Self-cleaning method of surface cleaning system

A surface cleaning and surface cleaning device technology, applied in the self-cleaning field of the surface cleaning system, can solve problems such as poor cleaning effect, achieve the effect of improving cleaning effect, improving cleaning effect, and reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

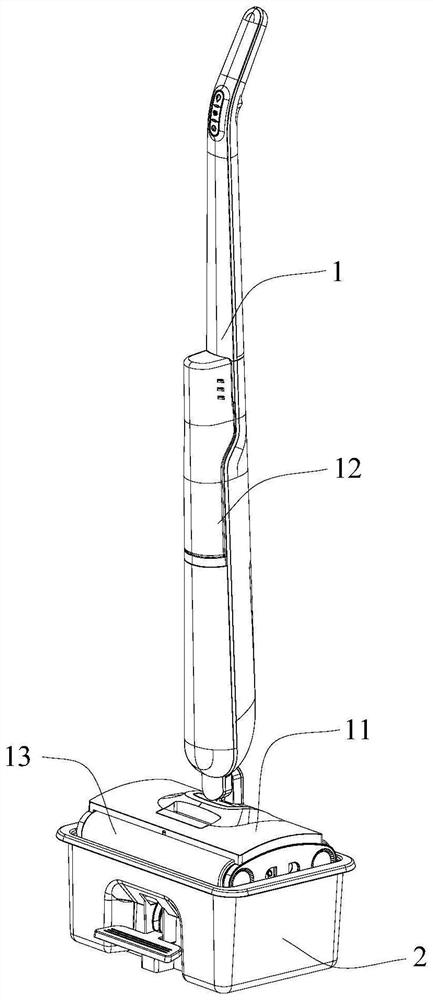

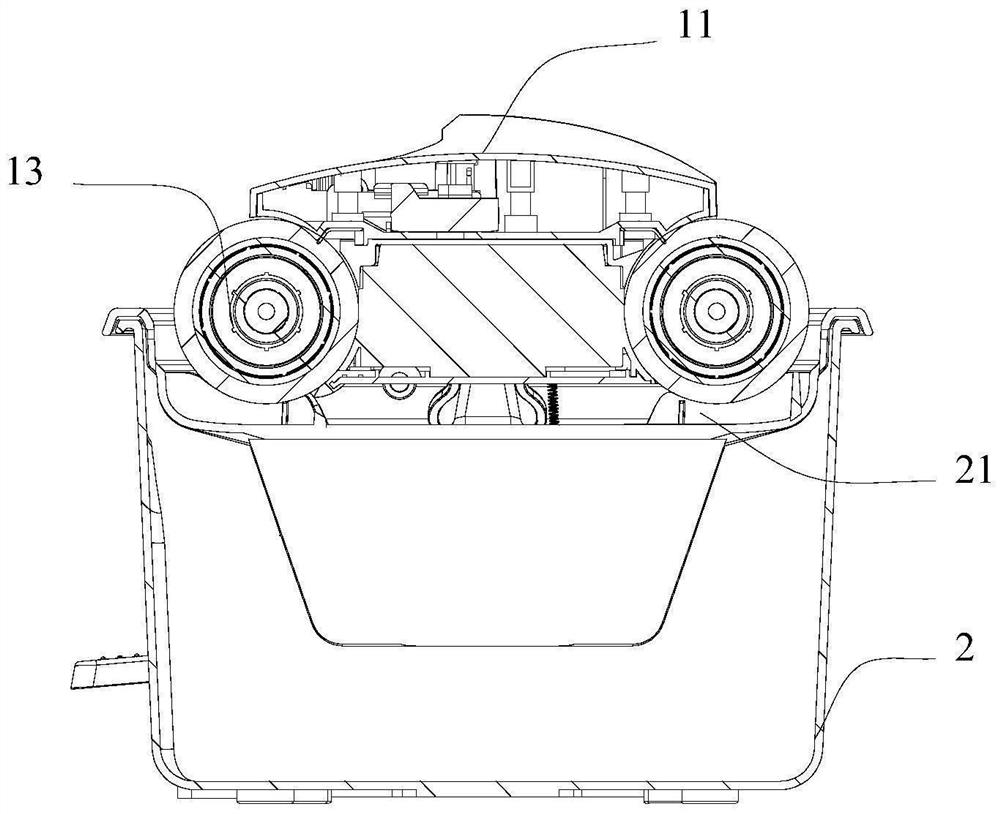

[0047] Such as Figure 1 to Figure 3 As shown, the surface cleaning system of this embodiment includes a surface cleaning device 1 and a cleaning assembly 2 , and the surface cleaning device 1 includes a cleaning head 11 , a body 12 and a cleaning roller 13 as a mopping member. Wherein, the body 12 is pivotally connected with the cleaning head 11 , the body 12 has a handle for the user to hold, and the user can hold the handle to control the movement of the surface cleaning device 1 . Cleaning roller 13 is provided with two, is arranged on the front and rear end of cleaning head 11 respectively, and cleaning roller 13 is pivotally connected with cleaning head 11, and surface cleaning device 1 is provided with driving motor to drive cleaning roller 13 to rotate, and the cleaning roller 13 of rotation can treat Clean surface for cleaning.

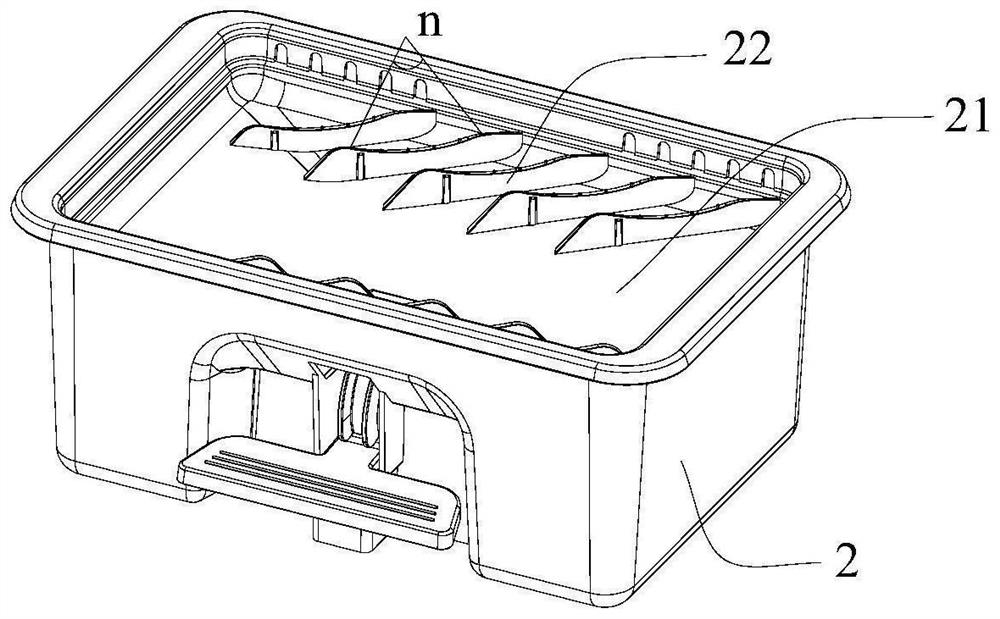

[0048] Continue to refer to Figure 1 to Figure 3 As shown, the cleaning assembly 2 is provided with a cleaning tank 21, and a scraping ri...

example 2

[0056] As example 2: the drive motor is provided with multi-polar magnets, and the drive motor is provided with Hall elements around it. During the rotation of the drive motor, the different polarities of the driven magnets pass through the Hall elements, and the change of polarity makes the Hall elements The element generates a signal, therefore, by making the distance between the polarities equal to the angle that needs to be turned, the control module of the surface cleaning device 1 adjusts the rotation direction of the cleaning roller 13 according to the signal of the Hall element, and at the same time, the recording Hall element generates The number of times of the signal, 2 signals represent that the cleaning roller 13 has performed a cycle of turning over the angle a along the first direction of rotation and turning over the angle b along the second turning direction. When the cycle is 20 times, the cleaning roller 13 has turned over at least one turn, then record When ...

no. 2 example

[0067] Although not shown in the figure, different from the first embodiment, the self-cleaning method of this embodiment includes:

[0068] The first cleaning step: make the cleaning roller rotate and clean in the first rotation direction in the cleaning tank until the cleaning roller rotates through the angle a;

[0069] The second cleaning step: make the cleaning roller rotate and clean in the second rotation direction in the cleaning tank until the cleaning roller rotates through the angle b;

[0070] The first cleaning step and the second cleaning step are carried out in a cycle. After the first cleaning step and the second cleaning step are executed in a cycle, the cleaning roller is rotated to the first rotation direction by an angle a, so that the cleaning roller is relatively The position has rotated at least one turn.

[0071] Specifically, in this embodiment, the angle a is equal to the angle b, because the angle a is equal to the angle b, so each time the cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com