Fireproof material with alternate multi-layer structure and preparation method of fireproof material

A fireproof material, multi-layer structure technology, applied in the field of fireproof materials, to achieve the effect of excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

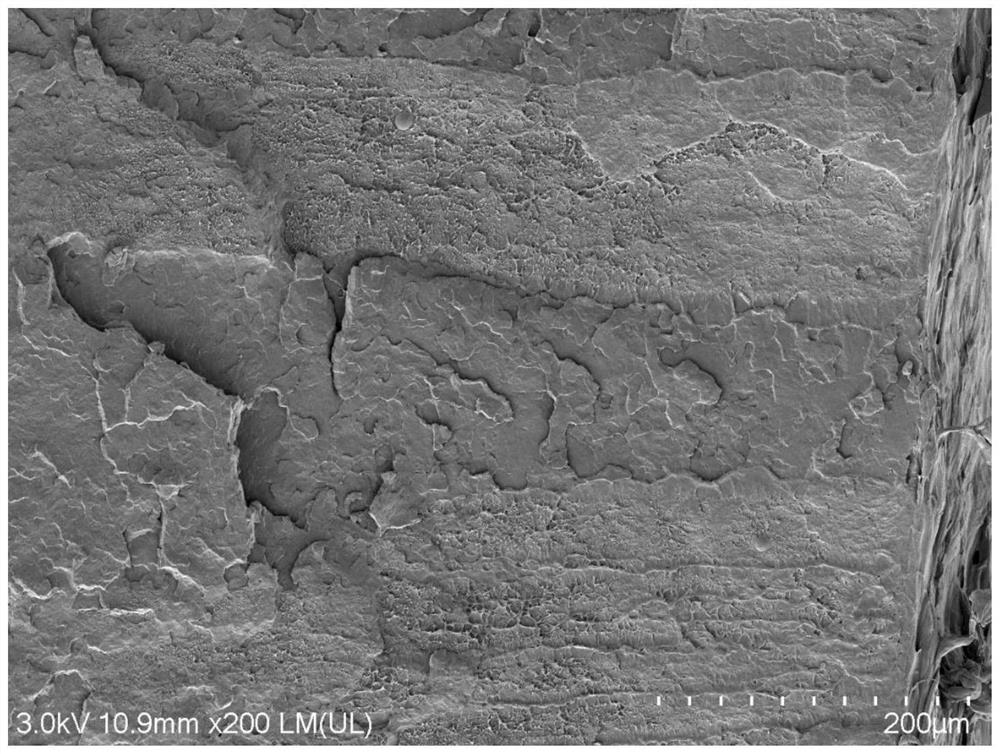

Image

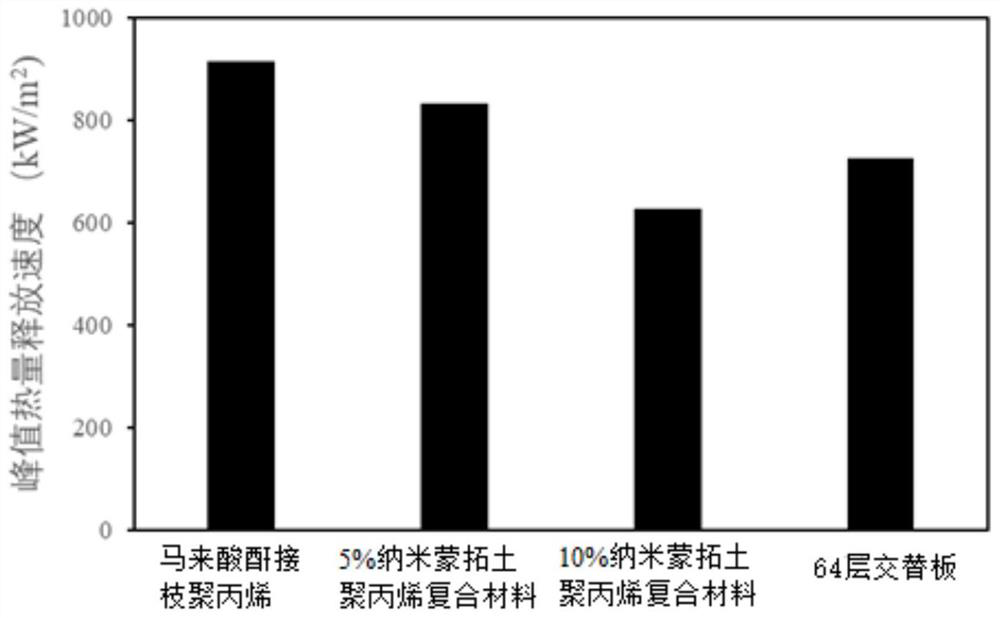

Examples

Embodiment 1

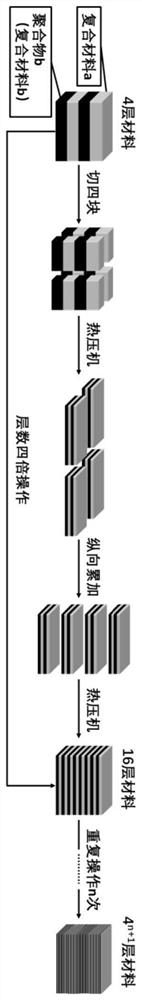

[0027] A method for preparing a fireproof material with an alternating multilayer structure, comprising the following steps:

[0028] S1: Weigh 900g of maleic anhydride-grafted polypropylene and 100g of nanometer montmorillonite to prepare 10% nanometer montmorillonite polypropylene composite material, dry it in an oven at 60°C for 12 hours, put it into a twin-screw extruder for melt blending and extrusion For granulation, the extrusion temperature is 180°C, the screw speed is 20rpm / min, weigh 35g of granules and heat press, the heat press temperature is 180°C, the pressure is 0MPa for 5min, the pressure is 5MPa for 5min, and the heat press treatment is 1mm× 20cm×20cm sheet a;

[0029] S2: Weigh 35g of polypropylene, and heat press according to the method of S1 to prepare a sheet b with a thickness of 1mm×20cm×20cm;

[0030] S3: Alternately place two thin plates a obtained in step S1 and two thin plates b obtained in step S2, and heat-press them into a four-layer alternating ...

Embodiment 2

[0033] A method for preparing a fireproof material with an alternating multilayer structure, comprising the following steps:

