Control system of mechanical arm and test method thereof

A technology for robotic arms and control systems, applied in robotic arms, program-controlled robotic arms, manufacturing tools, etc., which can solve problems affecting the normal operation of robotic arms, unstable control process, and lack of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

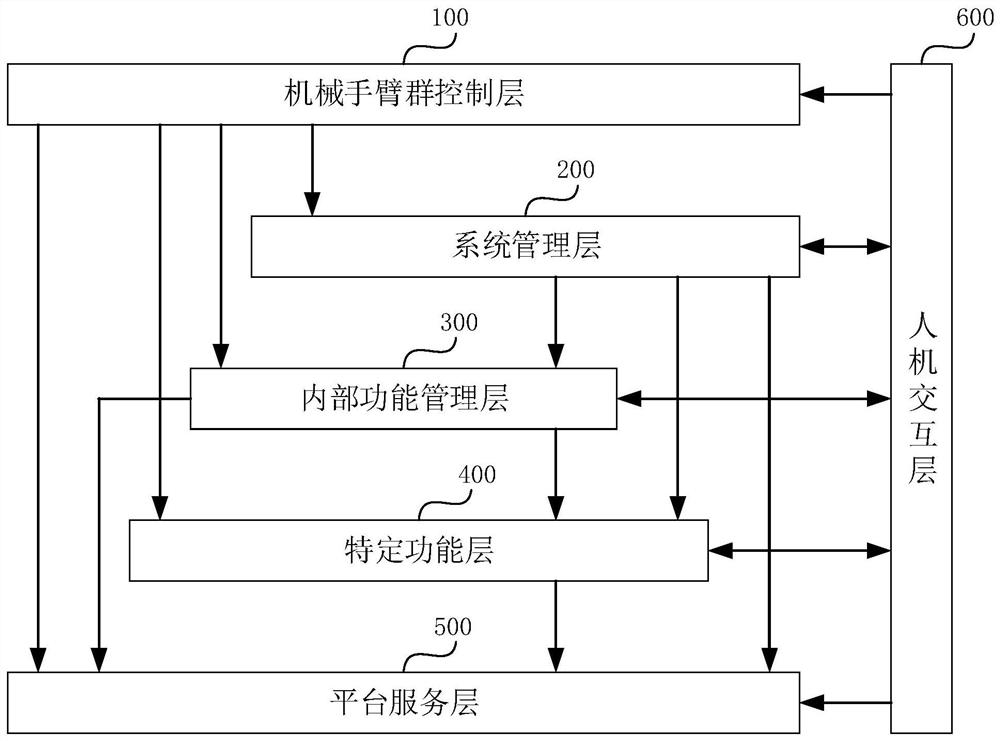

[0023] figure 1 It is a structural block diagram of a control system of a robotic arm provided in Embodiment 1 of the present invention. refer to figure 1 , the control system of the manipulator includes: manipulator group control layer 100, system management layer 200, internal function management layer 300, specific function layer 400, platform service layer 500, and human-computer interaction layer 600; wherein, the manipulator group control layer 100. The system management layer 200, the internal function management layer 300, the specific function layer 400, the platform service layer 500, and the human-computer interaction layer 600 control the mechanical arm through data calls between layers; wherein, the mechanical arm The group control layer 100, the system management layer 200, the internal function management layer 300, the specific function layer 400, and the platform service layer 500 are arranged sequentially from the upper layer to the lower layer; among them, ...

