Flash dry granular glaze, flash dry granular polished ceramic plate and preparation method of flash dry granular glaze and flash dry granular polished ceramic plate

A dry-grain glaze and ceramic plate technology, applied in the field of ceramic building materials, can solve the problems of erosion damage of lamella structure, opaque and light transmittance of crystals, easy precipitation and radioactivity risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

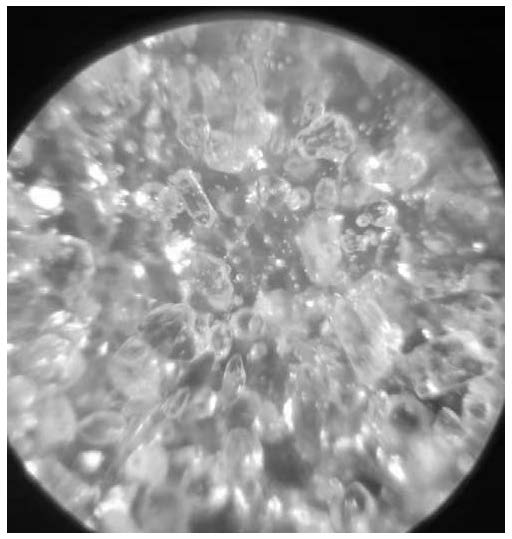

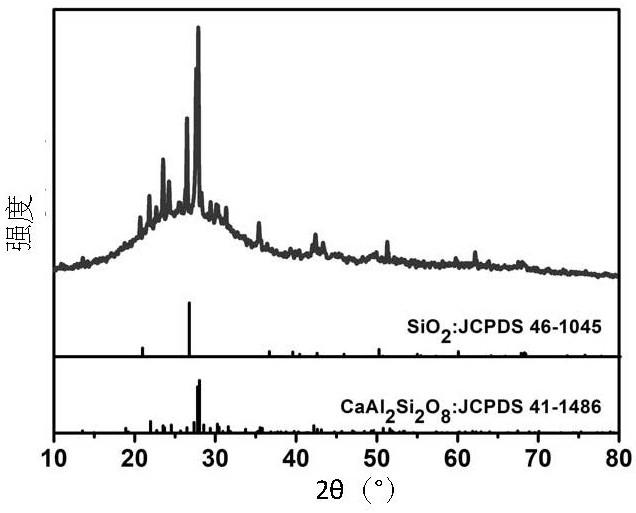

[0044] The preparation method of the flashing dry grain polished ceramic plate of the present invention adopts the method of spontaneous crystallization instead of adding the flashing phase, and uses high-calcium dry grains and low-temperature transparent dry grains in combination. During the high-temperature firing process, the glaze melt forms Uniformly dispersed locally high calcium liquid phase. Uniform dispersion means that the high calcium liquid phase is evenly distributed in the glaze layer. Partial refers to the formation of a liquid phase with high calcium content after the high-calcium dry granules are melted, and the liquid phase is not miscible with the low-temperature transparent dry granules, that is, the high-calcium liquid phase has not been diluted or homogenized. With the help of the interfacial interaction between high-calcium dry granules and low-temperature transparent dry granules and the nucleating agent present in the flash dry granule glaze to induce ...

Embodiment 1

[0049] The preparation method of the flash dry grain polished ceramic plate comprises the following steps:

[0050] 1. Pressing the green body powder to obtain a ceramic green body. The ceramic body is sent to a drying kiln for drying.

[0051] 2. Apply glaze on the surface of the dried ceramic body. The chemical composition of the surface glaze includes: by mass percentage, loss on ignition 6.2%, SiO 2 48%, Al 2 O3 26%, Fe 2 o 3 0.08%, TiO 2 0.12%, CaO 5%, MgO 3.3%, K 2 O3.5%, Na 2 O 0.2%, ZrO 2 8%. The specific gravity of the surface glaze is 1.46, and the glaze amount is 700g / m 2 .

[0052] 3. Ink-jet printing design decorative patterns on the surface of the glazed ceramic body.

[0053] 4. Prepare the glitter dry grain glaze slurry. Mix 45 parts of low-temperature transparent dry granules, 4 parts of printing powder, 35 parts of glue, 20 parts of high-calcium dry granules, and 8 parts of water to prepare glitter dry granule glaze for use. The chemical com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com