[0034] S1: Weigh 940g of maleic anhydride grafted polyethylene, 50g of nanometer montmorillonite and 10g of flame retardant, dry in an oven at 60°C for 12 hours, put them into a twin-screw extruder for melt blending and extrude granulation, and the extrusion temperature At 200°C, the screw speed is 30rpm / min, weigh 35g of granules and heat press, heat press temperature is 180°C, press 0MPa for 5min, and press 5MPa for 5min, heat press to obtain 1mm×20cm×20cm sheet a;

[0035] S2: Weigh 35g of polyethylene, and heat-press according to the method of S1 to obtain a sheet b with a thickness of 1mm×20cm×20cm;

[0036] S3: Alternately place two thin plates a obtained in step S1 and two thin plates b obtained in step S2, and heat-press them into a four-layer alternating plate of 4mm×20cm×20cm. The temperature of the hot press is 180°C and the pressure is 5MPa...

Embodiment 3

[0039] A method for preparing a fireproof material with an alternating multilayer structure, comprising the following steps:

[0040] S1: Weigh 950g of maleic anhydride grafted polyethylene and 50g of nanometer montmorillonite, dry in an oven at 60°C for 12 hours, put them into a twin-screw extruder to melt, blend, extrude and granulate, the extrusion temperature is 190°C, and the screw Rotational speed is 25rpm / min, weigh 35g granules and heat-press, hot-press temperature is 180℃, pressure 0MPa for 5min, pressure 5MPa for 5min, heat-press to obtain 1mm×20cm×20cm sheet a;

[0041] S2: Weigh 990g of polyethylene and 10g of flame retardant, and heat press according to the method of S1 to prepare a sheet b with a thickness of 1mm×20cm×20cm;

[0042] S3: Place the two thin plates a obtained in step S1 and the two thin plates b obtained in step S2 alternately, and heat-press them into a four-layer alternating plate of 4mm×20cm×20cm. The temperature of the hot press is 180°C, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap