Self-cleaning method of surface cleaning machine

A surface cleaning and self-cleaning technology, used in cleaning machinery, robot cleaning machines, cleaning equipment, etc., can solve problems such as odor, inability to automatically clean sewage suction ports and sewage suction channels, and poor customer experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

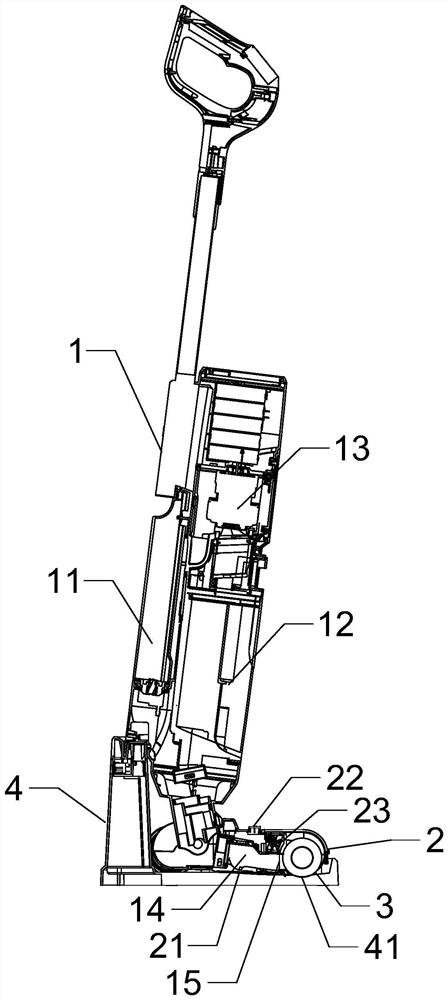

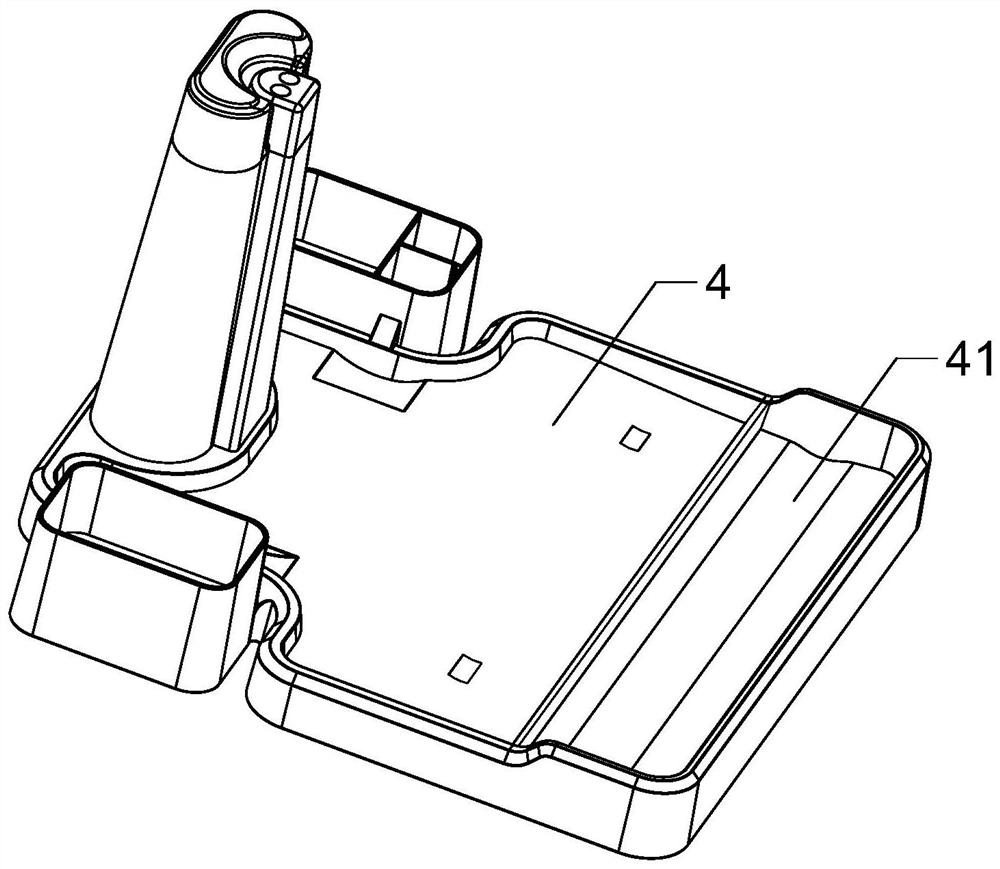

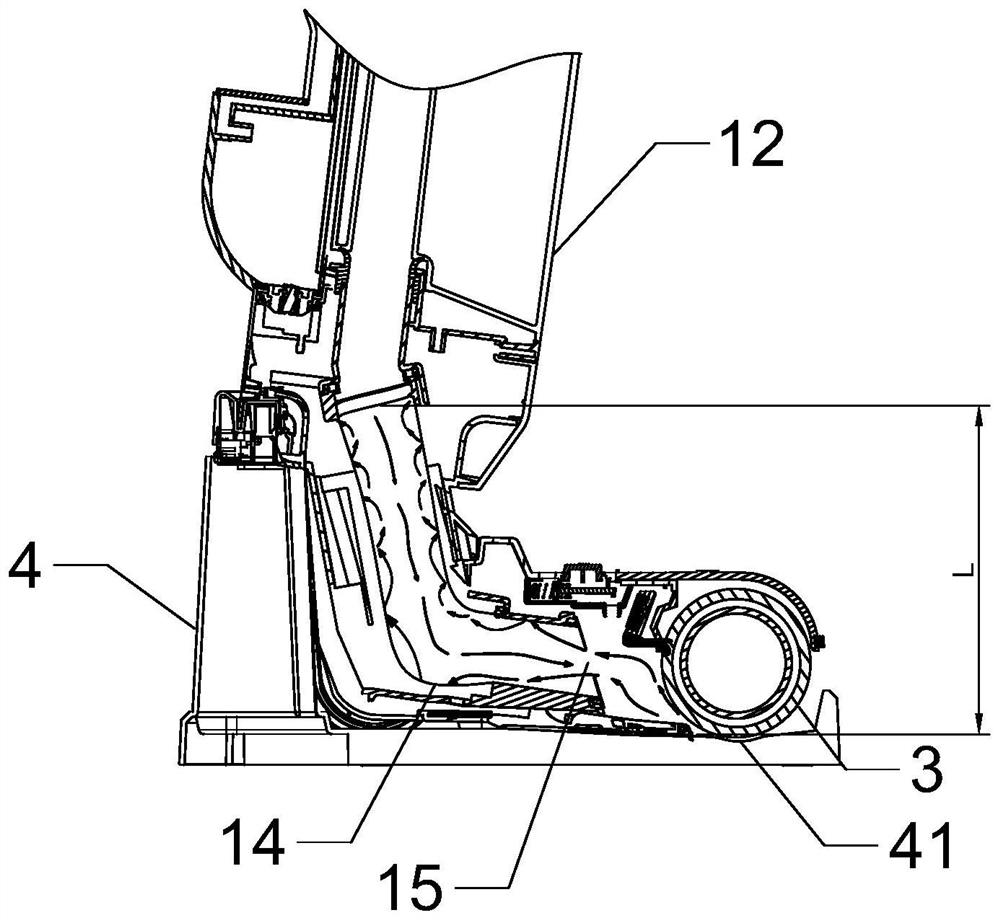

[0043] The invention provides a surface cleaning machine and a cleaning seat 4, such as figure 1 As shown, the surface cleaning machine includes a fuselage 1 and a cleaning assembly 2 hinged with the fuselage 1. The fuselage 1 is provided with a water tank 11, a dirt bucket 12 and a dirt suction motor 13. The cleaning assembly 2 includes a frame 21, The driving motor 24 arranged on the frame, the cleaning roller 3 arranged at the bottom of the frame 21 and the machine cover 22 covered on the frame 21, the frame 21 is provided with a dirt suction channel connected with the dirt bucket 12 14. The dirt suction port 15 of the dirt suction channel 14 is set toward and close to the cleaning roller 3, and the cover 22 is also provided with a water spray port 23, and the cleaning roller 3 is driven to rotate by a driving motor (not shown in the figure), During automatic cleaning, the surface cleaning machine is placed on the cleaning seat 4, and the cleaning seat is provided with a cl...

Embodiment 2

[0055] The difference between the present embodiment and the first embodiment is that the self-cleaning method further includes a step D—a sewage suction and air-drying stage after cleaning the dirt suction channels.

