Systematic grouting process for dynamic water foundation pit cofferdam

A systematic, cofferdam technology, applied in infrastructure engineering, construction, etc., can solve the problems of difficult application, long construction time, high equipment and process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

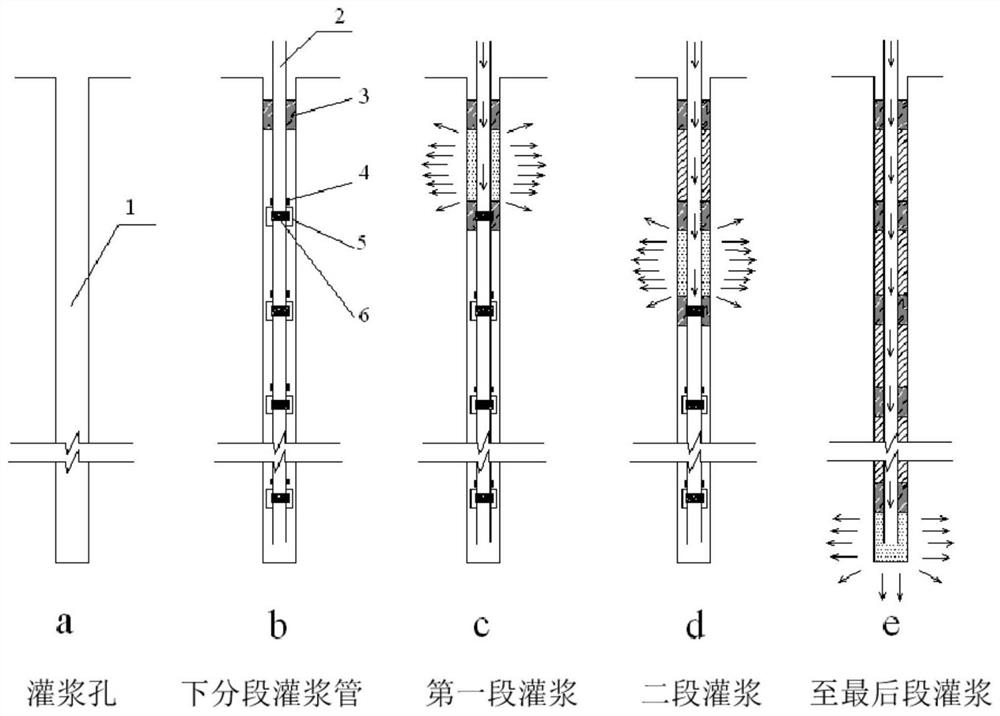

[0045] A systemic grouting process for cofferdams of dynamic water foundation pits; the process includes the following steps:

[0046] Step 100: drilling equipment positioning; the step 100 specifically includes the following steps:

[0047] Step 110: arrangement of grouting holes;

[0048] Step 120: Drilling the grouting hole according to the preset grouting depth;

[0049] Step 130: Reinforce and protect the grouting hole after completion.

[0050] The hole position deviation of the grouting hole in the step 110 shall not be greater than 10cm; the aperture of the grouting hole is Φ164mm-168mm; the step 130 uses a geotextile to block the nozzle, and the purpose of the step 130 is to use the exposed grouting pipe Geotextiles or woven bags will seal the mouth of the pipe tightly to prevent gravel and soil from entering the grouting pipe and affecting the grouting quality.

[0051] It needs to be further explained that the layout of all drilling holes shall be measured and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com