Vertical butt joint type vehicle end liquid cooling connecting device, battery mounting part and electric vehicle

A connection device and electric vehicle technology, applied in electric vehicles, electric vehicle charging technology, vehicle components, etc., can solve problems such as imperfect liquid tightness, leakage, dripping, etc., achieve simple and efficient installation and connection process, ensure sealing, The effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

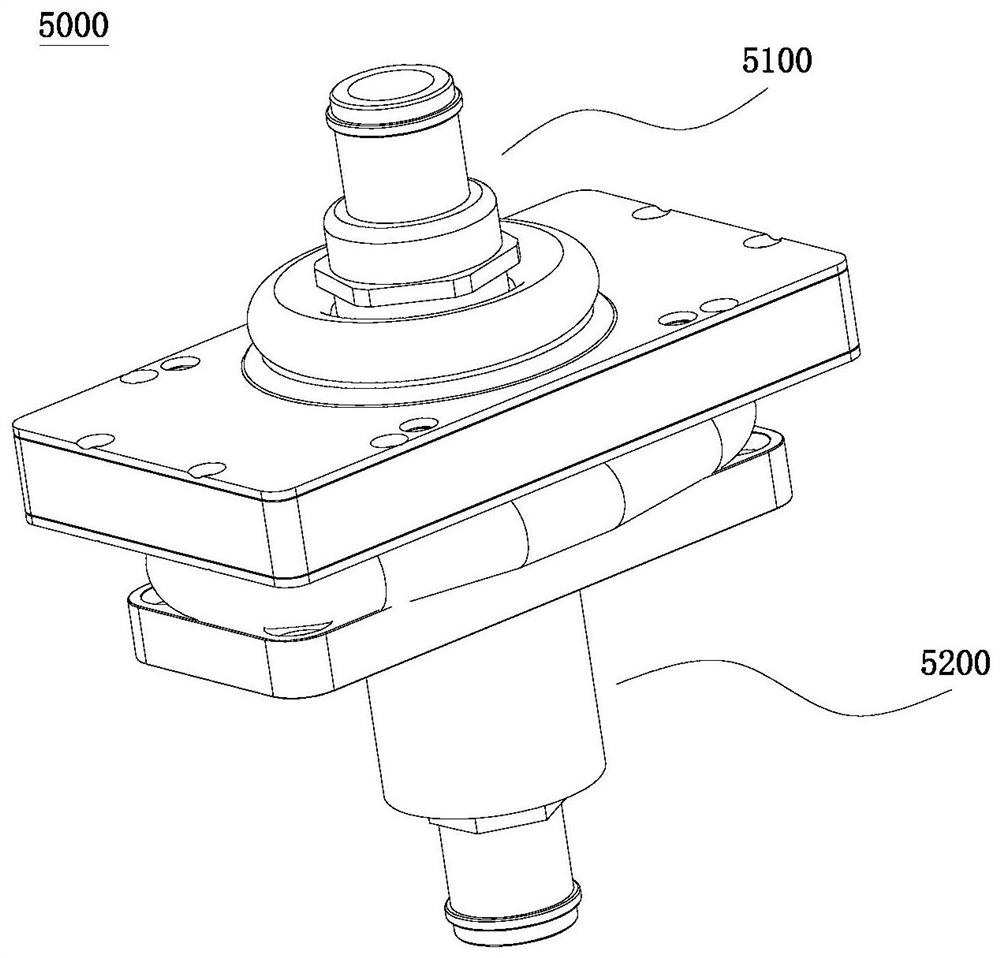

[0045] Such as Figures 1 to 3 As shown, Embodiment 1 discloses a liquid cooling connection assembly 5000, the liquid cooling connection assembly 5000 is used between the liquid supply device and the liquid cooling pipeline, and the liquid cooling connection assembly 5000 realizes the connection between the liquid supply device and the liquid cooling pipeline. The communication between the liquid cooling pipelines allows the cooling liquid in the liquid supply device to flow into the liquid cooling pipelines and return to the liquid supply device, thereby realizing heat exchange in the area where the liquid cooling pipelines are set.

