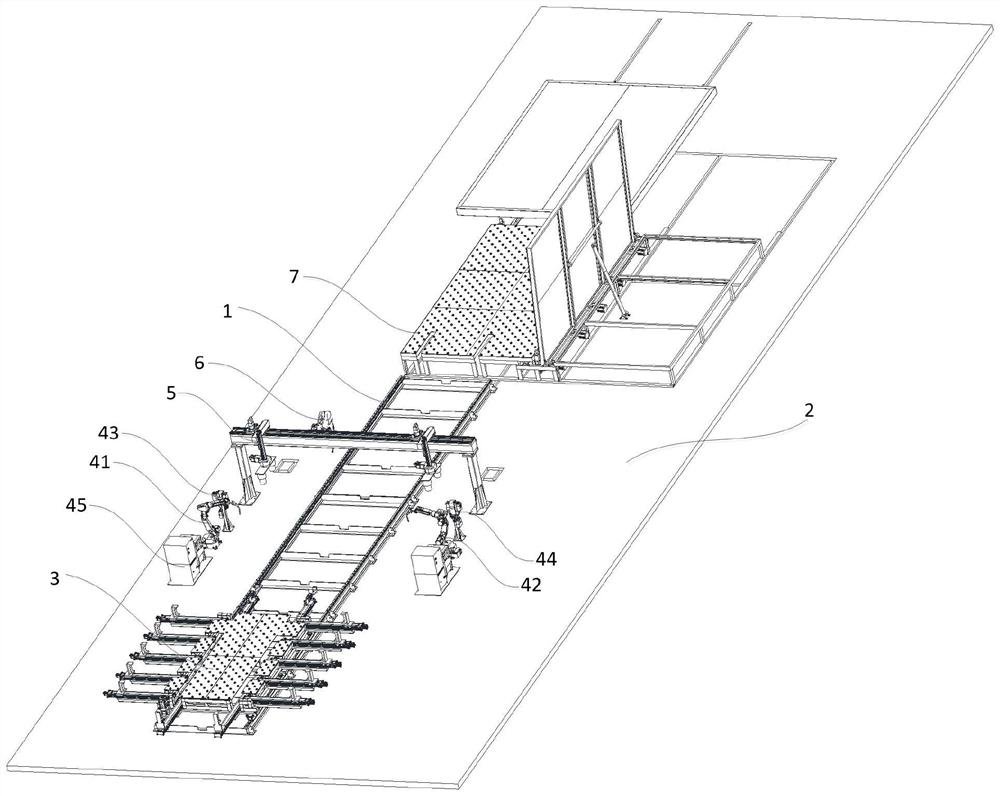

Cold storage door production line

A technology for cold storage doors and production lines, applied in auxiliary devices, coatings, conveyors, etc., can solve the problems of low processing accuracy, low efficiency, low degree of automation, etc., and achieve the effect of improving processing efficiency and processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

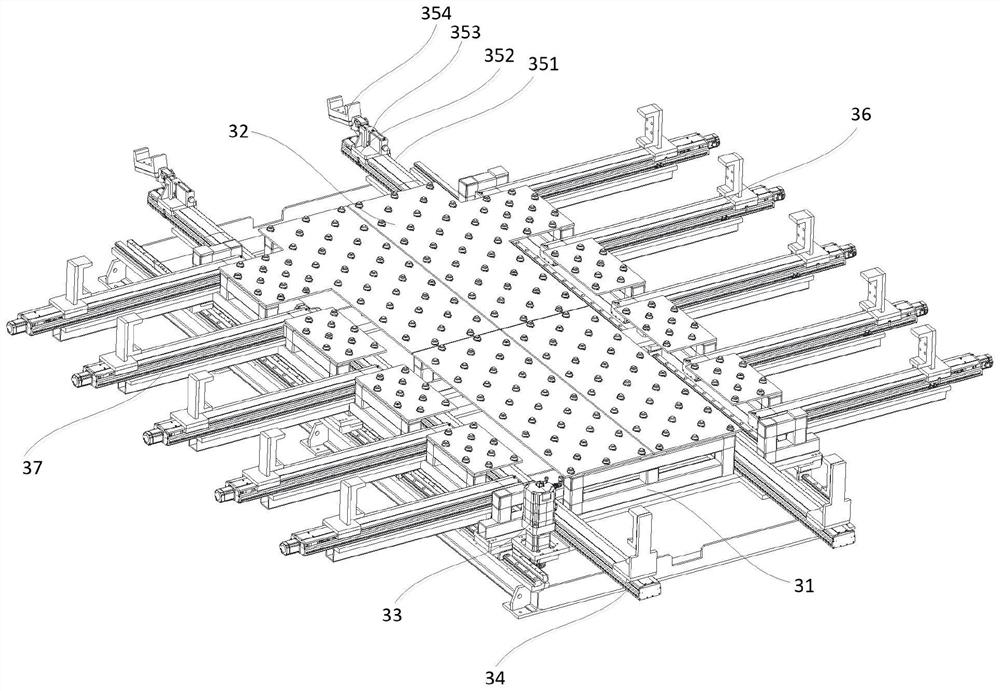

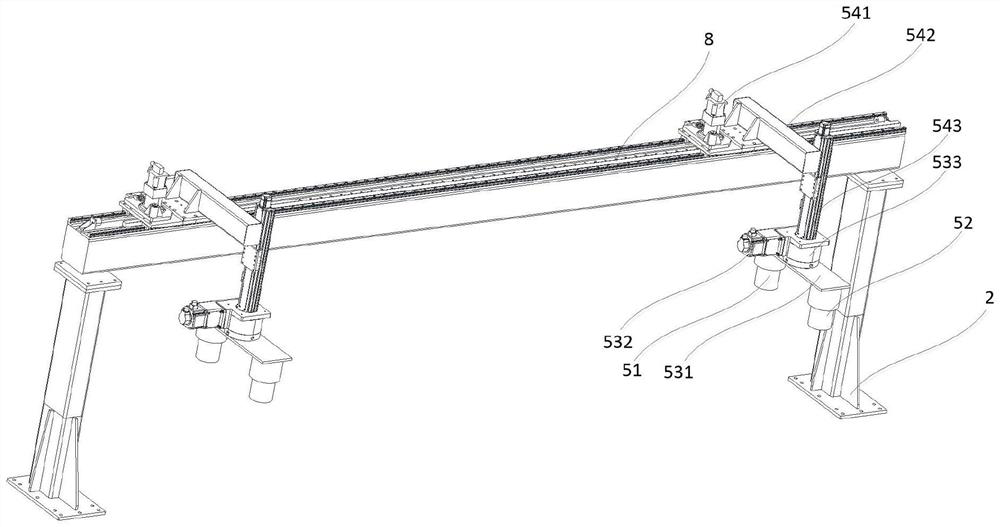

[0023] In order to make the objects, features, and advantages of the present invention, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Several embodiments of the present invention are given in the drawings. However, the present invention can be implemented in many different forms, is not limited to the embodiments described herein.

[0024] In the present invention, the terms "mount", "connected", "linked", "fixed", such as the term "mount", "connected", "linked", "fixed", may be a fixed connection, or a detachable connection may be a fixed connection. Or integrally joined; may be mechanical connections, or electrical connection; may be directly connected, or indirectly connected by an intermediate medium, which can be internally internally in the two elements. The specific meaning of the above terms in the present invention can be understood in terms of specific cases. The term "first", "second" is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap