Steel structure end processing device for building

An end treatment, steel structure technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine parts, etc. Improve overall processing efficiency, reduce end processing time, and avoid the effect of grinding disc shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

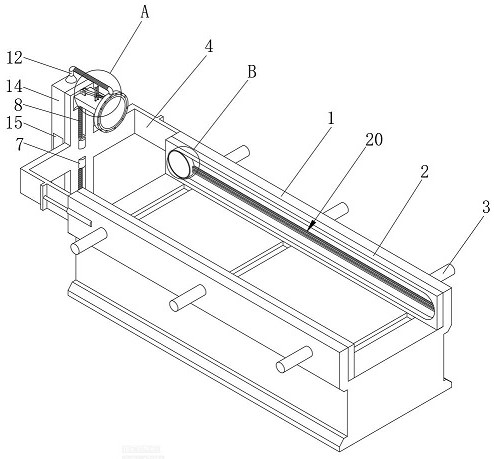

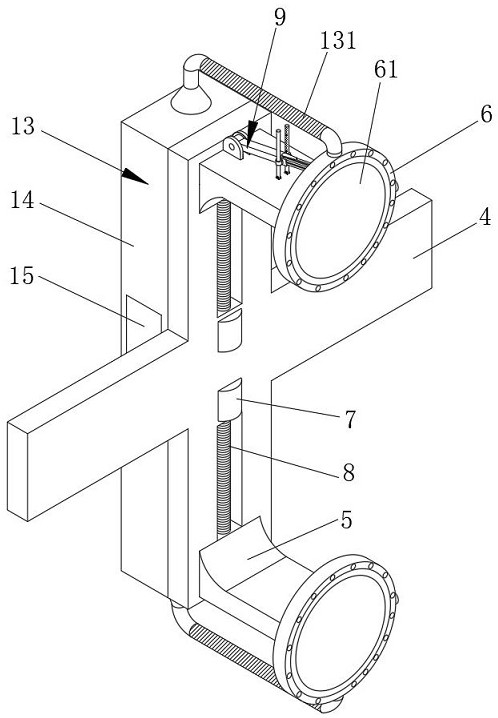

[0032] Embodiment 1: When it is necessary to grind steel structure ends with different inclination angles as required, the present invention provides such figure 1 , figure 2 , image 3 , Figure 5 , Figure 8 , Figure 9 The end treatment device for a steel structure used in a building is shown, which includes an operation table 1, a clamping chamber set on the top of the operation table 1 for the clamping plate 2 to be installed, and a clamping cavity installed on both sides of the operation table 1 for pushing the clamp The hydraulic rod 3 clamped by the tight plate 2, one end of the console 1 is equipped with a cross-shaped fixed plate 4 through the connecting plate, the fixed plate 4 is provided with a channel for the installation plate 5 to install, and the channel is set There is a threaded rod 8 adjusted by the auxiliary mounting plate 5, and an adjusting motor 7 that drives the threaded rod 8 to rotate is installed on the fixed plate 4, so that during the working...

Embodiment 2

[0037] Embodiment 2: when carrying out grinding treatment, the present invention provides as figure 1 , figure 2 , Figure 4 , Figure 5 In the end treatment device for a steel structure used in construction, two mounting plates 5 for the operation panel 6 are installed symmetrically on the fixed plate 4, and an air-collecting structure is arranged on the outer side of the fixed plate 4 13.

[0038] Specifically, the operation panel 6 is provided with a plurality of dust collection holes connected to the gas collection structure 13 on the outer side of the grinding disk 61. The dust collection holes are funnel-shaped, and the funnel-shaped setting can be To improve the overall dust collection effect, the outer side of the operation panel 6 is protrudingly provided with a mounting head, and the mounting head is installed on the gas-collecting structure 13 through the gas-collecting pipe 131, the gas-collecting pipe 131 is a corrugated hose, and several dust-collecting holes...

Embodiment 3

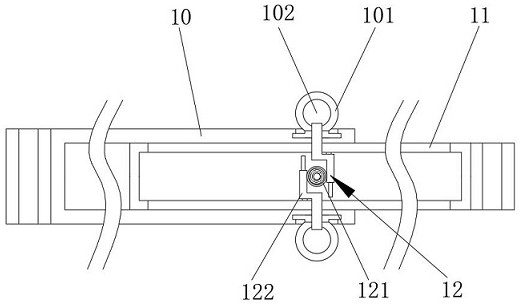

[0043] Embodiment 3: When the steel structure is clamped, the present invention provides such figure 1 , Figure 6 , Figure 7 In the shown end processing device for a steel structure for construction, an oblong cavity is opened on the inner side of the clamping plate 2, and a derusting structure 20 for assisting the grinding of the outer side of the steel structure is installed in the cavity. .

[0044] Specifically, a guide bar 21 is horizontally fixed in the cavity, and the center of the guide bar 21 is provided with an adjustment chamber for the transmission rod 22 to rotate. One end of the guide bar 21 is installed with a rotating motor that drives the drive rod 22 to rotate. The rust structure 20 is sleeved and installed on the guide bar 21 .

[0045] Specifically, the derusting structure 20 includes a fixed plate 23 installed on the guide bar 21 and a derusting plate 24 rotatably arranged on the fixed plate 23, and the derusting structure 20 can rust on the outer edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com