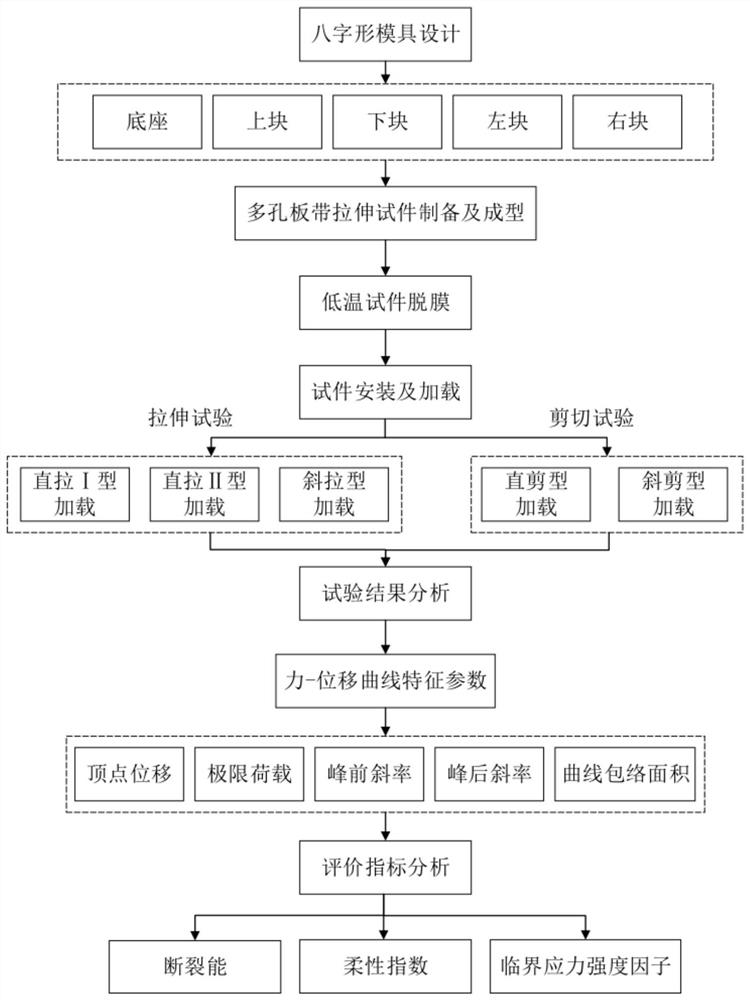

Tensile and shear test method for fiber-reinforced asphalt mortar perforated plate strip

A fiber reinforced, shear test technology, applied in the application of stable shear force to test material strength, strength properties, preparation of test samples, etc. and other problems to achieve the effect of improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

