Composition for improving yellowing resistance of naphthenic rubber oil

A technology of naphthenic rubber oil and composition, applied in the field of rubber processing, can solve the problems of low volatility, poor photothermal stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

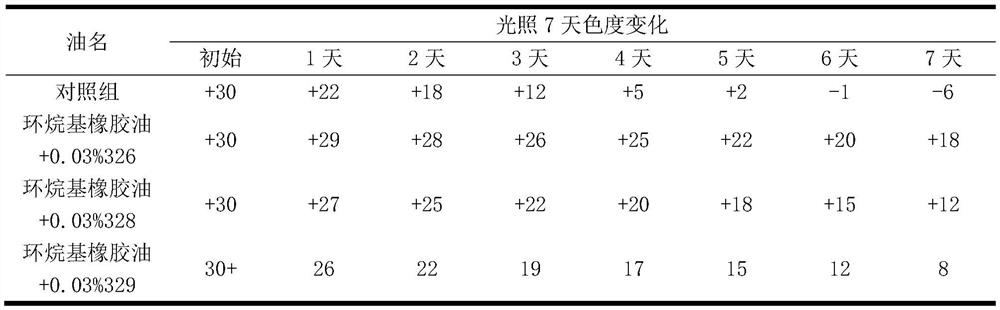

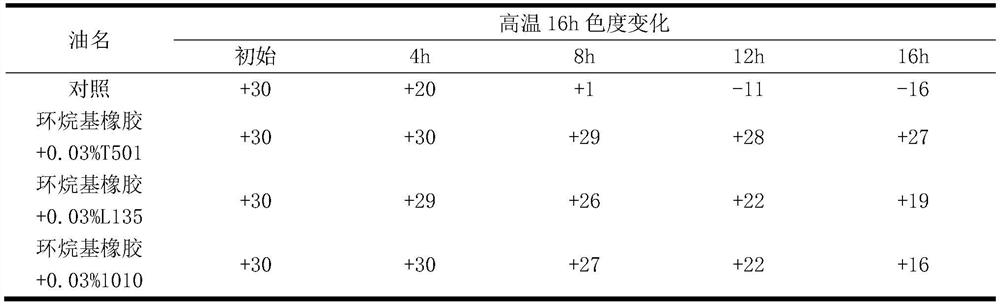

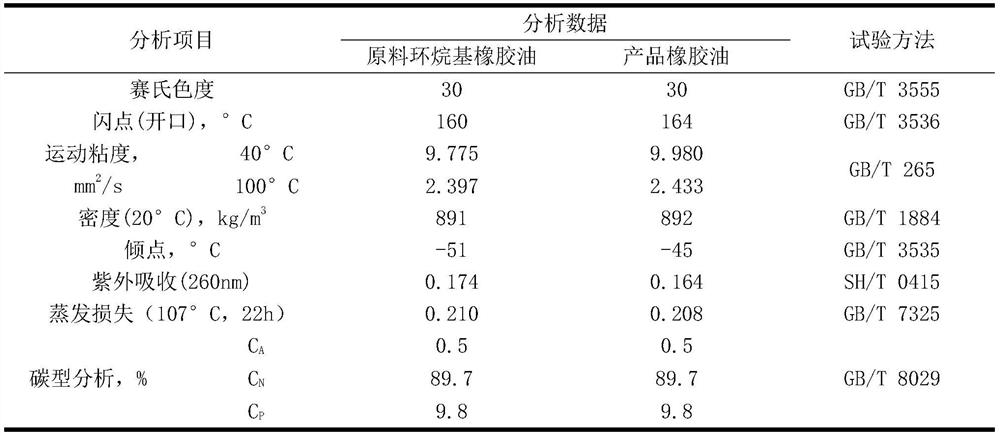

Examples

Embodiment 1

[0045] A kind of preparation method of rubber oil, concrete steps are as follows:

[0046] (1) First mix 1g 2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole and 0.5g 2,6-di-tert-butyl p- The methyl phenol is mixed evenly to obtain the composition;

[0047] (2) Then, under the condition of 100° C., take 0.06 g of the composition and add it into 100 g of naphthenic rubber oil, and stir and mix evenly.

Embodiment 2

[0049] A kind of preparation method of rubber oil, concrete steps are as follows:

[0050](1) First mix 1g 2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole and 2g 2,6-di-tert-butyl p-methyl The base phenol is mixed uniformly to obtain a composition;

[0051] (2) Then, under the condition of 90° C., take 0.12 g of the composition and add it into 100 g of naphthenic rubber oil, and stir and mix evenly.

Embodiment 3

[0053] A kind of preparation method of rubber oil, concrete steps are as follows:

[0054] (1) First mix 1g 2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole and 1g 2,6-di-tert-butyl p-methyl The base phenol is mixed uniformly to obtain a composition;

[0055] (2) Then, under the condition of 95° C., take 0.09 g of the composition and add it into 100 g of naphthenic rubber oil, and stir and mix evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com