[0056]In this embodiment, the length of the dirt suction channel of the surface cleaning machine is 15cm, the suction power of the dirt suction motor changes stepwise, and the suction power P1 of the dirt suction motor is between 0.3P and 0.4P Under the effect of the change of the suction power waveform of the sewage suction motor, the rising height of the cleaning liquid in the sewage suction channel changes between 0.5L and 0.7L. Since the length L of the dirt suction channel in this embodiment is 15cm, it cooperates with the suction power of the dirt suction motor to switch between 0.3P and 0.4P, so that the cleaning liquid can effectively enter the dirt suction channel. The suction power is under the action of the stepped waveform, and flows up and down in t...

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 is that the self-cleaning method also includes step E—a rinsing stage.

[0066] In this embodiment, the length of the dirt suction channel of the surface cleaner is 20cm, the suction power of the dirt suction motor changes sinusoidally, and the suction power P1 of the dirt suction motor varies between 0.35P and 0.45P , under the action of the suction power waveform change of the dirt suction motor, the rising height of the cleaning liquid in the dirt suction channel varies between 0.6L and 0.8L. Since the length L of the sewage suction channel in this embodiment is 20cm, the sewage suction channel is relatively long, and it cooperates with the sewage suction motor whose suction power changes sinusoidally between 0.35P and 0.45P, so that the cleaning liquid can effectively Enter the sewage suction channel and flow up and down in the sewage suction channel. The height of the cleaning liquid rising in the sewage sucti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com