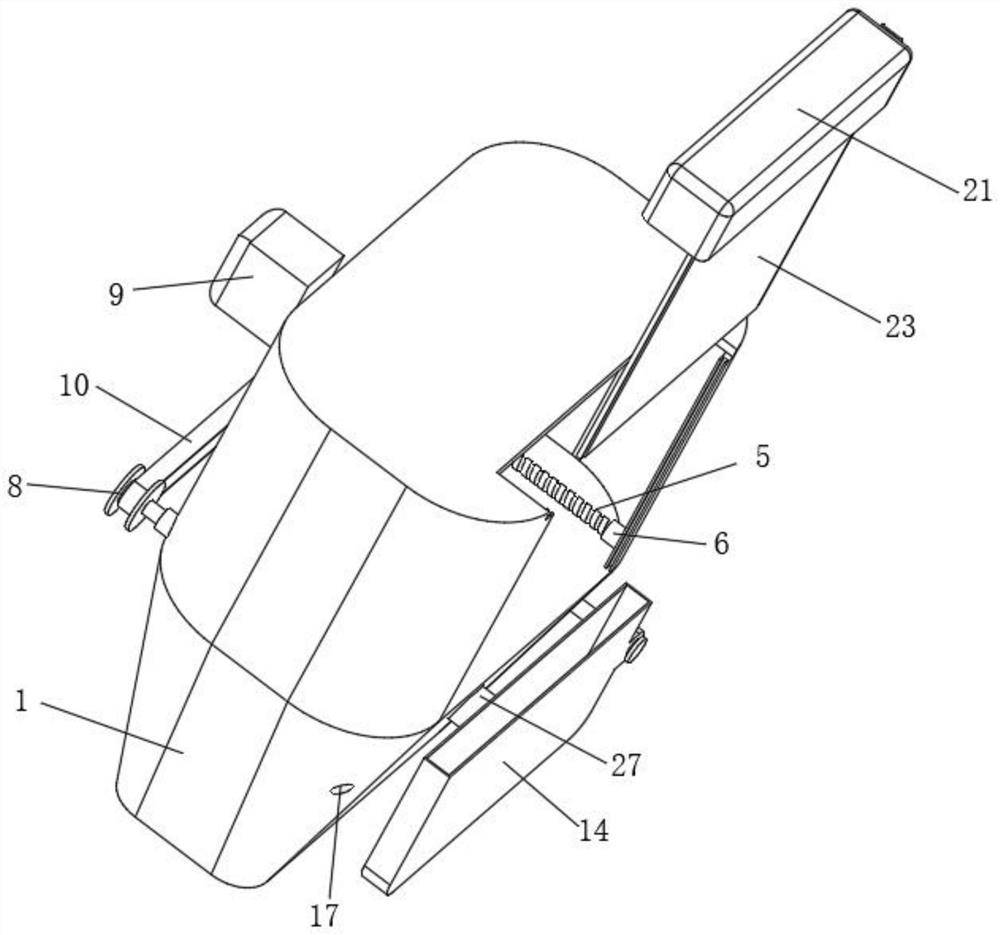

[0027] see figure 1 - Figure 5 , the present invention provides the following technical solutions: a manipulator full-automatic gear table grinding machine includes a machine base 1, a grinding box 2 is fixed on the top of the machine base 1, a grinding motor is arranged in the grinding box 2, and a grinding machine is fixed at the output end of the grinding motor. The disc 3 and the bottom of the grinding box 2 are provided with a hollow groove 4, the machine base 1 is provided with a chip cleaning mechanism, the top of the machine base 1 is provided with a protection mechanism, the protection mechanism is provided with a rolling door mechanism, and the front side of the machine base 1 is provided with a There is a chip storage mechanism, and the chip storage mechanism and the machine base 1 are provided with a limit mechanism.

[0028] In a specific embodiment of the present invention, the entire grinding machine has a reasonable structure, ingenious conception, and flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com