Textile dyeing process

A technology of textiles and crafts, applied in the field of textile dyeing technology, which can solve the problems of fabric and textile damage, increase the cost of dyeing technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

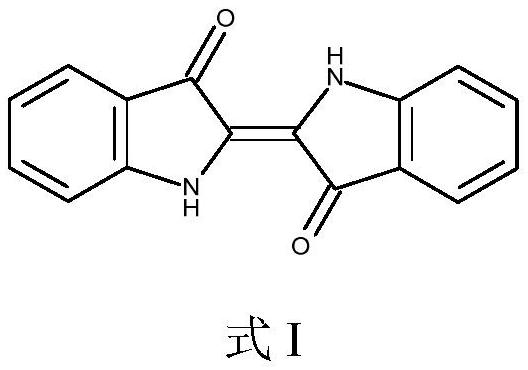

[0092] According to an embodiment, when eg the oxidative enzyme is mFMO and the cofactor regeneration enzyme is PTDH, the step of hydroxylating indole or indole derivatives to obtain indoxyl or indoxyl derivatives may be performed using the fusion enzyme PTDH-mFMO.

[0093] According to an embodiment, when for example the reductase is AzoA and the cofactor regenerating enzyme is PTDH, the step of converting indoxyl or indoxyl derivatives into leuco indoxyl or the leuco form of indoxyl derivatives may be performed using a fusion enzyme PTDH -AzoA.

[0094] For example, a PTDH-AzoA fusion enzyme can have the following sequence:

[0095] MGSSHHHHHHSSGLVPRGSHMLPKLVITHRVHEEILQLLAPHCELITNQTDSTLTREEILRRCRDAQAMMAFMPDRVDADFLQACPELRVIGCALKGFDNFDVDACTARGVWLTFVPDLLTVPTAELAIGLAVGLGRHLRAADAFVRSGKFRGWQPRFYGTGLDNATVGFLGMGAIGLAMADRLQGWGATLQYHARKALDTQTEQRLGLRQVACSELFASSDFILLALPLNADTLHLVNAELLALVRPGALLVNPCRGSVVDEAAVLAALERGQLGGYAADVFEMEDWARADRPQQIDPALLAHPNTLFTPHIGSAVRAVRLEIERCAAQNILQALAGERPINAVNRL...

Embodiment 1

[0239] Materials and methods

[0240] Indigo dyeing of cotton belts was carried out according to the process of the invention using the fusion enzymes PTDH-mFMO (oxidase mFMO fused to cofactor regenerating enzyme PTDH) and PTDH-AzoA (reductase AzoA fused to cofactor regenerating enzyme PTDH).

[0241] The cotton tape is hand sewn from several pieces of cotton cloth, the final size is 2x 20cm.

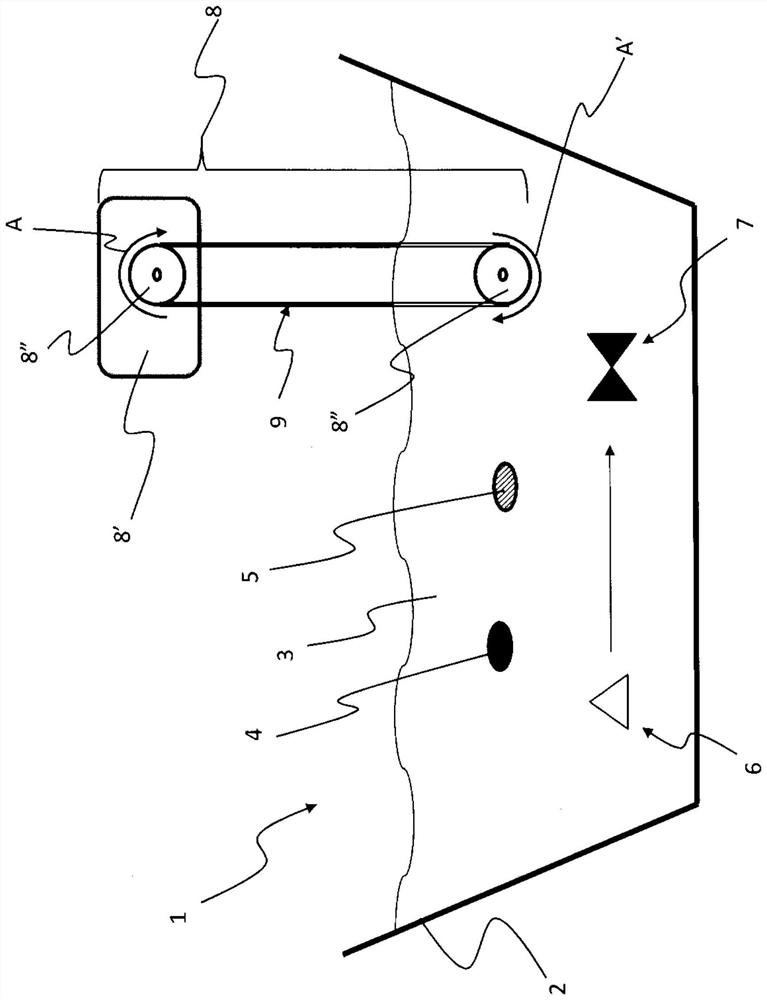

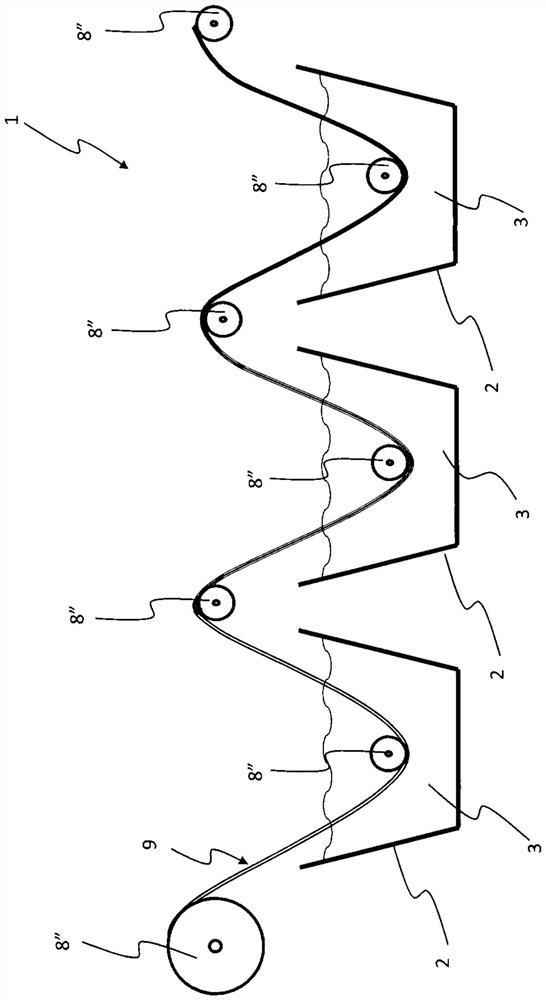

[0242] The apparatus for this experiment is based on figure 1 The schematic drawing and configuration. In particular, the device 8 for circulation or alternate immersion (submersion) and removal of textiles in the reaction mixture comprises a peristaltic pump as motor 8' with a head adapted to be configured as a roller 8" for immersion in the reaction mixture The swivel motion is provided by a cotton tape in the center (immersion 2 cm).

[0243] The cotton belt is rotated by the power of the peristaltic pump, which rotates the cotton cloth in and out of the reaction mixture. Thus,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com