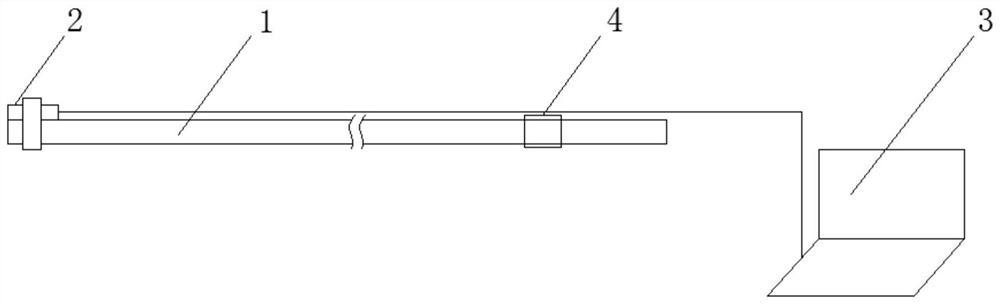

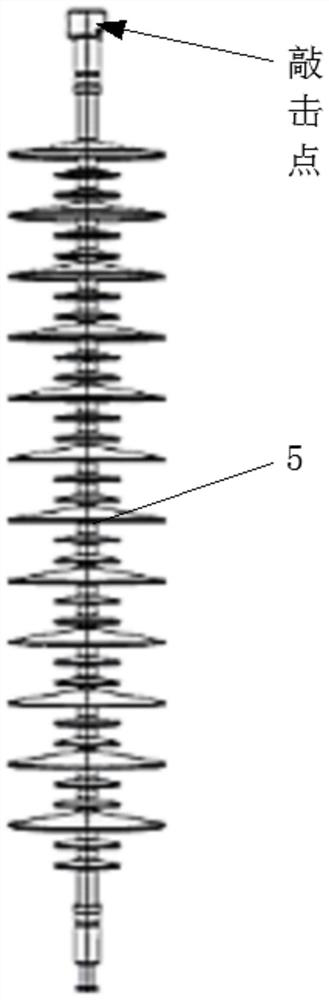

Device and method for detecting crisp and rotten defects of composite insulator core rod

A technology of composite insulators and detection devices, which is applied to measuring devices, using acoustic measurement for testing, measuring electricity, etc., can solve the problems of inability to judge the severity of decay intuitively, difficulty in online detection, complicated operation, etc., so that it is not easily affected by the outside world , Avoid economic losses, and the effect of accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

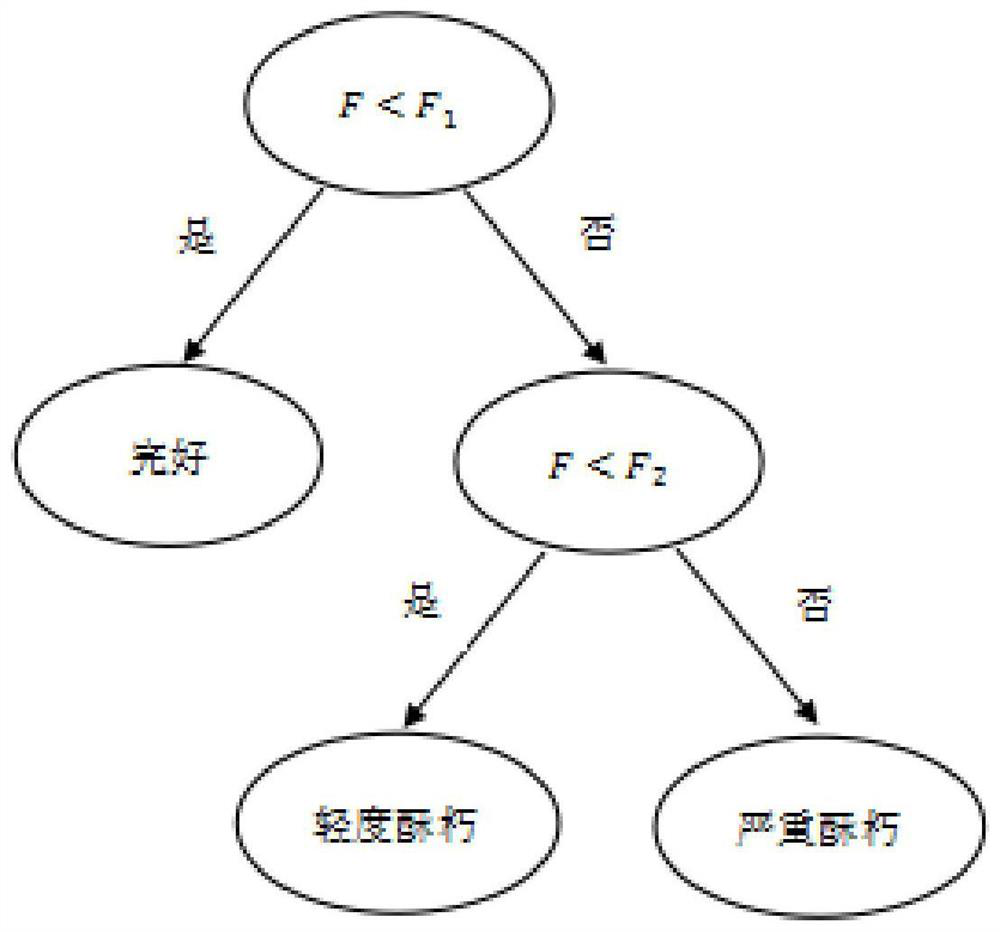

[0052] EXAMPLES: The technical principle of the present invention is that the structural system will generate natural vibration at a specific frequency in a particular frequency, and this particular frequency is called the inherent frequency of the structure, and the inherent frequency is not related to the external excitation. It is a structure. A inherent attribute, the inherent frequency of the structure is only affected by the distribution and mass distribution of the structure itself.

[0053] The differential equation from the simplest component described above can obtain the elastic modulus of the member bending rigidity EIE as a material, i is the secondary moment of the cross section, the unit length mass M, shear stiffness K s And the inherent frequency f caused by rotating inertia ρiρ for changes in material density i Change, EI, M, K s The changes caused by the change of ρi are near linear. The differential equation of the component is:

[0054]

[0055] When the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com