Safe composting and on-site returning method for solanaceous straw

A technology of solanaceous fruit and straw is applied in the field of safe composting and in-situ returning of solanaceous straw, which can solve the problems of high degree of lignification, environmental pollution, and difficulty in decomposing traditional compost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

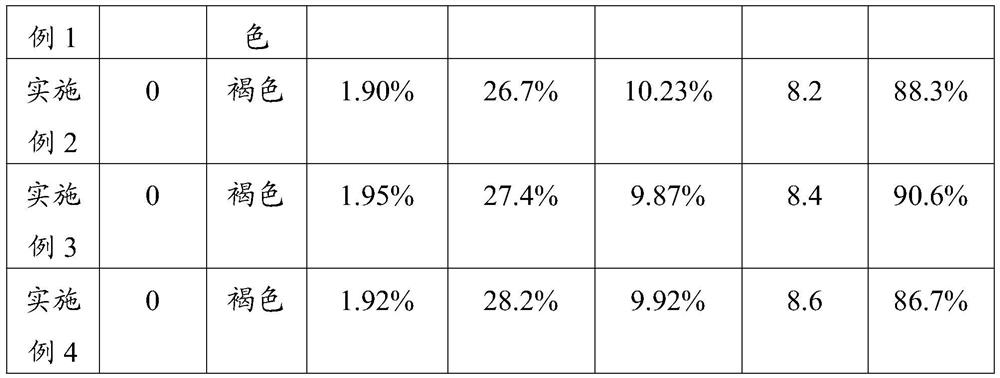

Examples

Embodiment 1

[0020] (1) Dry the tomato vines until the moisture content is about 30%, and use a pulverizer to grind the tomato vines to a length of about 2 cm.

[0021] (2) Tomato vines and duck manure are mixed at a weight ratio of 7:3 to prepare a mixed material. Add 4% magnesium phosphate and 0.1% glucose according to the weight of the mixed material, and then adjust the water content to 60% to 70% with water.

[0022] (3) Carry out the stacking system of stacking, the bottom of the stack is 1.5m, the height is 1m, and the film is covered. Turn over once every 10 days, and turn over 3 times in total.

Embodiment 2

[0024] (1) Dry the tomato vines until the moisture content is about 30%, and use a pulverizer to grind the tomato vines to a length of about 2 cm.

[0025] (2) Mix the pulverized tomato vines with 1% quicklime, and stack them in a circular pile with a height of 1.5m.

[0026] (3) Sprinkle water evenly according to 5% of tomato weight, then cover with thicker plastic film, compact and seal with soil around, and pre-stack for 5 days.

[0027] (4) Pre-composted tomato vines and duck manure were mixed at a weight ratio of 7:3 to prepare a mixed material. Add 4% magnesium phosphate, 0.1% glucose, and 1% wood vinegar according to the weight of the mixed material, and then adjust the water content to about 65% with water.

[0028] (5) Carry out stacking of stacked materials, between 1.5m at the bottom of the stack, with a height of 1m, and covered with film. Turn over once every 10 days, and turn over 3 times in total.

[0029] (6) The composted and decomposed materials are return...

Embodiment 3

[0031] (1) Dry the tomato vines until the moisture content is about 30%, and use a pulverizer to grind the tomato vines to a length of about 2 cm.

[0032] (2) Mix the pulverized tomato vines with 1% quicklime, and stack them in a circular pile with a height of 1.5m.

[0033] (3) Sprinkle water evenly according to 5% of tomato weight, then cover with thicker plastic film, compact and seal with soil around, and pre-stack for 5 days.

[0034] (4) Pre-composted tomato vines and duck manure were mixed at a weight ratio of 7:3 to prepare a mixed material. Add 4% magnesium phosphate, 0.1% glucose, 1% wood vinegar, and 1% enzyme according to the weight of the mixed material, and then adjust the water content to about 65% with water.

[0035] (5) Carry out stacking of stacked materials, between 1.5m at the bottom of the stack, with a height of 1m, and covered with film. Turn over once every 10 days, and turn over 3 times in total.

[0036] (6) The composted and decomposed materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com