Battery cover gum waste recovery device

A waste recycling and battery cover technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve problems such as waste of graphite cover glue, and achieve the effects of improving quality, reducing production costs and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

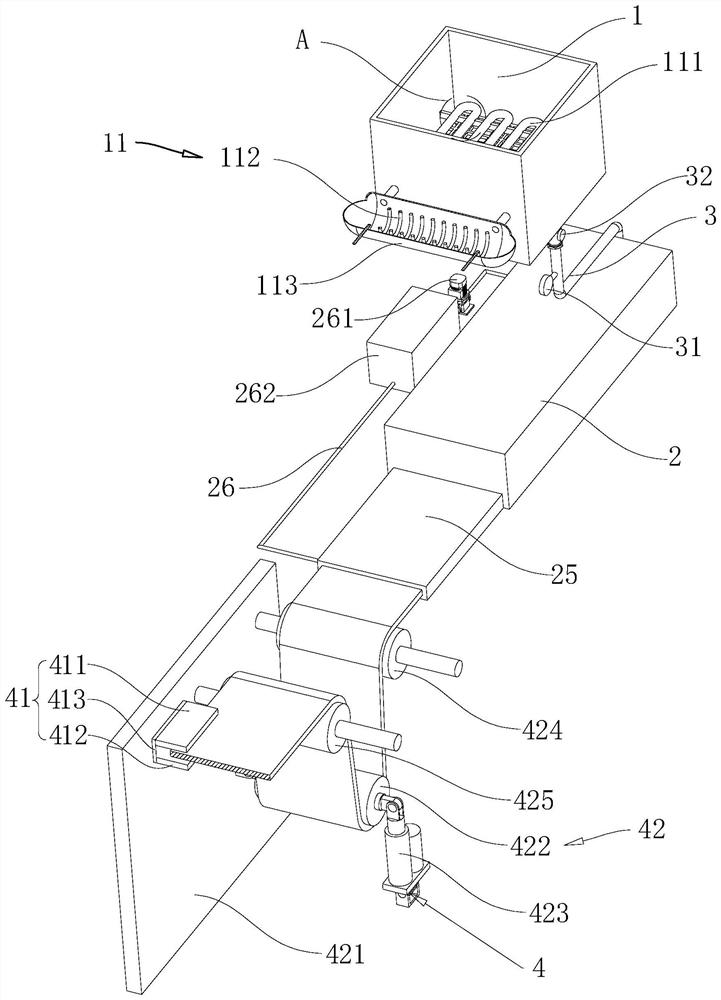

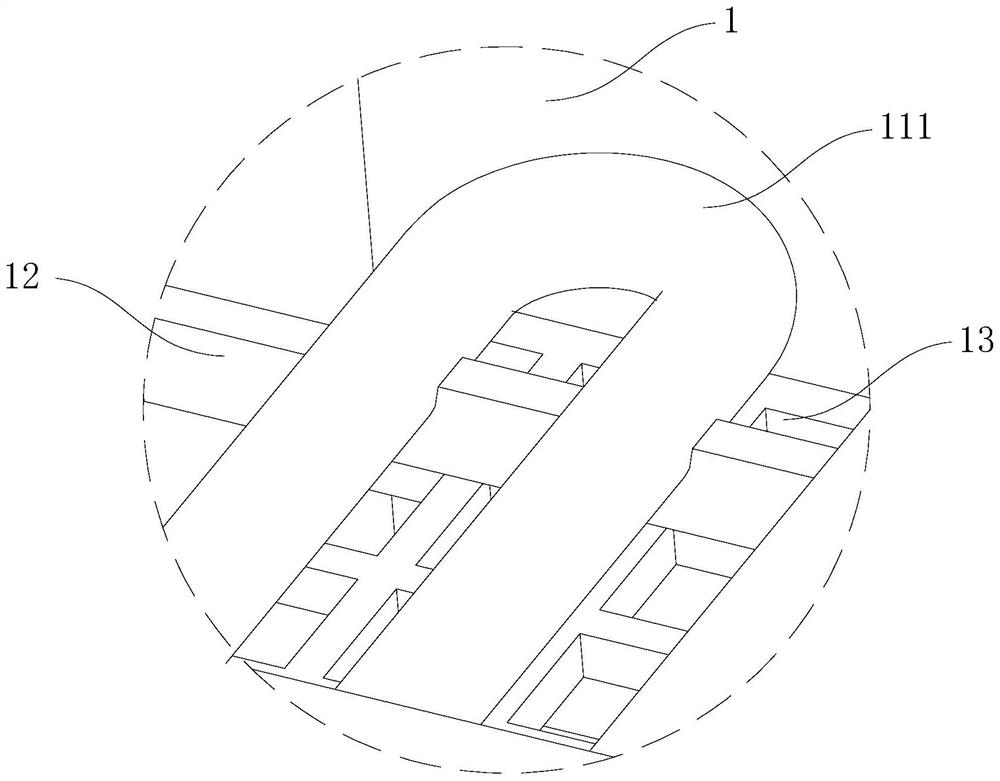

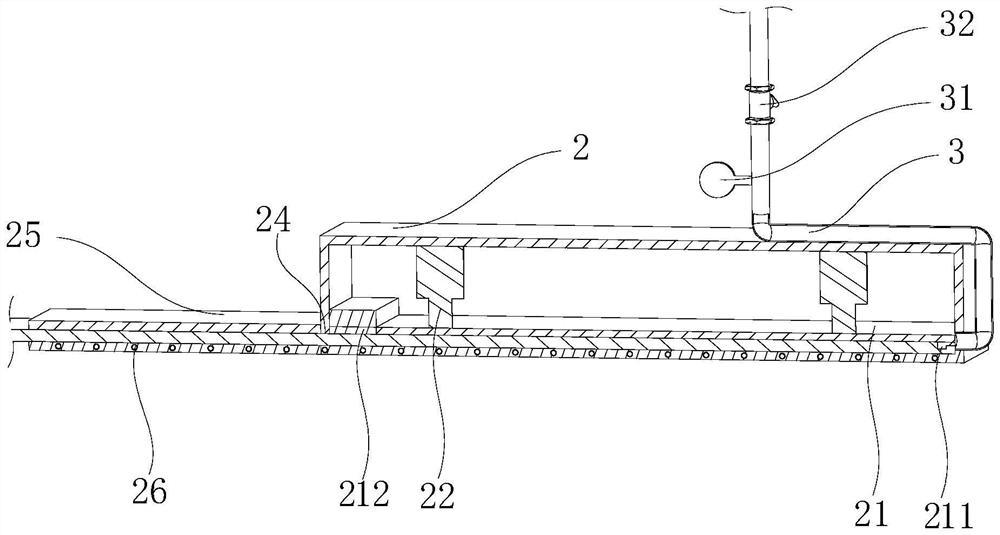

[0037] Attached to the following Figure 1-4 This application will be described in further detail.

[0038] The embodiment of the present application discloses a battery cover adhesive waste recycling device. refer to figure 1 , the recovery device includes a hot melt box 1 and a forming box 2 . The hot-melt box 1 is used to heat and melt the corner waste generated in the production process of the battery cover adhesive, and then inject the melted graphite adhesive into the molding box 2 for cooling and shaping, so that the graphite backing becomes in the molding box 2. Continuous sheet rubber strips, and then the graphite rubber strips are drawn to the production line for processing.

[0039] The graphite-backed adhesive edge waste is heated and melted through the hot melt box 1, then cooled and shaped and returned to the production line to continue the production of battery cover adhesive. The graphite-backed adhesive edge and corner waste is recycled, reducing waste Pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com