Anti-drawing self-resetting composite shock insulation support

A seismic-isolating bearing and self-resetting technology, applied in earthquake-proofing, building components, buildings, etc., can solve the problems of large repair cost after earthquake, weak tensile capacity of rubber seismic-isolating bearing, and limited development, etc. Improved recoverability, good self-reset capability, reduced cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

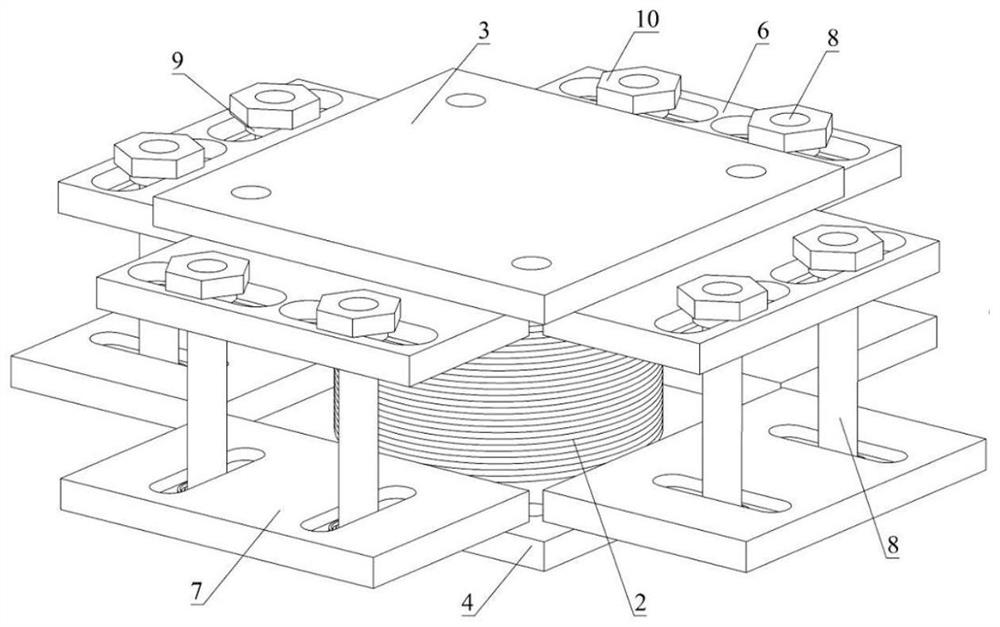

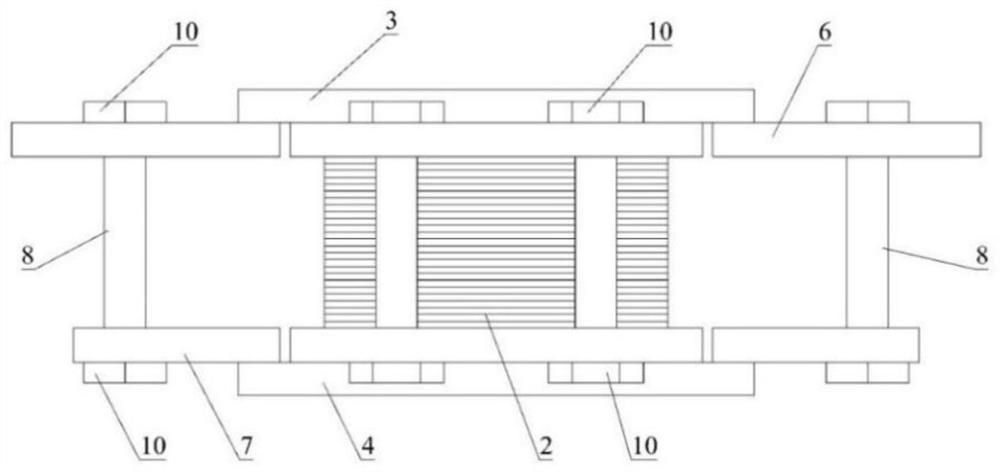

[0021] see Figure 1-8 , the present embodiment discloses a pullout-resistant self-resetting composite shock-isolation bearing, which comprises a shock-isolation bearing composed of a lead core 1, a rubber shock-isolating pad 2, an upper bearing steel plate 3, and a lower bearing steel plate 4, and is arranged on an isolation Anti-pullout self-resetting mechanism 5 around the shock bearing.