Embodiment 2

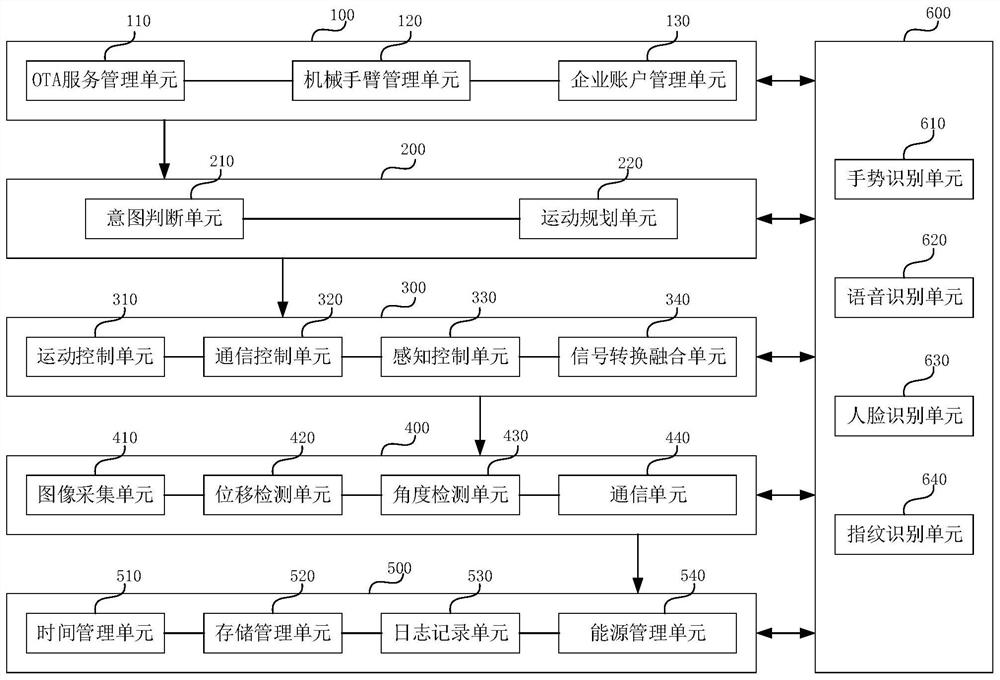

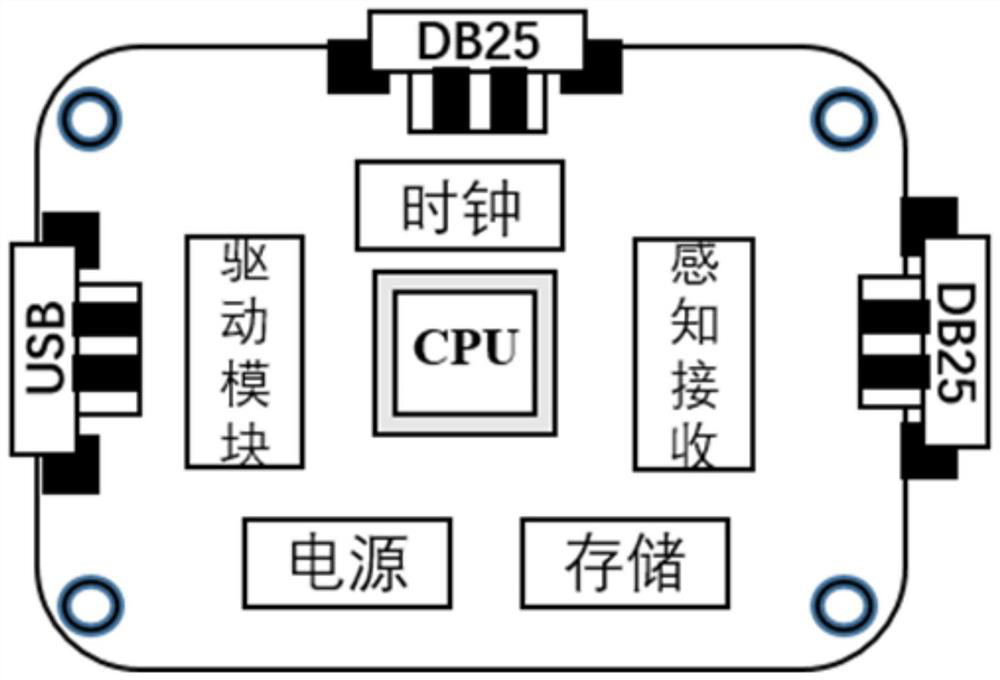

[0029] figure 2 It is a structural block diagram of a control system of a mechanical arm provided in Embodiment 2 of the present invention, image 3 It is a schematic structural diagram of a hardware circuit board provided in Embodiment 2 of the present invention. On the basis of the first embodiment above, optionally, refer to figure 2 , the robot arm group control layer 100 at least includes an OTA service management unit 110, a robot arm management unit 120, and an enterprise account management unit 130, and the OTA service management unit 110, the robot arm management unit 120, and the enterprise account management unit 130 are connected to each other.

[0030] Wherein, the OTA service management unit 110 implements remote control and management of the robotic arm management unit 120 and the enterprise account management unit 130 through cloud technology. The OTA service management unit 110 can call the data of the robotic arm management unit 120 and the enterprise acc...

Embodiment 3

[0047] Figure 4 It is a schematic structural diagram of a test platform provided in Embodiment 3 of the present invention. Embodiment 3 of the present invention provides a test method applied to the control system of the robotic arm described in any embodiment of the present invention, the method includes the following steps:

[0048] Step 1: Based on the traditional platform and adaptive platform of AUTOSAR, the controlled object model and the robot arm perform data and information interaction; among them, the traditional platform, adaptive platform and controlled object model perform time scheduling through the clock.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com