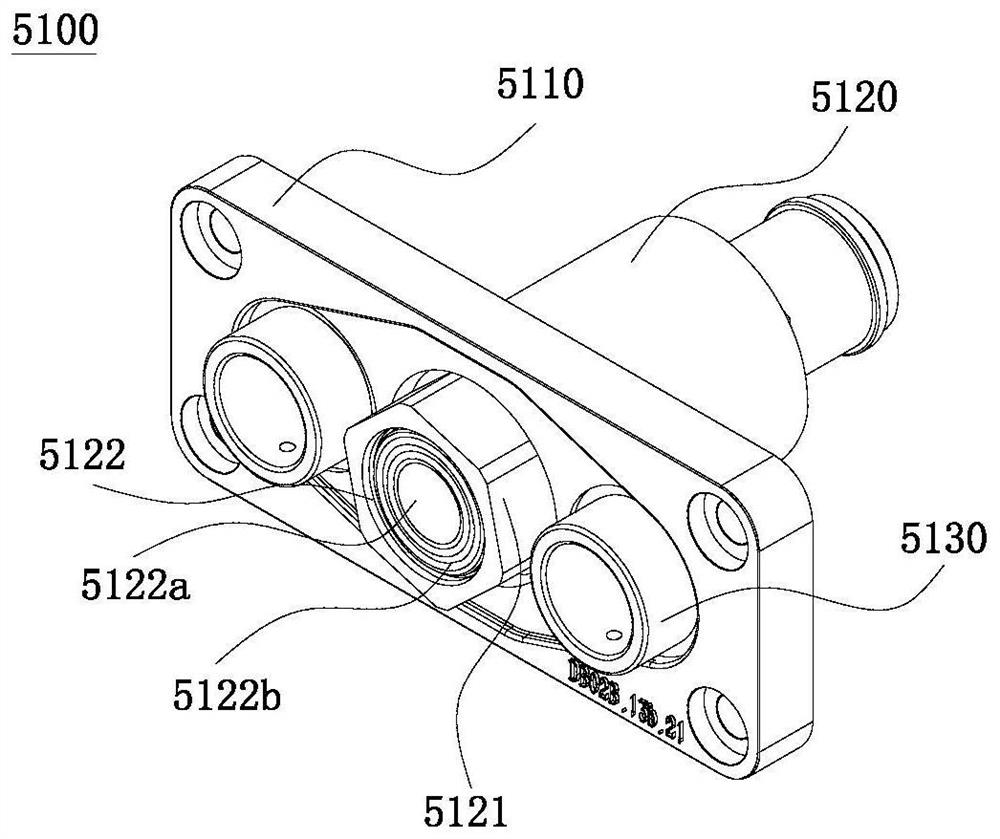

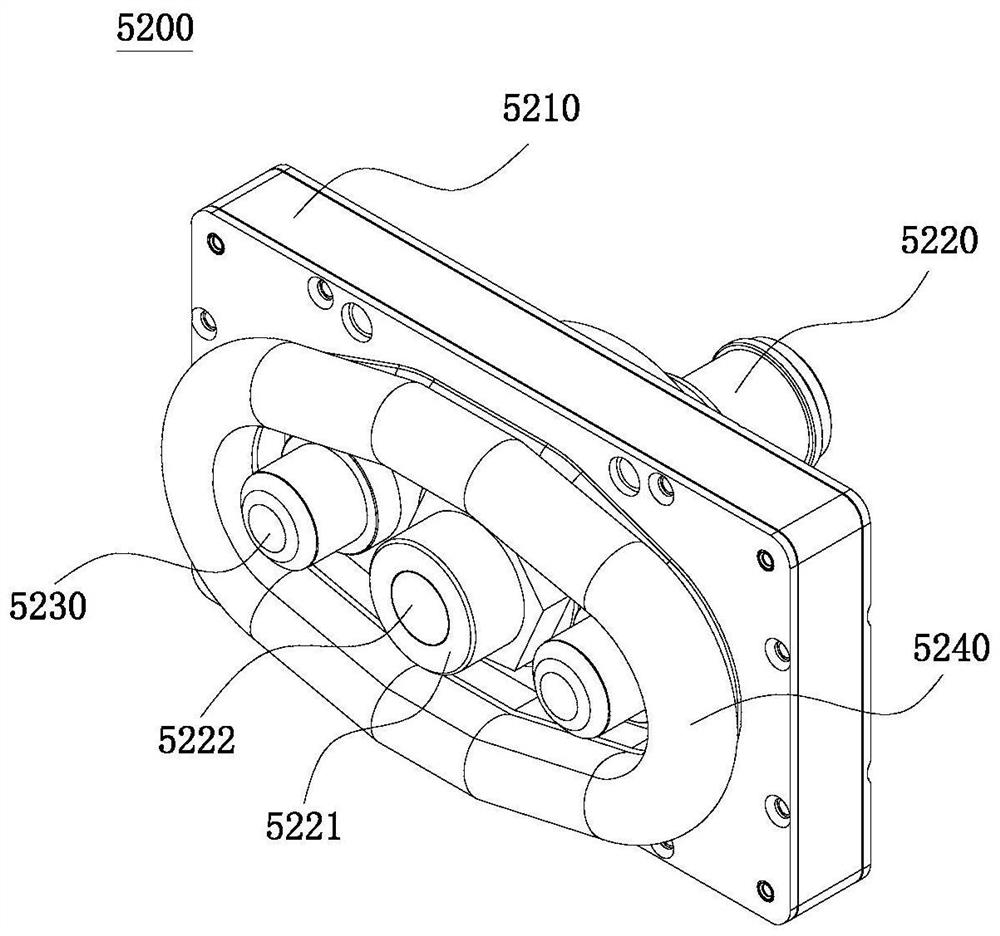

[0046]Specifically, the liquid cooling connection assembly 5000 includes a first liquid cooling connection device 5100 and a second liquid cooling connection device 5200, the first liquid cooling connection device 5100 is used in conjunction with the second liquid cooling connection device 5200, and one of them is provided as The connecting join...

Embodiment 2

[0067] Such as Figure 4 As shown, the second embodiment discloses a battery mounting part 7000, which is used in an electric vehicle and is used to install the battery pack 6000 on the electric vehicle. The battery mounting part 7000 has the first liquid cooling connection device 5100 or the second liquid cooling connection device 5200 described in Embodiment 1 above, and the first liquid cooling connection device 5100 or the second liquid cooling connection device 5200 is a vertical docking type The vehicle end liquid cooling connection device is provided on the battery installation part 7000 . In the vertical butt joint vehicle end liquid cooling connection device, the first mounting seat 5110 and the second mounting seat 5210 as well as the first connecting valve 5120 and the second connecting valve 5220 are collectively referred to as the mounting seat and the connecting valve.

[0068] When the battery mounting part 7000 is connected to the battery pack 6000, the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com