High-purity graphene as well as preparation method and application thereof

A graphene, high-purity technology, applied in graphene, chemical instruments and methods, carbon-silicon compound conductors, etc., to achieve the effects of high conductivity, low cost, and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

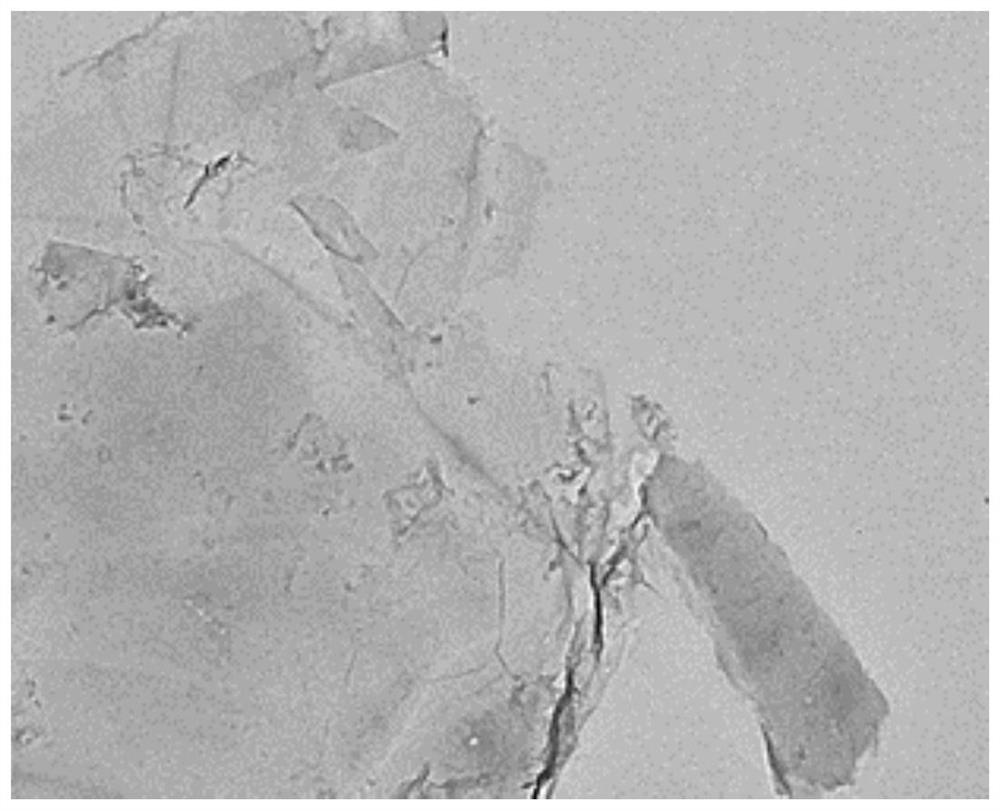

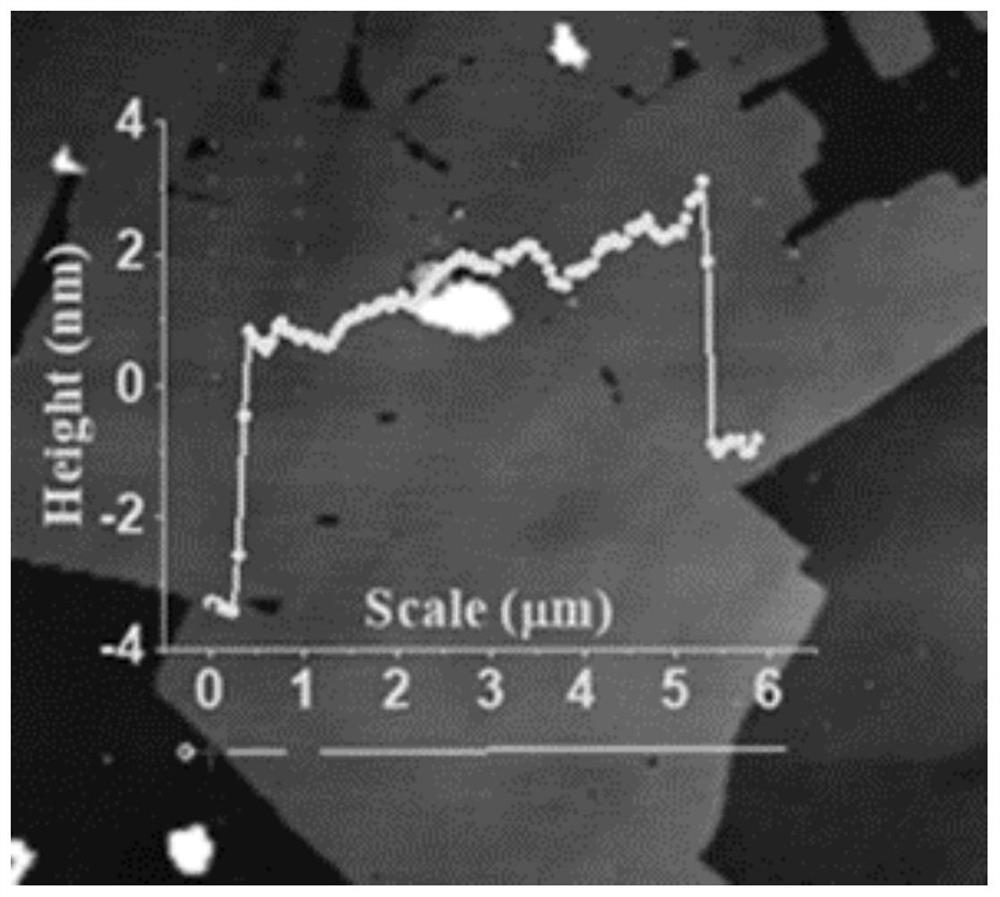

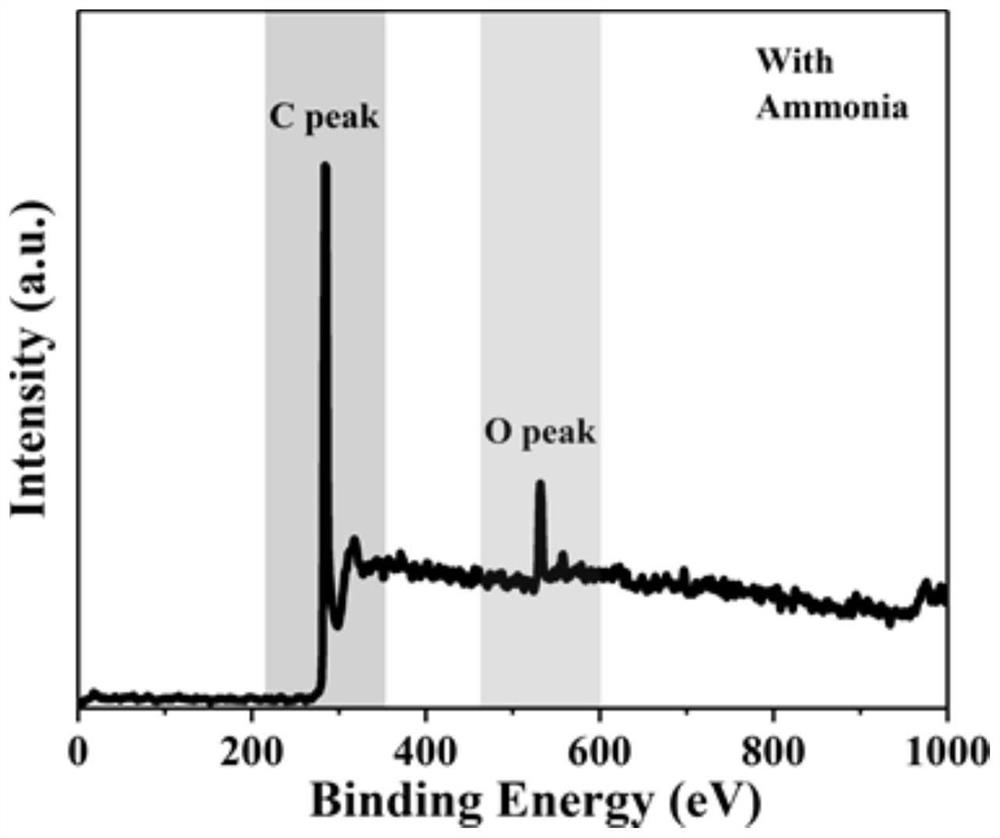

Image

Examples

Embodiment 1

[0034] Preparation method of high purity graphene, comprising the steps of:

[0035] (1) Press the graphite foil to a graphite sheet A having a thickness of 3 mm, as an electrolytic positive electrode; select the a negative electrode of the platinum electrode as electrolysis; the ammonium sulfate is selected into 1.3 mol / L of ammonium sulfate solution B, as an electrolyte, the electrolyte The device is placed at a constant temperature environment at a temperature of 0 ° C, and at a 3V DC voltage, stabilizes for 0.3 h;

[0036] (2) 5 ml of 6 wt% of the tetrabutylammonium sulfate sulfate ammonium sulfate was 13% by weight of the pH of 13 ml of ammonium sulfate, and the mixture was stirred at room temperature (25 ° C) at room temperature (25 ° C). Ultrasound is less than 5 minutes to obtain an alkaline electrolyte C; transfer the electrode of step (1) to the alkaline electrolyte solution C, the voltage is stabilized at 12V, continuously energizing 2 h, at the bottom of the alkaline...

Embodiment 2

[0047] Preparation method of high purity graphene, comprising the steps of:

[0048] (1) Press the graphite foil to a graphite sheet A having a thickness of 2 mm, as an electrolytic positive electrode; select the copolymer of the platinum electrode as an electrolysis; sodium sulfate is selected from 2 mol / L sulfate solution B, as an electrolyte, electrolyte device Placed at a constant temperature environment at 0 ° C, at a DC voltage of 1V, stabilizes for 1 h;

