Preparation method of real stone paint primer emulsion with good tear resistance and alkali resistance

A technology of tear resistance and alkali resistance, used in primers, coatings, etc., can solve the problems of poor tear resistance and alkali resistance, improve molecular weight and crosslink density, and improve the degree of branching. , the effect of good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

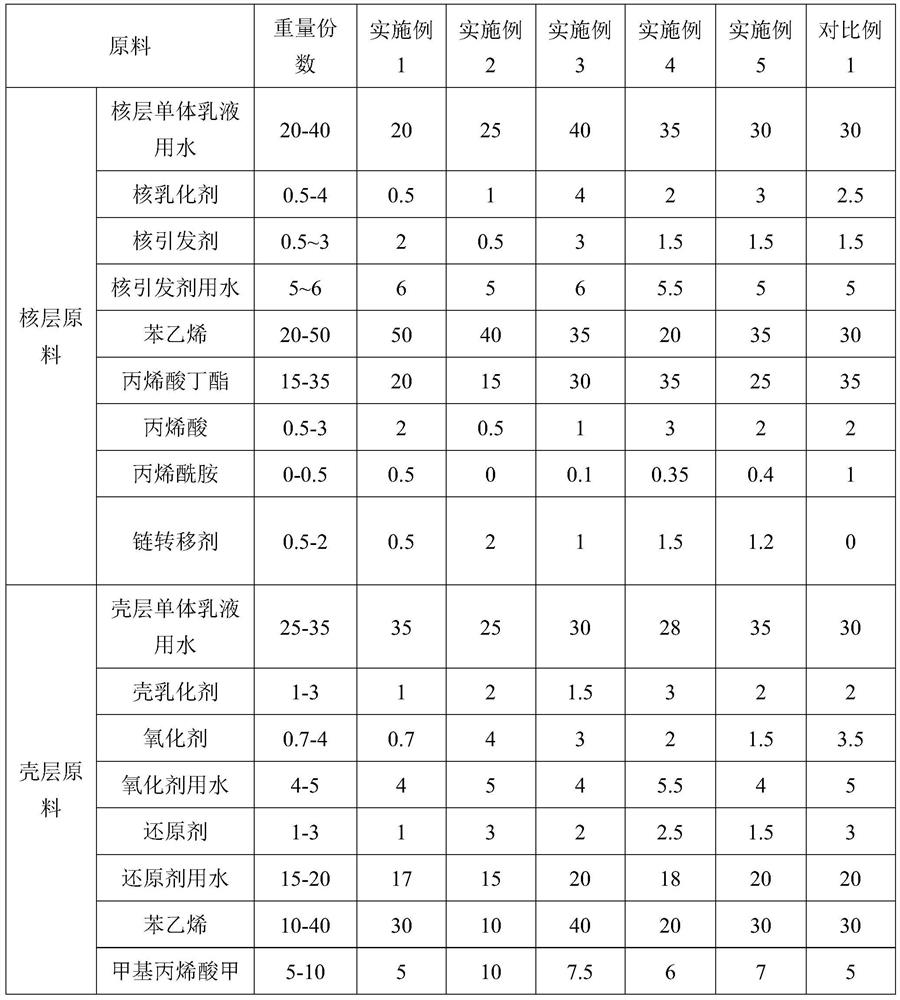

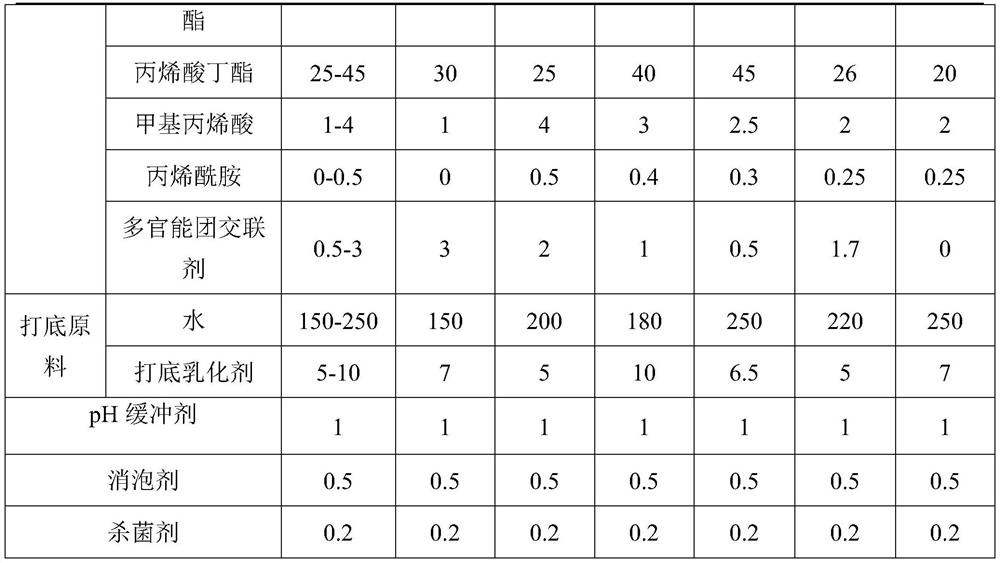

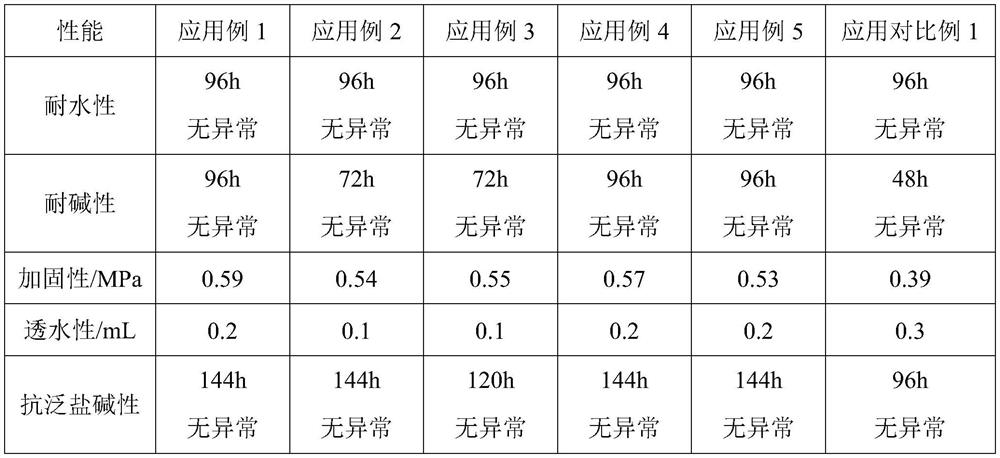

Embodiment 1

[0030] A real stone paint primer emulsion with good tear resistance and alkali resistance, the raw materials of the primer emulsion include core layer raw materials, shell layer raw materials, and primer materials,

[0031] The core layer raw material includes the following components by weight: 20 parts of water for the core layer monomer emulsion, 0.5 parts of nuclear emulsifier, 2 parts of nuclear initiator, 6 parts of water for nuclear initiator, 50 parts of styrene, 20 parts of butyl acrylate, 2 parts of acrylic acid, 0.5 part of acrylamide, 0.5 part of chain transfer agent; nuclear initiator is sodium persulfate; chain transfer agent is n-dodecyl mercaptan;

[0032] Shell raw materials include the following components by weight: 35 parts of water for shell monomer emulsion, 1 part of shell emulsifier, 0.7 parts of oxidant, 4 parts of water for oxidant, 4 parts of reducing agent, 17 parts of water for reducing agent, and 30 parts of styrene , 5 parts of methyl methacrylat...

Embodiment 2

[0043] A real stone paint primer emulsion with good tear resistance and alkali resistance, the raw materials of the primer emulsion include core layer raw materials, shell layer raw materials, and primer materials,

