Production method for reducing content of levulinic acid in caramel color in common method

A production method, levulinic acid technology, applied in the production field of levulinic acid content, can solve problems such as respiratory allergies, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

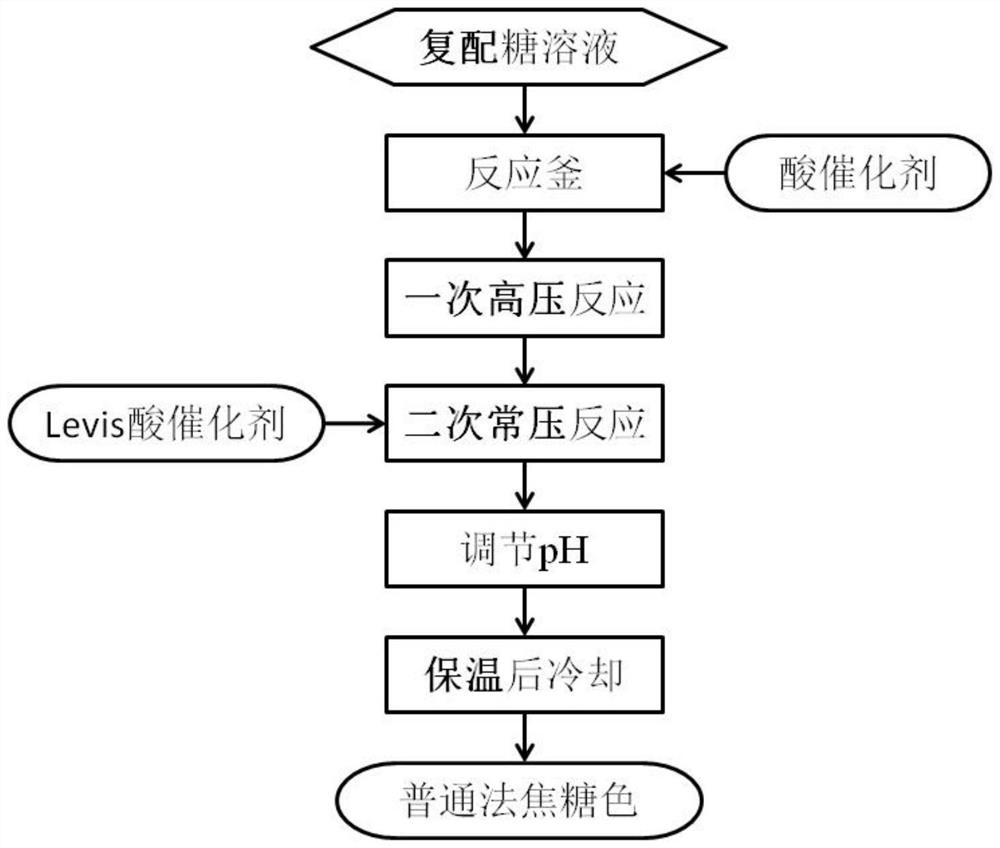

Method used

Image

Examples

Embodiment 1

[0026] Choose a high-pressure reactor with a volume of 25L, take 7.5kg of solid F55 fructose syrup, 6kg of solid glucose syrup and 1.5kg of solid white sugar solution into the reactor, mix well to form a dry basis of more than 80% Then add acid catalyst (food-grade sulfuric acid, the mass of active ingredients accounts for 0.2‰ of the solid content of the compound sugar solution), and carry out a reaction under semi-closed conditions. The reaction temperature is 150°C and the heating rate is 30°C. ℃ / h, pressure 0.05MPa, coking reaction until the color rate is 5500, then add Lewis acid (ferric chloride, the solid content accounts for 0.1‰ of the solid content of the compound sugar solution) and acid catalyst (food grade citric acid, The mass of the active ingredient accounts for 0.2‰ of the solid mass of the compound sugar solution), and the secondary reaction is carried out under normal pressure, the reaction temperature is 135°C, and the reaction color rate is 15000EBC. After ...

Embodiment 2

[0028] Select a high-pressure reactor with a volume of 25L, add F55 fructose syrup with 6kg of solids, glucose syrup with 6kg of solids, and white sugar solution with 3kg of solids into the reactor, and mix evenly to form a compound with a dry basis of more than 80%. Add sugar solution, then add acid catalyst (food grade sulfuric acid, the active ingredient mass accounts for 0.1‰ of the solid content of the compound sugar solution), and carry out a reaction under semi-closed conditions, the reaction temperature is 150 °C, and the heating rate is 50 °C / h, the pressure is 0.050MPa, and the coking reaction reaches a color rate of 5500, then add Lewis acid (aluminum chloride, the solid content accounts for 0.5‰ of the solid content of the compound sugar solution) and acid catalyst (food grade citric acid, active ingredient The mass accounts for 0.1‰ of the solid content of the compound sugar solution), and the secondary reaction is carried out under normal pressure. The reaction t...

Embodiment 3

[0030] Select a high-pressure reactor with a volume of 25L, take 10kg of solid F55 fructose syrup, 2.5kg of solid glucose syrup and 2.5kg of solid white sugar solution into the reactor, mix well to form a dry basis of more than 80% The compound sugar solution of compound sugar solution, then add acid catalyst (food grade citric acid, active ingredient quality accounts for 0.4‰ of compound sugar solution solid matter mass), carry out a reaction under semi-closed condition, reaction temperature is 150 ℃, and heating rate is 20°C / h, pressure 0.05MPa, coking reaction until the color rate is 4500, then add Lewis acid (ferric chloride, the solid content accounts for 0.2‰ of the solid content of the compound sugar solution) and acid catalyst (food grade sulfuric acid, The mass of the active ingredient accounts for 0.1‰ of the solid mass of the compound sugar solution), and the secondary reaction is carried out under normal pressure, the reaction temperature is 140°C, and the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com