A handicraft production process combining graphite-organic compound

An organic compound and production process technology, applied in special decorative structures, decorative arts, decorative structures, etc., can solve problems such as excess waste, affecting the accuracy of raw material mixing ratio, etc., to achieve full utilization, prolong apparent life, and improve fully The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

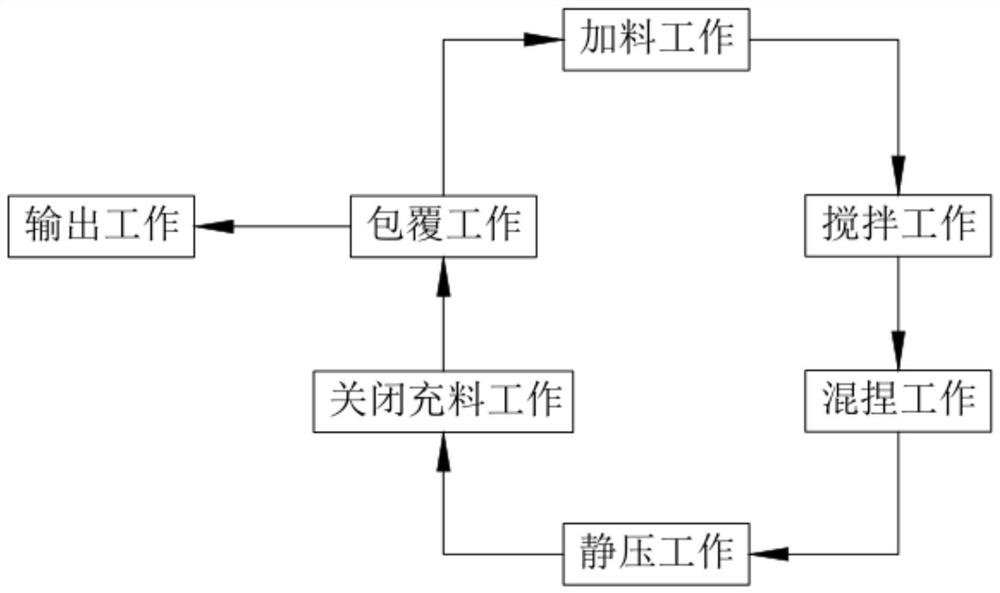

[0070] Such as figure 1 Shown, a kind of handicraft production technique that graphite-organic compound combines, comprises:

[0071] Step 1, feeding work, first start the driving member 13 to drive the rotating disk 11 to rotate intermittently, when the feeding station 11a of the rotating disk 11 is driven to the bottom of the forming cylinder 621 of the bearing assembly 62, the graphite of material A and the organic compound of material B are respectively from Material A feeding bin 21 and material B feeding bin 22 enter into the forming cylinder 621, and start the heater 625 at the same time;

[0072] Step 2, stirring work, the driving member 13 drives the rotating disk 11 to continue to rotate, the mixing station 11b of the rotating disk 11 is transmitted to the bottom of the forming cylinder 621 of the bearing assembly 62, the first cylinder 32 is activated, and the stirring shaft 35 is driven by the rotating shaft 33 Down to the inner wall of the forming cylinder 621, t...

