Terminal air conditioning system for multiple working conditions, control method and control device

An air-conditioning system and control method technology, applied in the direction of air-conditioning systems, applications, heating methods, etc., can solve problems such as terminal air-conditioning, large air volume in the input room, and large air duct resistance, etc., so as to improve human comfort and comprehensive energy efficiency The effect of improving and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

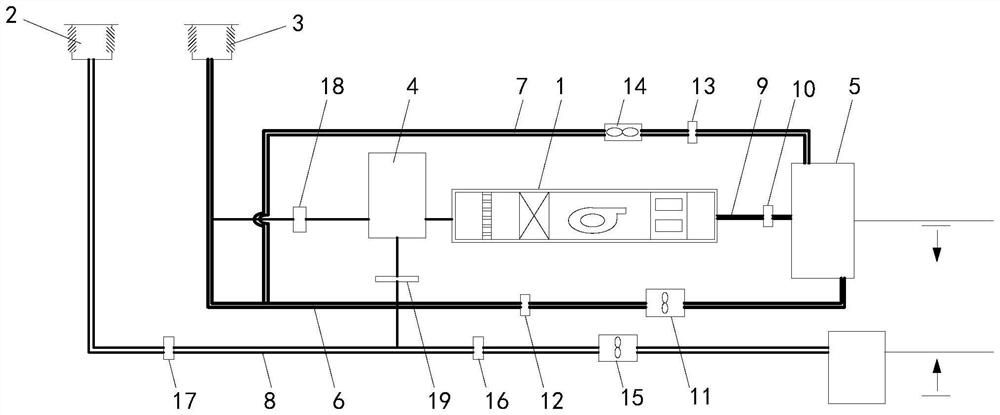

[0034] according to figure 1 As shown, this embodiment proposes a terminal air-conditioning system for multi-working conditions, including a combined air-conditioning unit body 1, an exhaust shaft 2, an air intake shaft 3, a fresh air duct 6, a winter air duct 7 and a return exhaust duct 8 , the system air duct of the combined air conditioning unit body 1 is provided with a fresh air duct 6 and a winter air duct 7, the winter air duct 7 is connected to the fresh air duct 6, and the fresh air duct 6 is connected to the air inlet shaft 3 , the return exhaust duct 8 is connected to the exhaust shaft 2 .

[0035] The fresh air duct 6 is provided with a fresh air blower 11 and a fresh air supply valve 12 , and the winter air duct 7 is provided with a winter air supply valve 13 and a winter fan 14 .

[0036] The combined air-conditioning unit body 1 is connected with a first air mixing chamber 4 and a second air mixing chamber 5, and the first air mixing chamber 4 is respectively c...