[0044] The core layer raw material includes the following components by weight: 25 parts of water for the core layer monomer emulsion, 1 part of nuclear emulsifier, 0.5 parts of nuclear initiator, 5 parts of water for nuclear initiator, 40 parts of styrene, 20 parts of butyl acrylate, 2 parts of acrylic acid, 2 parts of chain transfer agent; nuclear initiator is sodium persulfate; chain transfer agent is n-dodecyl mercaptan;

[0045] Shell raw materials include the following components by weight: 25 parts of water for shell monomer emulsion, 2 parts of shell emulsifier, 4 parts of oxidant, 5 parts of water for oxidant, 3 parts of reducing agent, 15 parts of water for reducing agent, and 10 parts of styrene , 10 parts of methyl methacrylate, 25 parts of butyl acryl...

Embodiment 3

[0056] A real stone paint primer emulsion with good tear resistance and alkali resistance, the raw materials of the primer emulsion include core layer raw materials, shell layer raw materials, and primer materials,

[0057] The core layer raw material includes the following components by weight: 40 parts of water for the core layer monomer emulsion, 4 parts of nuclear emulsifier, 3 parts of nuclear initiator, 6 parts of water for nuclear initiator, 35 parts of styrene, 30 parts of butyl acrylate, 1 part of acrylic acid, 0.1 part of acrylamide, 1 part of chain transfer agent; the nuclear initiator is sodium persulfate; the chain transfer agent is n-dodecyl mercaptan;

[0058] Shell raw materials include the following components by weight: 30 parts of water for shell monomer emulsion, 1.5 parts of shell emulsifier, 3 parts of oxidant, 4 parts of water for oxidant, 2 parts of reducing agent, 20 parts of water for reducing agent, and 40 parts of styrene , 7.5 parts of methyl metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com