Embodiment 2

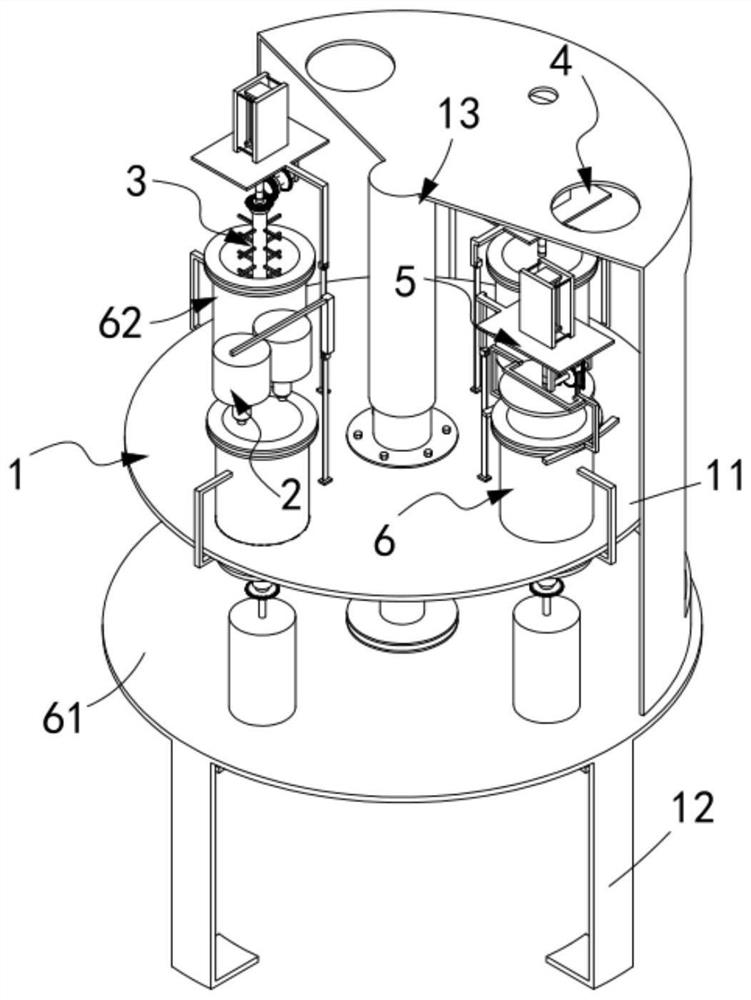

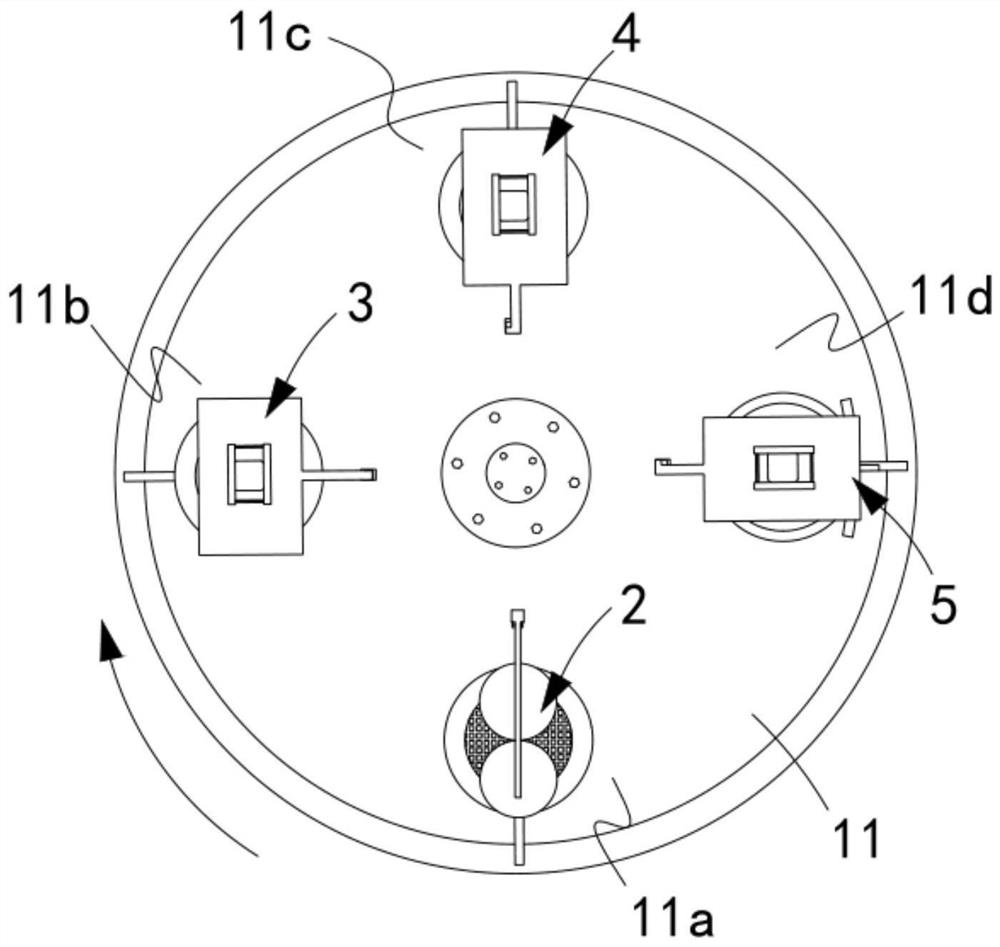

[0089] Such as figure 2 , Figure 5 with Image 6 Shown, a kind of handicraft production equipment that graphite-organic compound combines, comprises:

[0090] A driving mechanism 1, the driving mechanism 1 includes a rotating disk 11 and a driving member 13 installed on the frame 12 and used to drive the rotating disk 11 to rotate in a circle, and the rotating disk 11 is sequentially provided with feeding materials along the circumferential direction Station 11a, mixing station 11b, primary static pressure station 11c and cladding station 11d;

[0091] A feeding mechanism 2, the feeding mechanism 2 is installed on the rotating disk 11 and is located directly above the feeding station 11a;

[0092] A stirring mechanism 3, the stirring mechanism 3 is installed on the rotating disk 11 and is located directly above the mixing station 11b;

[0093] A static pressure mechanism 4, the static pressure mechanism 4 is installed on the rotating disk 11 and is located directly above...

Embodiment 3

[0123] Such as Figure 10 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0124] further, such as Figure 10 As shown, the lower end of the receiving container 623 is an open-cover structure;

[0125] The bottom cover of the receiving dish 623 is provided with an outlet 626, a ring rack 627 is fixedly arranged between the mixing station 11b and the primary static pressure station 11c, and an on-off valve 628 is arranged on the outlet 626 , the switch valve 628 is provided with a transmission gear 629 for driving the switch valve 628 to switch, and the transmission gear 629 is engaged with the ring rack 627;

[0126] The c material feeding bin 620 is communicated with the outlet 626 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com