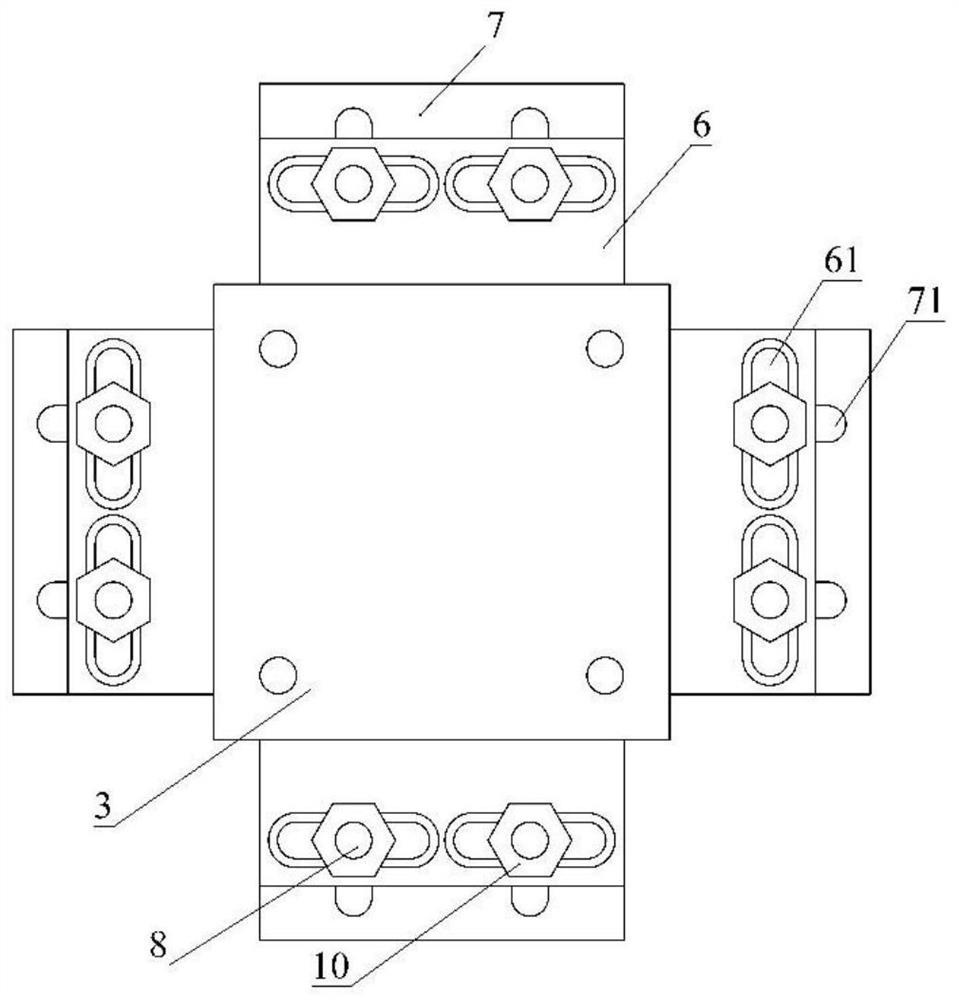

[0022] see Figure 4 , The anti-pullout self-resetting mechanism 5 includes an upper connecting plate 6 , a lower connecting plate 7 and a superelastic shape memory alloy screw 8 . The upper connecting plate 6 is fixed to the upper supporting steel plate 3 by welding or bolting, and the lower connecting plate 7 is fixed to the lower supporting steel plate 4 by welding or bolting. The upper connecting plate 6 is provided with parallel oblong holes 61 parallel to the sideline, and the lower connecting plate 7 is provided with vertical oblong holes 71 perpendicular to the sideline. The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com