[0049] (2) The pH of the sodium sulfate solution B was added to the sulfate solution B was added to the ammonium sulfate solution B, and the mixture was stirred for 15 minutes at room temperature (25 ° C) at room temperature (25 ° C). Ultrasound is less than 5 minutes to obtain an alkaline electrolyte C; transfer the electrode of step (1) to the alkaline electrolyte solution C, the voltage is stabilized at 10V, continuously transmitting 1.5 h, at the bottom of the alkaline electrolyte C to obtain precipitation D;

[0050...

Embodiment 3

[0060] Preparation method of high purity graphene, comprising the steps of:

[0061] (1) Press the graphite foil to a graphite sheet A having a thickness of 2.5 mm, as an electrolytic positive electrode; select the copolymer of the platinum electrode as an electrolytic electrolysis; the ammonium sulfate is selected into 1.5 mol / L of ammonium sulfate solution B, as an electrolyte, Place the electrolyte device at a constant temperature environment at a constant temperature environment at a 2.7V DC voltage, stable to maintain 3 h;

[0062] (2) The pH of the sulfate solution B was adjacent to the sulfate solution B was added to the ammonium sulfate solution B, and the mixture was stirred at room temperature for 15 minutes, and at room temperature (25 ° C) at room temperature (25 ° C) The 50W power is less than 5 minutes to obtain a basic electrolyte C; transfer the electrode of step (1) to the alkaline electrolyte solution C, the voltage is stabilized at 15V, continuously energizing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com