Embodiment 2

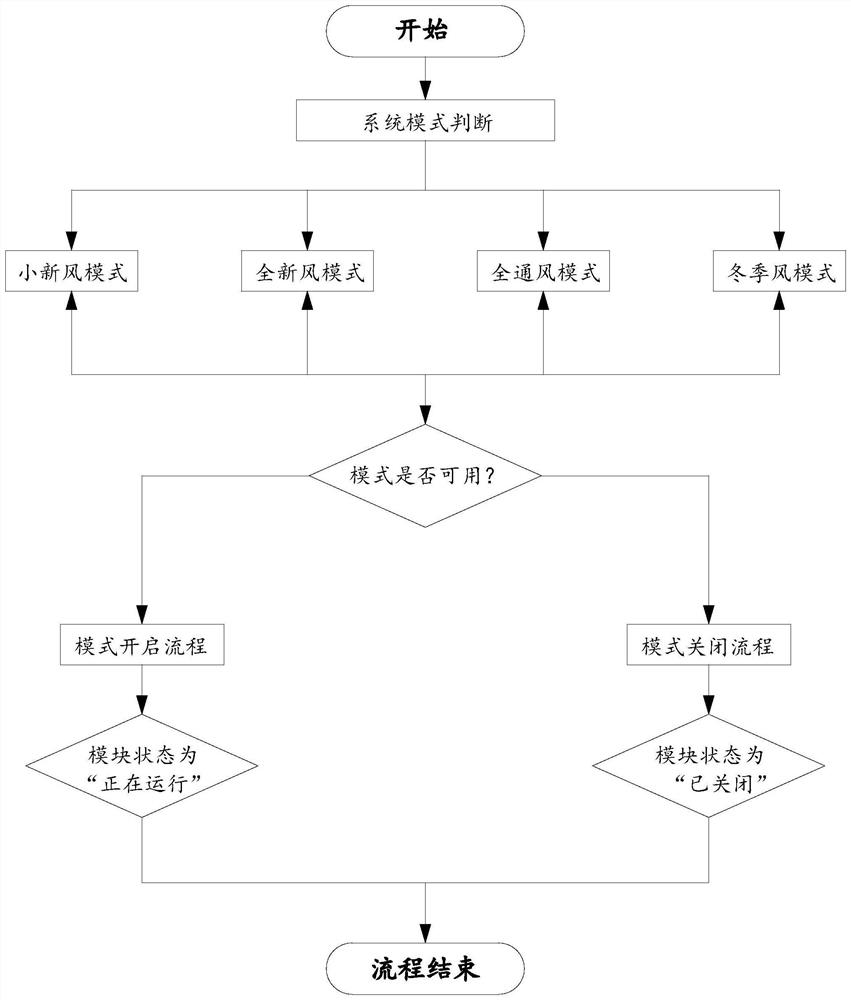

[0042] according to figure 2 As shown, this embodiment proposes a control method for a multi-working condition terminal air-conditioning system, including the following steps:

[0043] Obtain the outdoor air enthalpy value, indoor average enthalpy value, outdoor temperature, supply air temperature setting value, outdoor minimum temperature setting value and indoor dew point temperature parameters, judge the wind side system mode according to the above parameters, and control the terminal air conditioner according to the judgment results The system executes the corresponding wind side mode under the corresponding working conditions;

[0044] Specifically:

[0045] When the outdoor air enthalpy value Hw ≥ the indoor average enthalpy value Ha, the small fresh air mode will be implemented, the air module status will be "opening", and the delay reset operation will be performed simultaneously;

[0046] When the outdoor air enthalpy value Hw

Embodiment 3

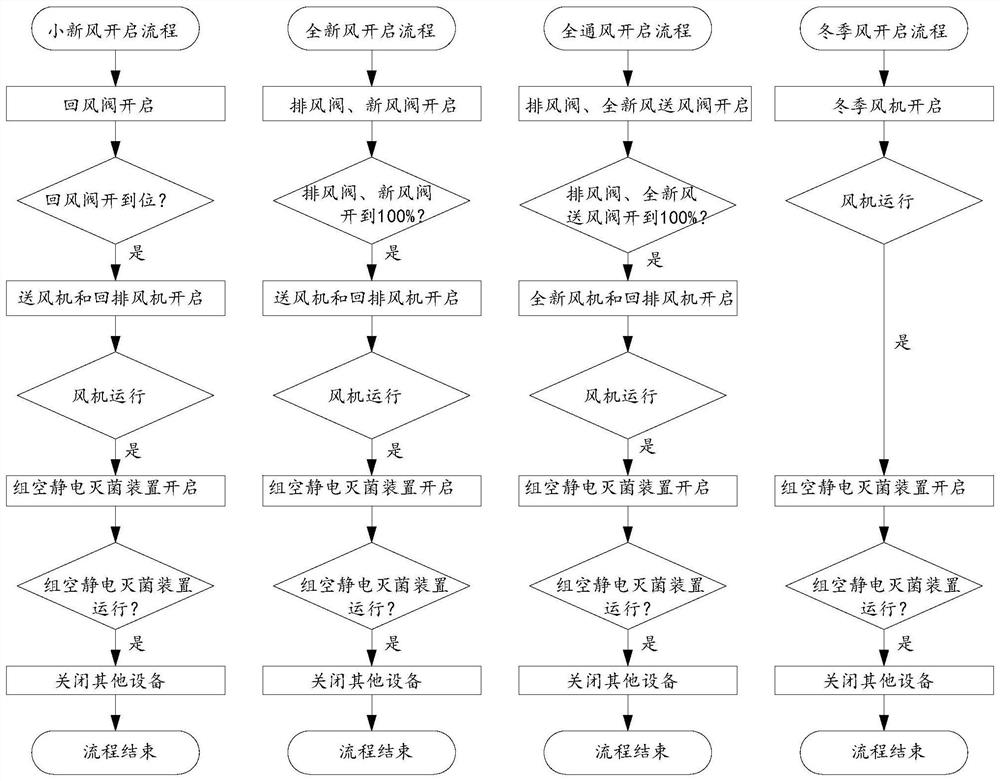

[0057] according to image 3 As shown, this embodiment proposes a control method for a terminal air-conditioning system for multi-working conditions. When the wind-side mode can be turned on, the subordinate modes included in the wind-side mode are controlled to run according to the control process of the corresponding mode. Specifically for:

[0058] When the small fresh air mode can be turned on, its control process is as follows:

[0059] The return air valve 19 is opened, and it is judged whether the return air valve 19 is opened to the maximum range;

[0060] When the air return valve 19 is opened to the maximum range, the air blower and the exhaust fan 15 of the combined air conditioning unit body 1 are controlled to perform an opening command;

[0061] When the air supply fan and the exhaust fan of the combined air conditioning unit body 1 feed back the running status, a command to start the group empty electrostatic sterilizer is issued;

[0062] When the group empt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com