Energy-saving control circuit of engine-driven power generation and electric welding dual-purpose machine

An engine-driven, energy-saving control technology, applied in the control of generators, control of generators through magnetic field changes, control systems, etc., can solve problems such as high energy consumption, inability to reduce third harmonic damage, etc., to reduce noise and fuel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

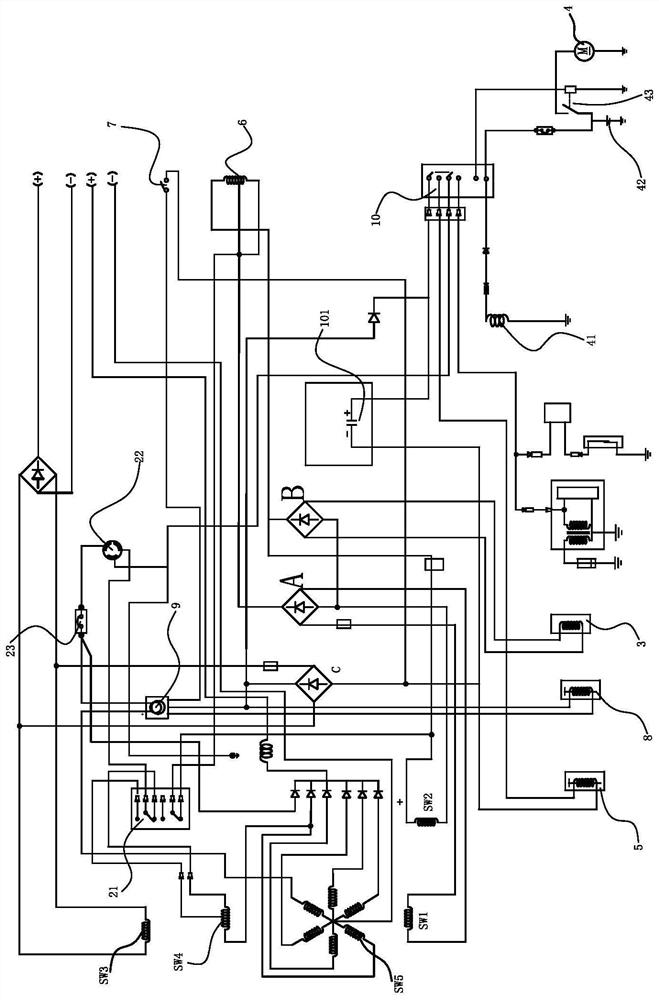

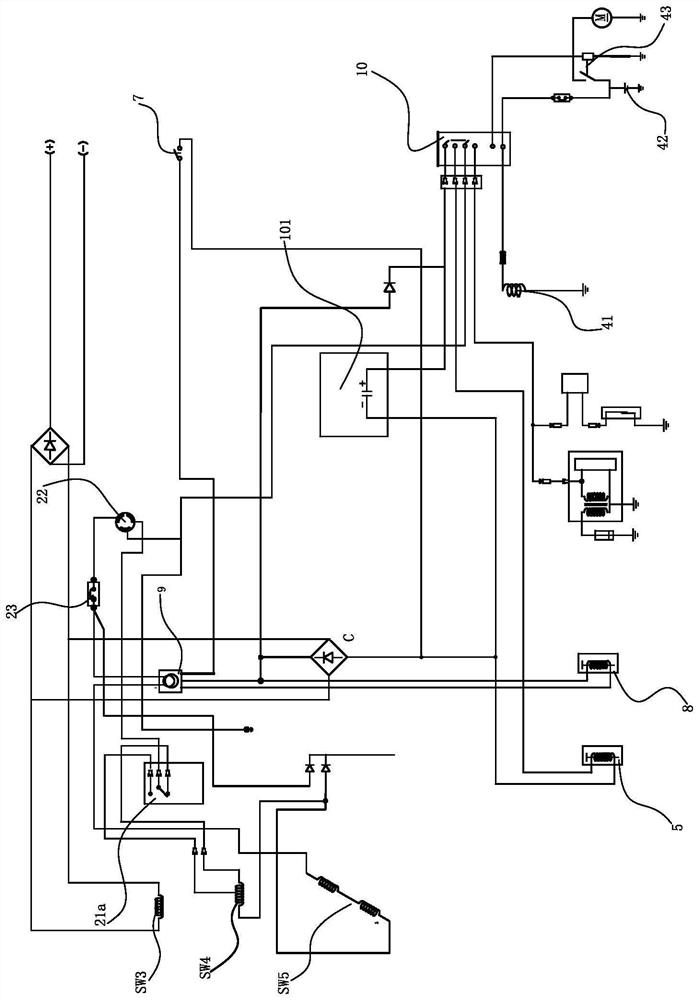

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

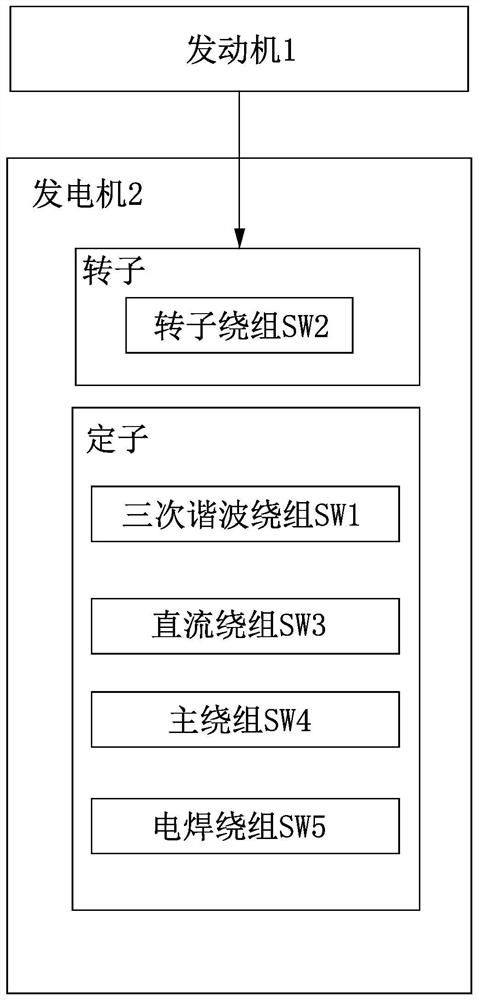

[0026] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, the energy-saving control circuit of the engine-driven electric welding dual-purpose machine includes a generator 2, an engine 1 for driving the generator 2 to generate electricity, and a magneto 3 connected to the engine 1. The generator 2 includes a The rotor winding SW2, the main winding SW4 set on the stator for outputting the generating current, the electric welding winding SW5 for outputting the welding current and the DC winding SW3 for power supply, the electric welding winding SW5 adopts a six-phase star connection, and the energy-saving control circuit also includes an idle speed The controller 9 and the control switch 21 for switching betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com