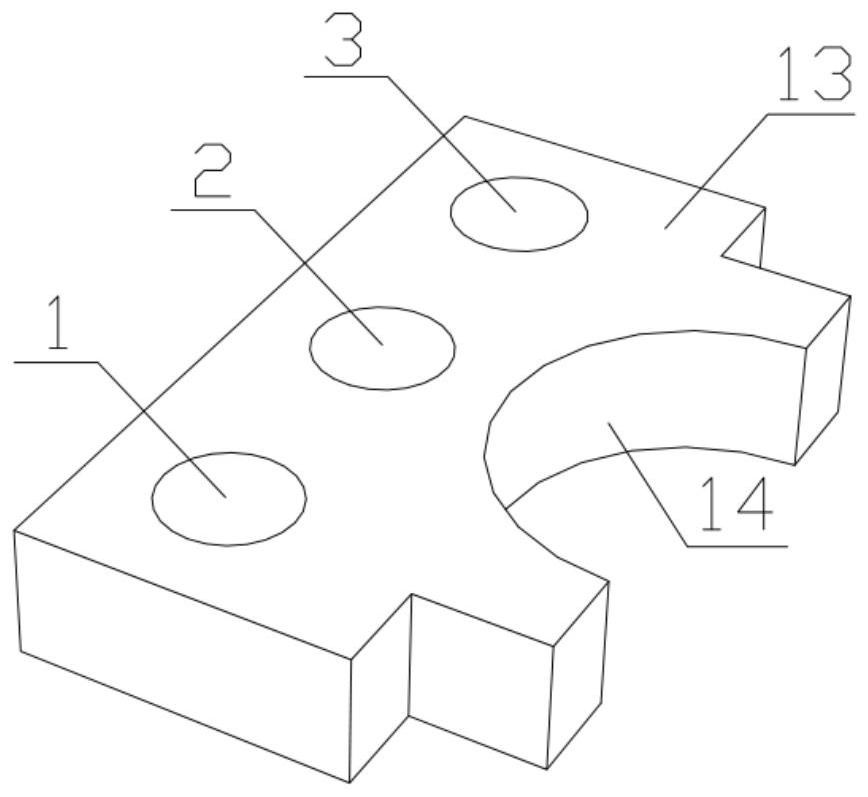

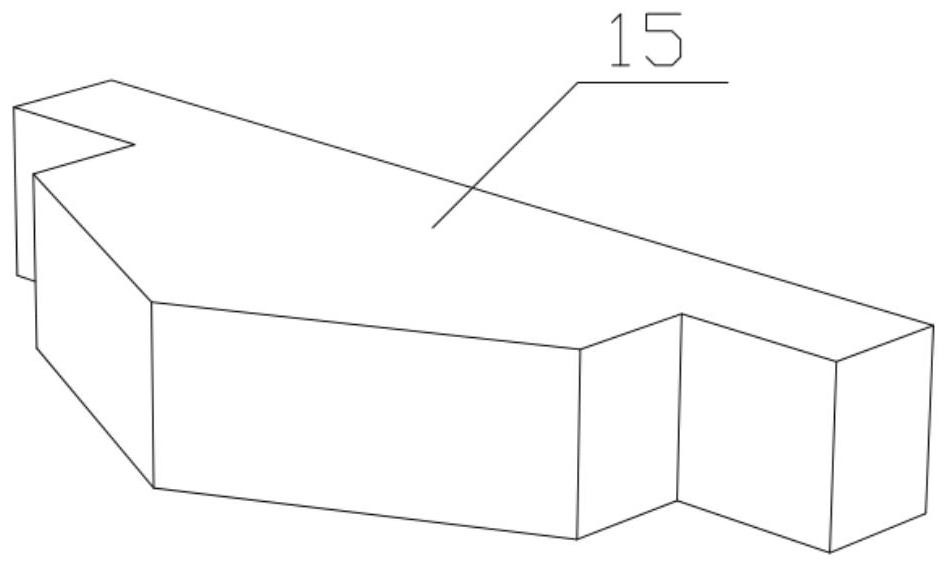

[0044] In this example, no fiber is added, and a test piece is prepared by using 50% mineral powder and 50% SBS modified asphalt. When loading, use straight-pull type I loading, select the No. 2 hole of the upper block 13, and the No. 8 hole of the lower block 18 to connect with the connecting block. The test results are shown in Table 1-Table 2.

Embodiment 2

[0046] In this example, 49% mineral powder, 49% SBS modified asphalt and 2% basalt fiber are used to prepare the test piece. When loading, use straight-pull type I loading, select the No. 2 hole of the upper block 13, and the No. 8 hole of the lower block 18 to connect with the connecting block. The test results are shown in Table 1-Table 2.

[0047] Table 1 Characteristic parameters of force-displacement curve

[0048]

[0049] Table 2 Calculation results of test data

[0050]

[0051] It can be seen from the table that the fracture energy, flexibility index and critical stress intensity factor of the asphalt mortar increase significantly after adding basalt fiber, so the enhancement effect of basalt fiber on the crack resistance of asphalt mortar is remarkable.

[0052] This test method provides a simple and feasible direct tensile test method for fiber asphalt mortar. The designed mold can cause stress concentration in the middle position of the specimen, and can ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com